A columnar sediment gravity sampler for deep sea cableless sampling and its application

A sampler and sediment technology, applied in the field of cableless submarine sediment layer sampler and submarine sediment layer sampler, can solve the problems of ultra-deep sea sampling technology hindering deep-sea geological and life science research, etc., to reduce the risk of loss and stabilize Strong, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

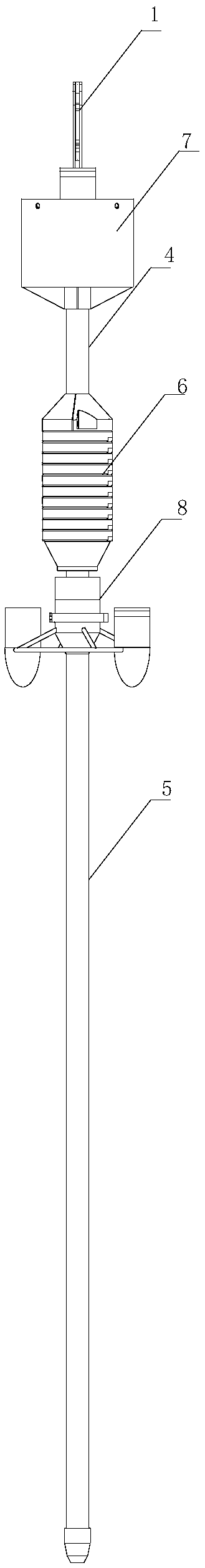

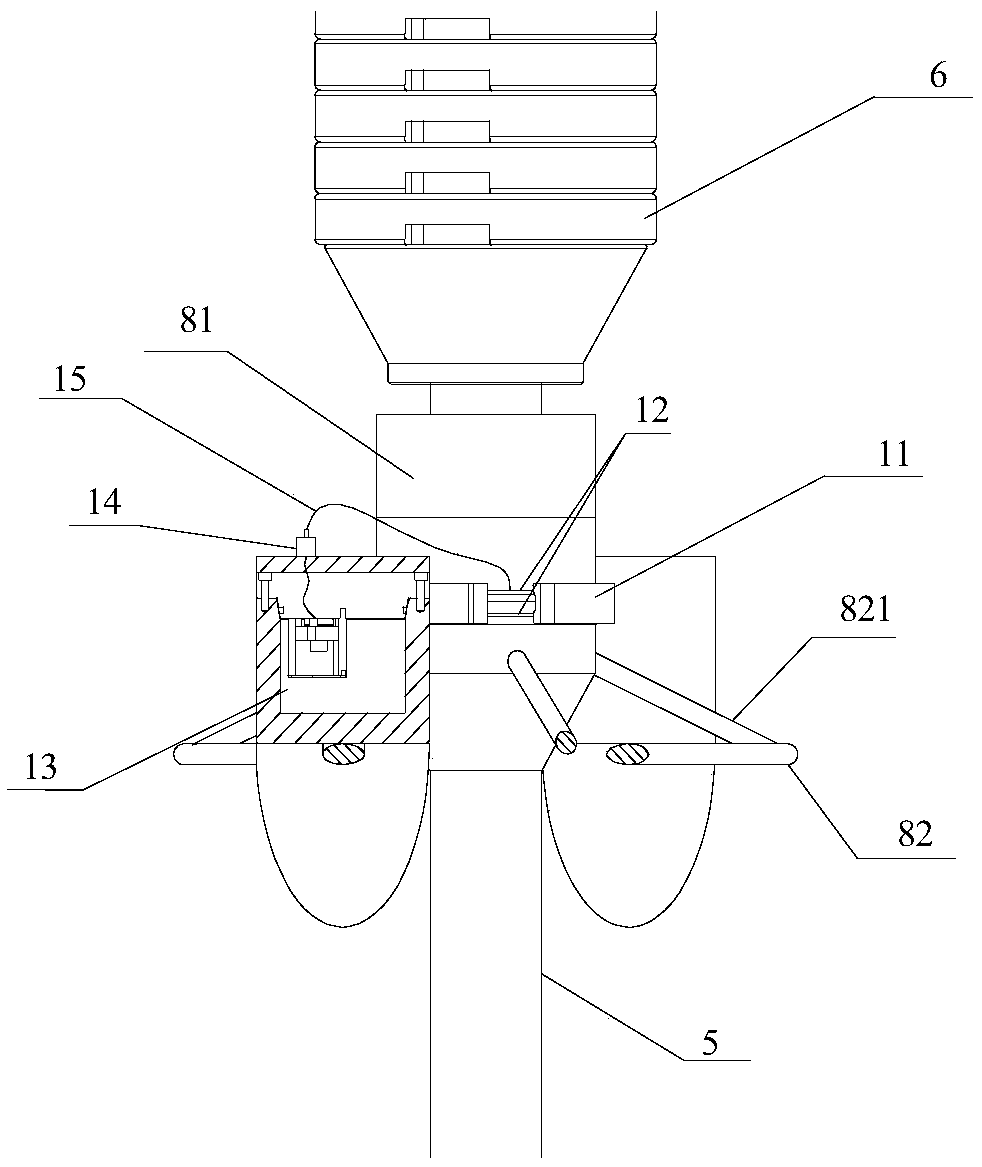

[0028] A cableless gravity sampler substantially comprising a recovery unit and a discard unit;

[0029] Such as figure 1 As shown, the recovery unit includes a hook mechanism 1 that can be connected to the floating body and a sampler inner tube 4; the bottom of the hook mechanism 1 is fixedly connected to the top of the sampler inner tube 4; the discarding unit includes a sampler outer tube 5, a counterweight 6. Stabilizing fin 7 and trigger unlocking mechanism 8; the counterweight 6 is arranged circumferentially on the upper part of the outer wall of the sampler outer tube 5; the trigger unlocking mechanism 8 is sleeved on the sampler outer tube below the counterweight 6 5 on the outer wall; the stabilizer fin 7 is sleeved on the outer wall of the sampler outer tube 5 above the counterweight 6;

