Garbage press-drying incineration device

An incineration device and garbage technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of inconvenient replacement of electric heating tubes, burning of moisture in garbage, etc., and achieve the effect of easy operation and simple replacement steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

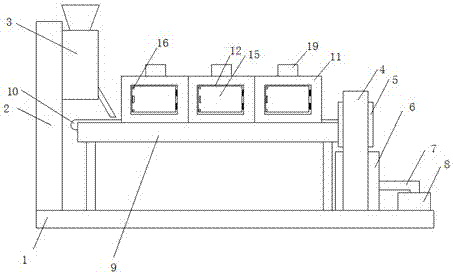

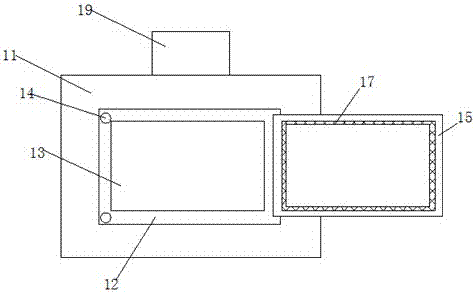

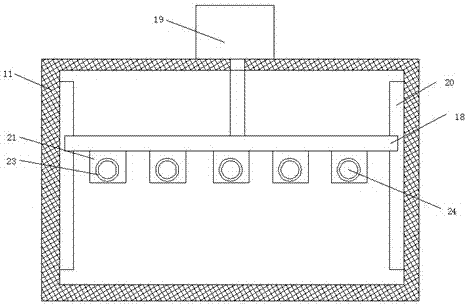

[0023] refer to Figure 1-4 , the present embodiment proposes a rubbish dry incineration device, including a rectangular placement seat 1, a mounting vertical plate 2 installed on one side of the top of the placement seat 1, and a U-shaped installation frame 4 installed on both sides of the top of the placement seat 1, Garbage extruding equipment 3 is installed on the top of the installation vertical plate 2 near the U-shaped mounting frame 4. The inboard of the U-shaped mounting frame 4 is equipped with a cutting device 5, and the bottom of the cutting device 5 is provided with an incineration device installed on the top of the placement seat 1. The furnace 6 is provided with a frame 9 installed on the top of the placement seat 1 between the vertical plate 2 and the U-shaped mounting frame 4, and the top of the frame 9 is welded with three drying boxes 11 arranged in sequence from left to right, The bottom of the drying box 11 is provided with an opening, and one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com