Hollow inclusion crustal stress measurement self-sealing multi-aperture universal high pressure confining pressure rate meter

A hollow inclusion, self-sealing technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as pressure rise, single equipment can not meet the needs of multi-caliber core test, etc. To achieve the effect of stable confining pressure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

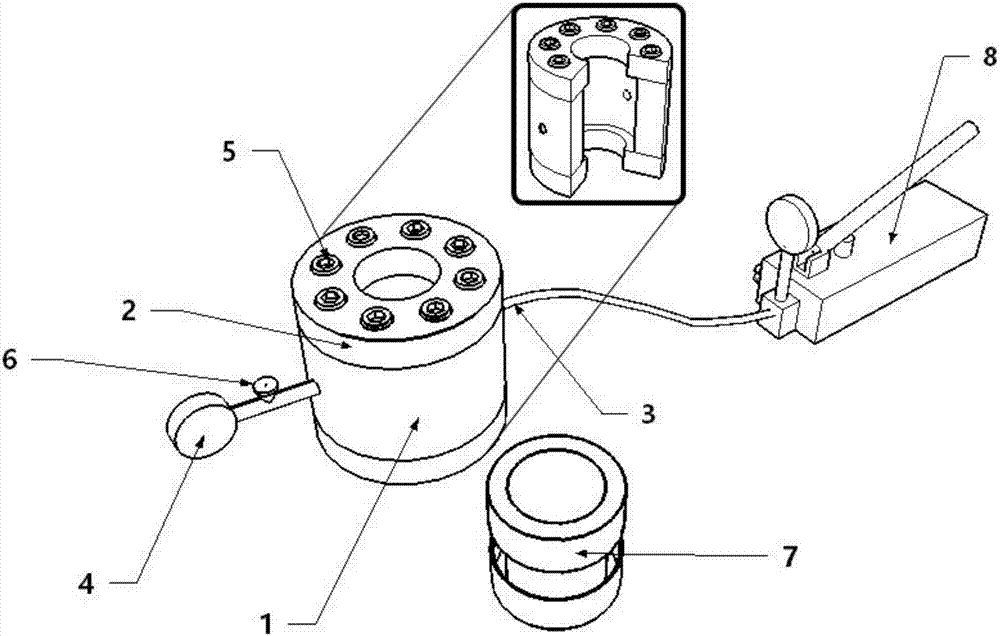

[0021] The invention provides a self-sealing multi-diameter general-purpose high-pressure confining pressure calibrator for measuring the ground stress of a hollow inclusion.

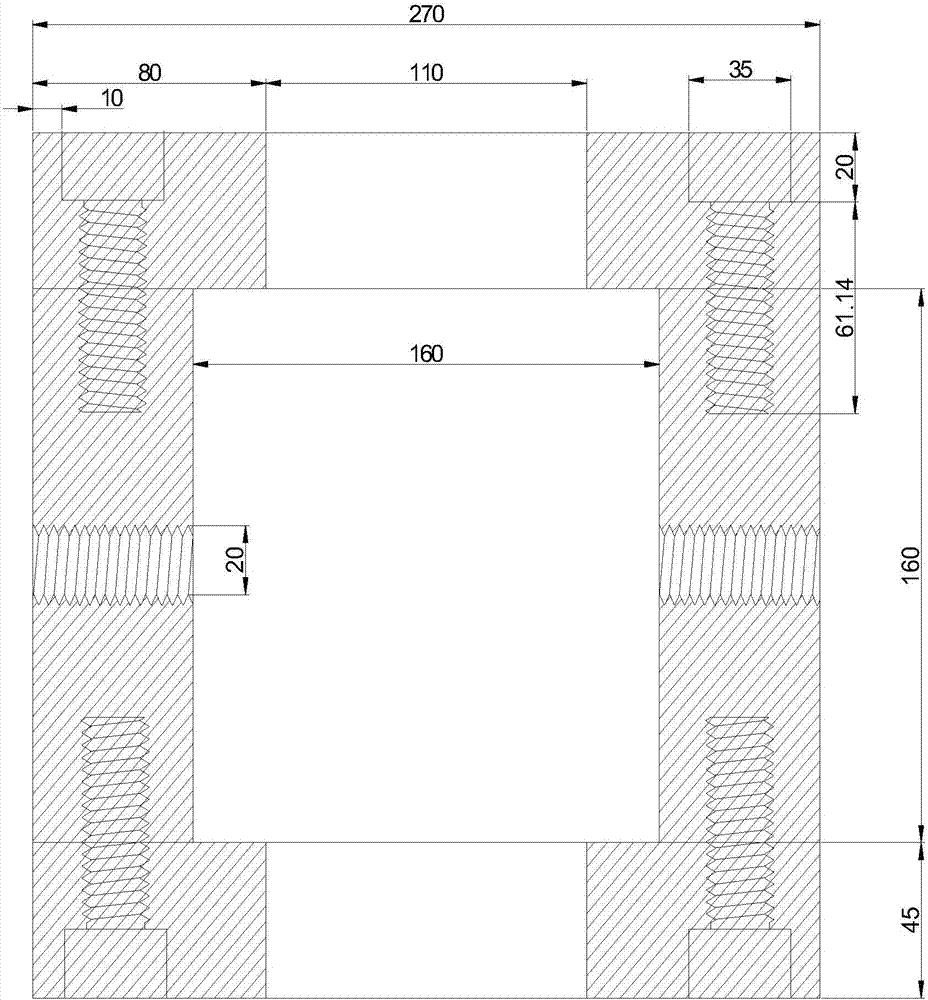

[0022] like figure 1 As shown, the high-pressure confining pressure calibrator includes a high-pressure confining pressure calibrator cabin 1, a hatch cover 2, a rubber sheath 7 and a high-pressure hand pump 8; Cover 2 is a hatch cover 2 that expands outwards. The hatch cover 2 has a concentric hole equal to the inner diameter of the rubber sheath 7; The height of the body 1 is the same as that of the rubber holster 7; an oil inlet and an exhaust port 6 are arranged on the cabin body 1 of the high-pressure confining pressure gauge, the oil inlet is connected with the high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com