A method of making seamless briefs

A technology of seamless triangle and production method, applied in the field of garment weaving, can solve the problems of many stitches, high sewing cost, discomfort, etc., and achieve the effects of reducing the sewing process, improving the processing efficiency and improving the comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

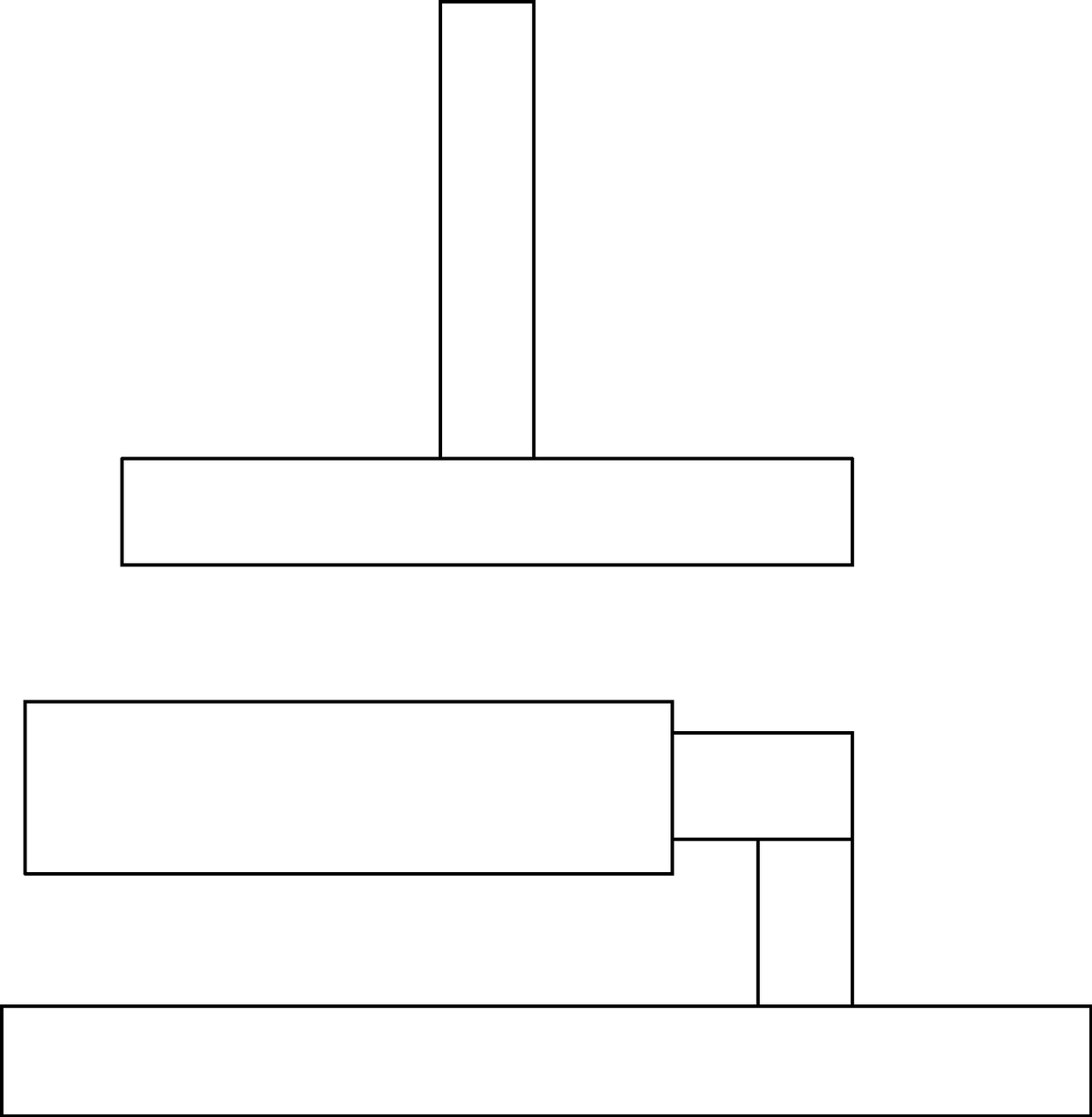

Image

Examples

Embodiment 2

[0014] Embodiment 2, a method for making seamless briefs, comprising the following steps: A. Weaving and forming: first weave the waist with the front tie method, the waist is a rib weave, the waist is double-layered after the tie, and 140 denier elastic, and then weave the front and rear trousers. After the trousers are finished, the front crotch is then made of the front body, the back is made of the back crotch, and 60 cotton yarns are woven into the front crotch to make loops. The foot of the crotch side is woven with the marking line of tape at the foot; then the shorts are dyed, and tape on B: Tape the woven shorts on the tape machine along the marking line of the tape at the foot. 0.02Kpa, blowing volume level 2, blowing temperature 270°C; C pressing: put the shorts on the lower pressing plate of the press machine for pressing, turn the underwear for multiple pressings to ensure that the shorts do not leak pressure, in order to ensure No leakage of pressure, each press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com