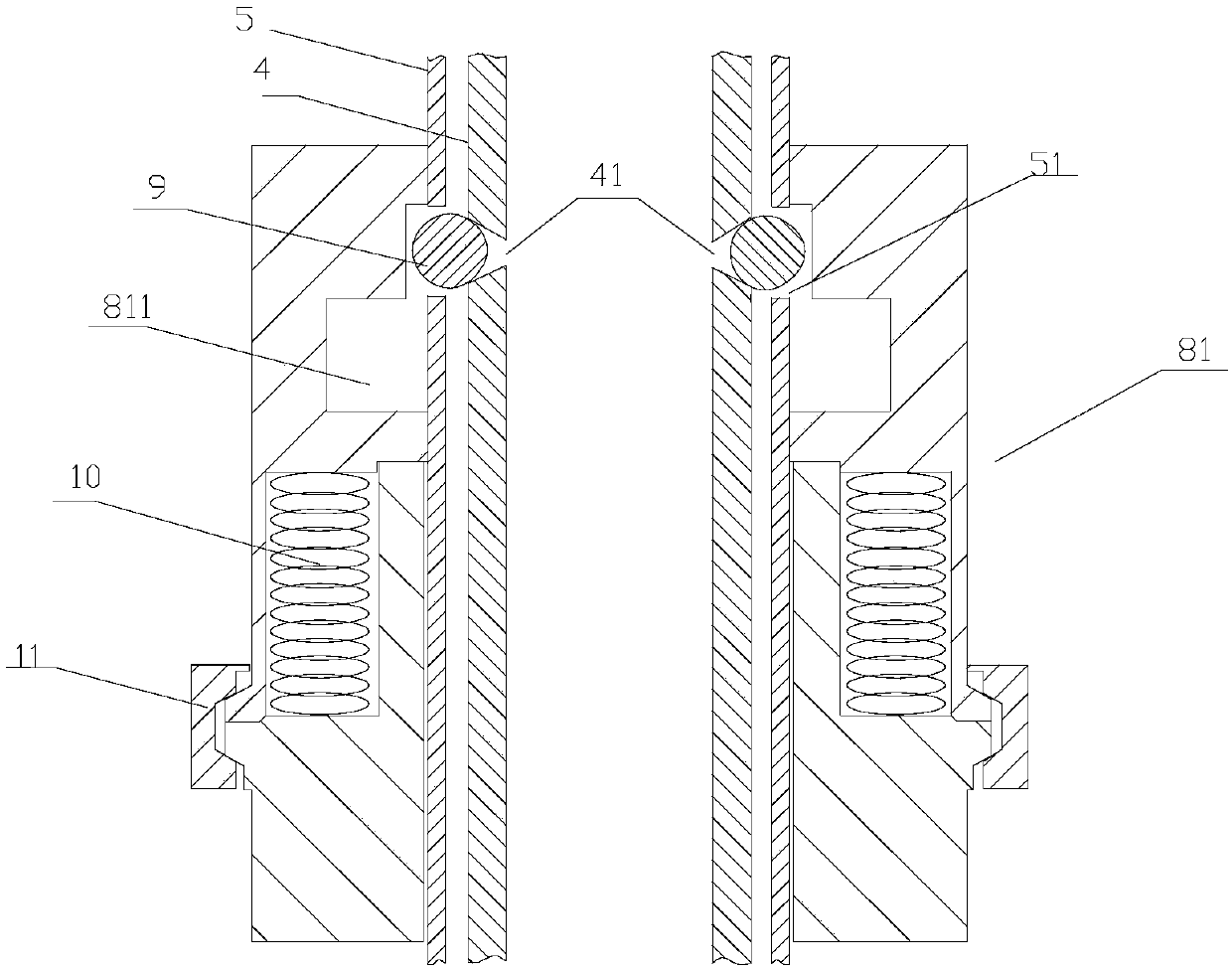

[0030] Such as figure 2 As shown, the two ends of the sampler outer tube 5 are open, the sampler inner tube 4 is sleeved in the sampler outer tube 5 and can slide axially in the ...

Embodiment 2

[0034] A cableless gravity sampler substantially comprising a recovery unit and a discard unit;

[0035] Such as figure 1 As shown, the recovery unit includes a hook mechanism 1 that can be connected to the floating body and a sampler inner tube 4; the bottom of the hook mechanism 1 is fixedly connected to the top of the sampler inner tube 4; the discarding unit includes a sampler outer tube 5, a counterweight 6. Stabilizing fin 7 and trigger unlocking mechanism 8; the counterweight 6 is arranged circumferentially on the upper part of the outer wall of the sampler outer tube 5; the trigger unlocking mechanism 8 is sleeved on the sampler outer tube below the counterweight 6 5 on the outer wall; the stabilizer fin 7 is sleeved on the outer wall of the sampler outer tube 5 above the counterweight 6;

[0036] Such as figure 2 As shown, the two ends of the sampler outer tube 5 are open, the sampler inner tube 4 is sleeved in the sampler outer tube 5 and can slide axially in the ...

Embodiment 3

[0039] A kind of cableless gravity sampler, its overall structure is identical with embodiment 1, difference is, as Figure 6 As shown, the hook mechanism 1 is composed of a release hook, an electronic timing bin 102, a watertight socket 103, a watertight cable 104 and a fusible cable 105; the release hook includes a fixed piece 1011 and a rotating piece 1012, and the described The top of the sampling inner tube 4 is fixedly connected to the bottom of the electronic timing bin 102, and the top of the electronic timing bin 102 is fixedly connected to the bottom of the fixed piece 1011; one end of the rotating piece 1012 is hinged on the top of the fixed piece 1011, and the other end can be The hinge point is that the shaft rotates to open the hook; the hook mechanism 1 is also provided with a blocking lever 1013 that can prevent the opening of the rotating piece; The hook cannot be turned and opened; the electronic timing compartment 102 is provided with a mechanical timing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com