Automatic tensioning type generator and automobile

A generator and tensioning technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as difficulty in tensioning generators, and achieve the effects of saving time and external force, convenient use and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

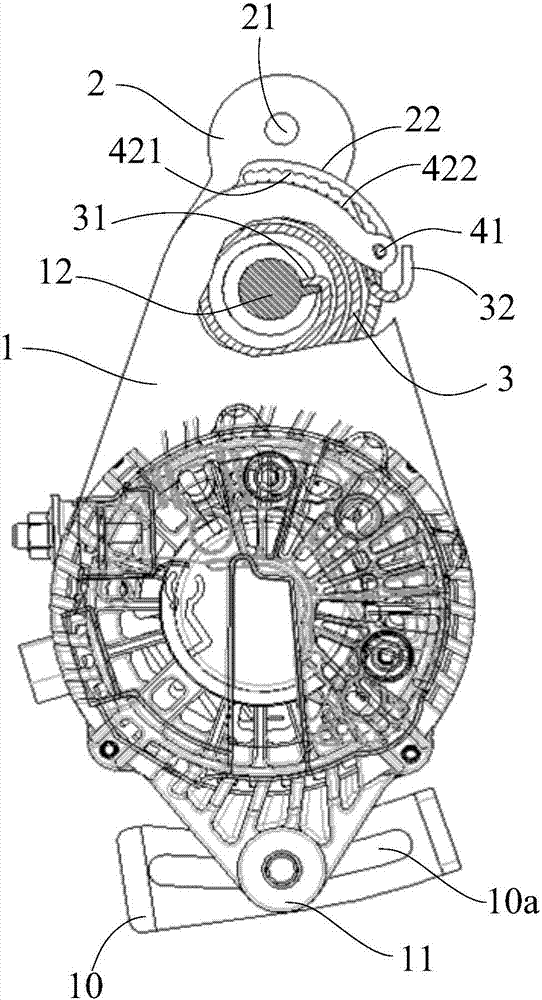

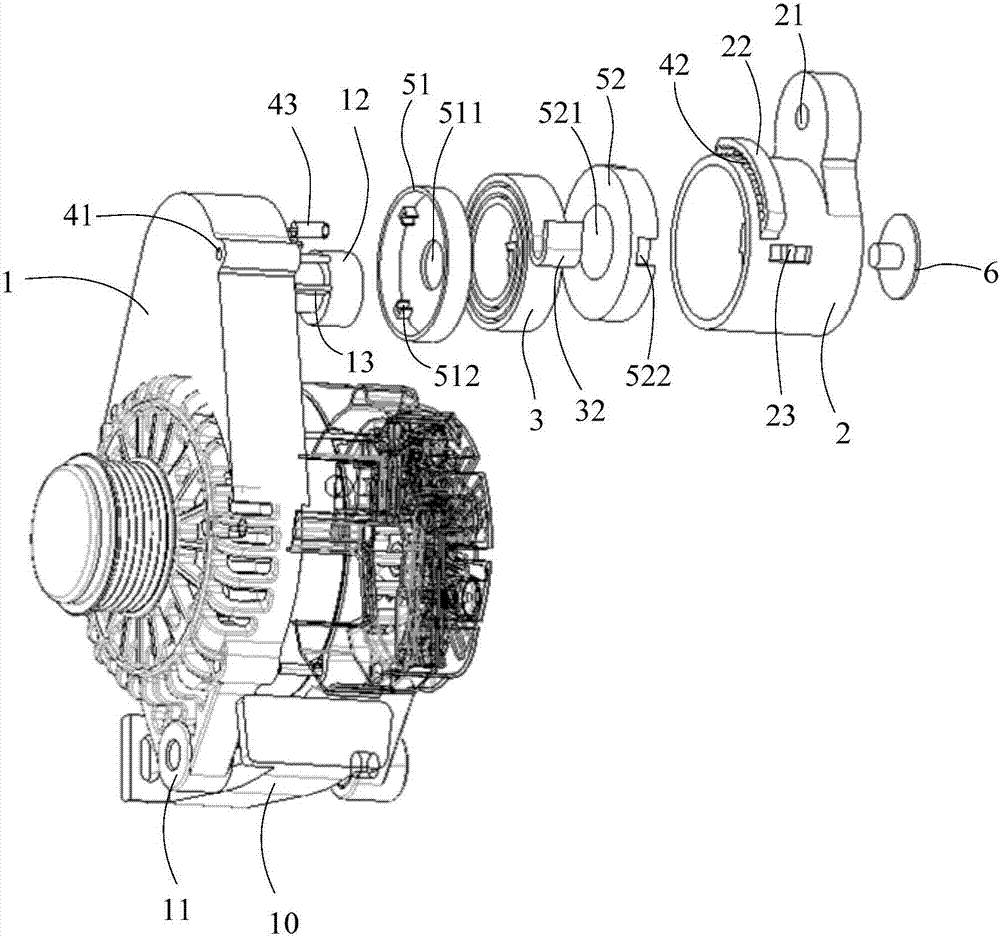

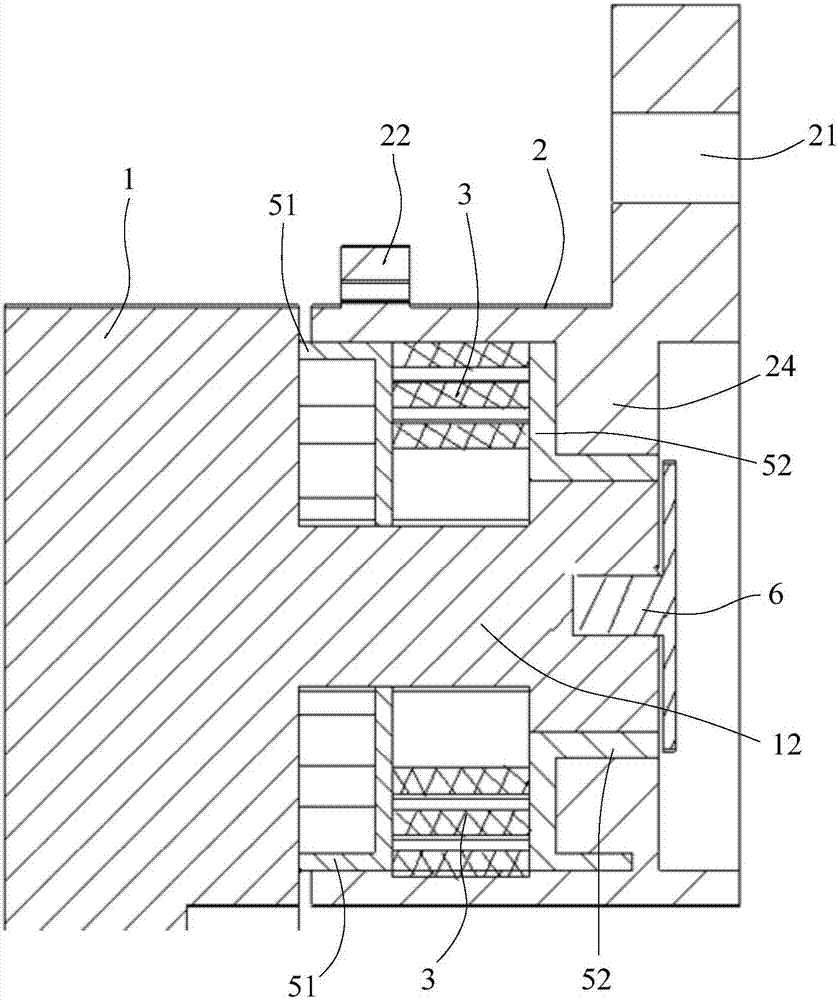

[0058] figure 1 It is a front view of an automatic tension generator provided by an embodiment of the present invention. figure 2 An exploded view of the structure of the self-tensioning generator provided by an embodiment of the present invention. image 3 A sectional view of an automatic tension generator provided by an embodiment of the present invention. Figure 4 An enlarged view of a partial structure of an automatic tension generator provided by an embodiment of the present invention. Refer to attached figure 1 To attach Figure 4 As shown, this embodiment provides an automatic tensioning generator, including an end cover 1, a base 2, an elastic member 3, and a positioning assembly;

[0059] The top of the base 2 is provided with an upper fulcrum 21 , and the base 1 is connected with the cylinder block or the cylinder head of the engine through the upper fulcrum 21 . The bottom of the end cover 1 is provided with a lower hanging angle 11 that can slide in the lowe...

Embodiment 2

[0072] This embodiment provides an automobile, including a vehicle body, on which the automatic tension generator provided in the above embodiment is installed, and the upper fulcrum of the generator is connected with the cylinder block or the cylinder head of the engine.

[0073] The automatic tension generator in this embodiment has the same structure as the automatic tension generator provided in Embodiment 1, and can achieve the same technical effect, so details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com