Electrode structure and method of manufacture thereof

An electrode structure and battery technology, applied in the direction of electrode manufacturing, spraying manufacturing, battery electrodes, etc., to achieve the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

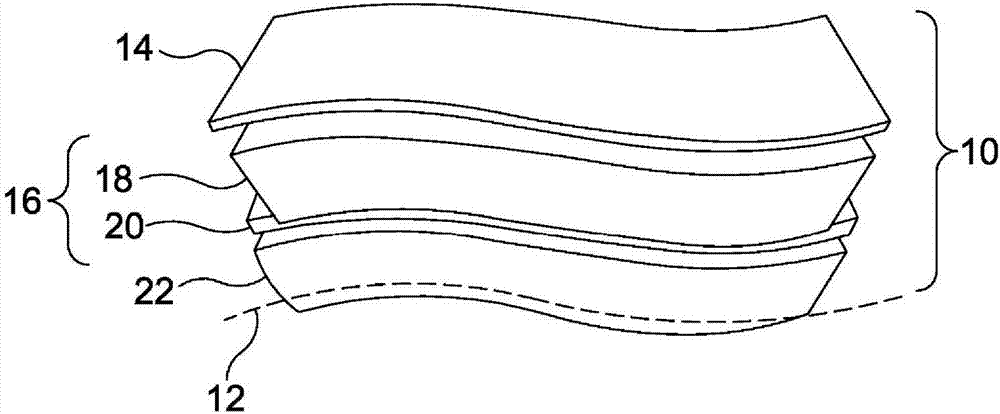

[0050] figure 1 One half 10 of a supercapacitor cell is schematically shown. The complete cell comprises a similar or identical other half of the supercapacitor cell (not shown), which would be arranged in a mirror image on the opposite side of the line or plane of symmetry 12 . Cell 10 includes a first electrically conductive current collecting tab 14 carrying an electrode 16 . Electrode 16 includes two layers. The first layer 18 adjacent to the current collector 14 is a layer comprising a composite of a high weight percent (wt%) conductive carbonaceous material and a low wt% electrochemically active metal oxide to provide high double-layer charge storage capability. The second layer 20, adjacent to the first layer 18, comprises a composite of a high wt% high surface area porous electrochemically active metal oxide and a low wt% conductive carbonaceous material. This layer 20 serves to catalyze the redox reaction between the electrode 16 and the electrolyte 42 . Proton (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com