Motor device for fixing driving magnet

A fixed drive and motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of drive magnet deviation, looseness, loss, drive magnet flying off, etc., to reduce maintenance probability and ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

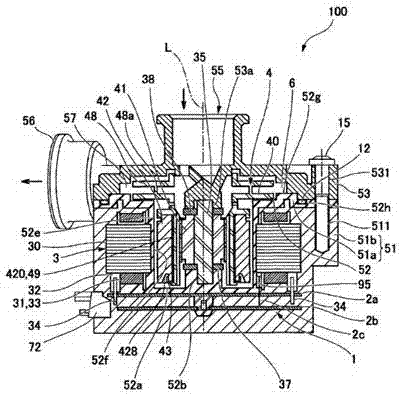

[0011] In the motor of this embodiment, since the engaging portion 445 covering the other end surface 422 of the driving magnet 42 is formed on the front end portion 440 of the magnet mounting portion 44 , axial movement of the driving magnet 42 can be reliably prevented. In addition, since the anti-idling convex portion 45a of the seat portion 45 fits in the anti-idling concave portion 42a formed on the one end surface 421 of the driving magnet 42, the driving magnet 42 can be reliably prevented from rotating around the axis. On the side of the seat 45, the small-diameter portion 426a of the driving magnet 42 is surrounded by the cylindrical portion 455 provided on the seat 45 itself to prevent the scattering of the driving magnet 42; A magnet scattering preventing concave portion 428 is provided radially outward from the inner peripheral edge, and a magnet scattering preventing convex portion fitted in the magnet scattering preventing concave portion 428 is formed on the seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com