Power cable management robot

A power cable and robot technology, applied in the field of power cable hosting robots, can solve problems such as limited pipeline length, time-consuming and laborious threading, and inability to turn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

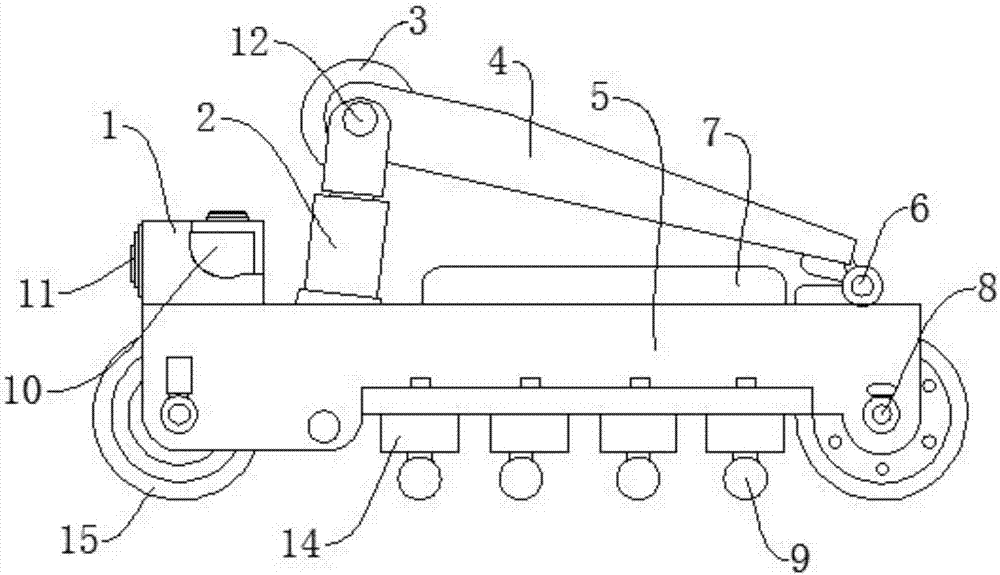

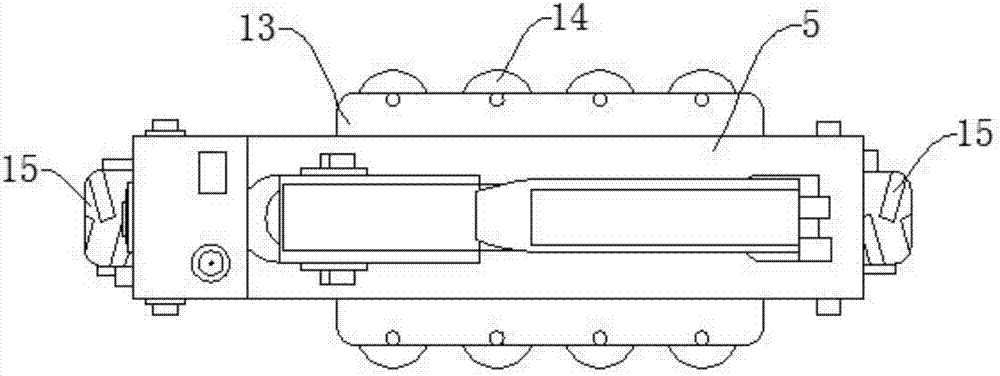

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Such as Figure 1-Figure 2 As shown, the power cable hosting robot includes a main frame 5, a support arm 4, a side wing 13 and a control box 1. Two anti-skid tires 15 are installed on the bottom of the main frame 5, and a hub is installed inside the anti-skid tire 15 at the back. Motor 8, the side wings 13 are installed on the two sides of the main frame 5, two rows of rollers 14 are installed on the side wings 13, a secondary wheel 9 is installed at the bottom of each of the rollers 14, the main frame 5 The top of the battery pack 7 is installed, the front of the battery pack 7 is provided with a spring strut 2, the support arm 4 is installed on the top of the spring strut 2 through a rotating shaft 12, the support arm 4 and the spring A support wheel 3 is installed in the middle of the rotating shaft 12 connected by the strut 2, and the other end of the support a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com