Construction method of super-large-section deep tunnel and accessory structure thereof

A technology of extra-large section and ancillary structures, applied in tunnels, tunnel linings, earth-moving drilling and mining, etc., can solve the problems of slow excavation and large vibration of extra-large-section tunnels and their ancillary structures, and achieve the advantages of small vibration, reduced vibration, and accelerated fixing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

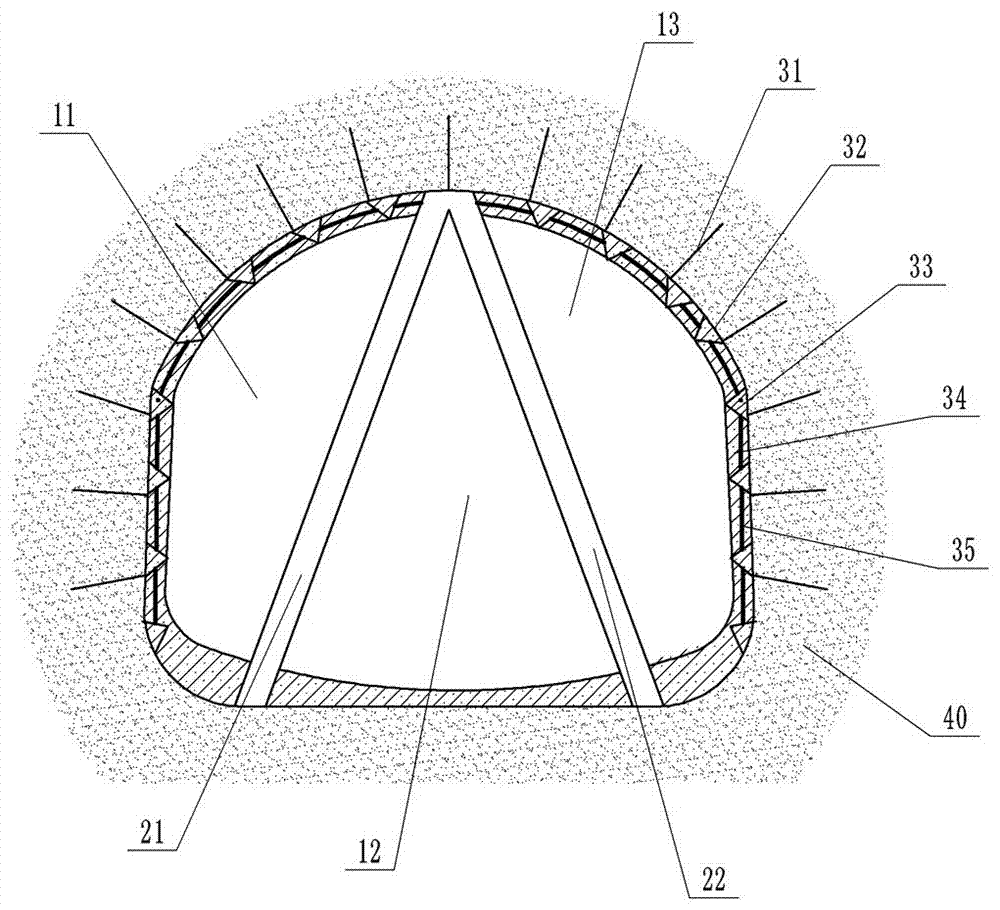

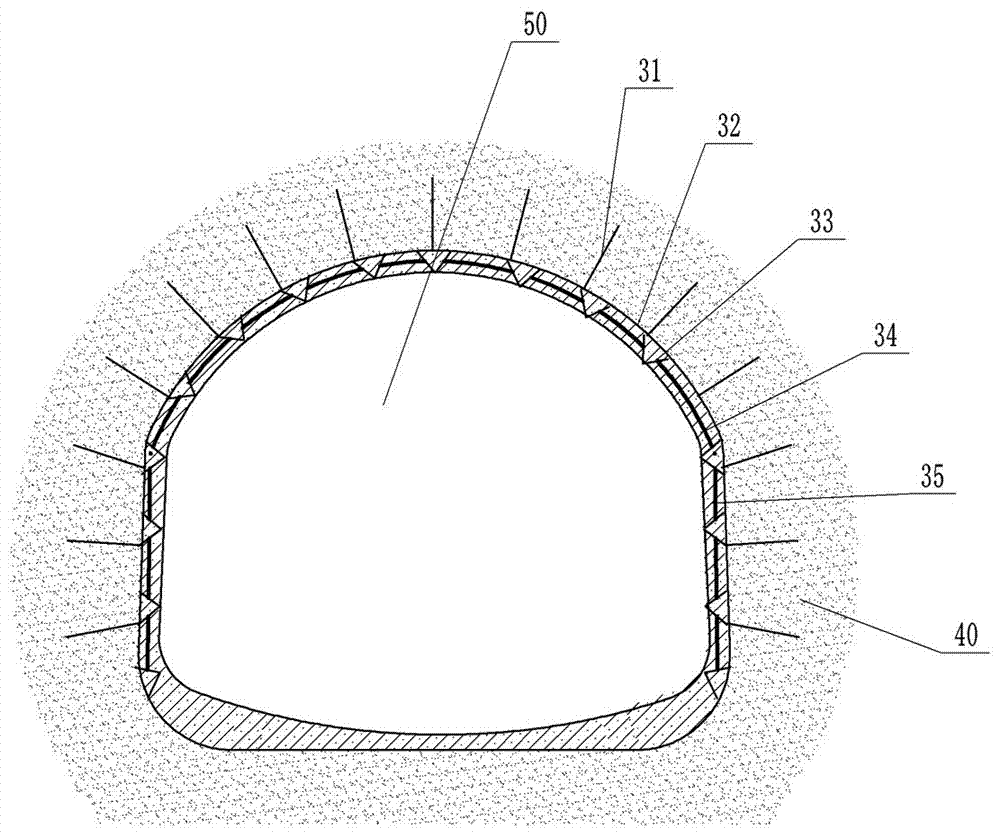

[0024] The reference signs in the drawings of the description include: left area 11, main area 12, right area 13, left partition layer 21, right partition layer 22, anchor rod 31, steel mesh 32, steel frame 33, concrete 34, reinforcement bar 35 , rock formation 40 , tunnel 50 .

[0025] like figure 1 , figure 2 As shown, a construction method for an extra-large cross-section deep-buried tunnel and ancillary structures includes the following steps:

[0026] (1) Divide the section of the tunnel 50 from the left side into the left area 11, the main area 12 and the right area 13, such as figure 1 As shown, a left partition layer 21 is provided between the left region 11 and the main region 12, and a right partition layer 22 is provided between the main region 12 and the right region 13; the upper end of the left partition layer 21 and the upper end of the right partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com