A reinforced concrete column with a core column and replaceable parts at the failure site

A reinforced concrete column and reinforced concrete technology, applied in columns, pillars, piers and other directions, can solve the problems of low bearing reliability and difficult repair, and achieve the effects of reducing repair work, delaying the rate of stiffness degradation, and improving energy dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

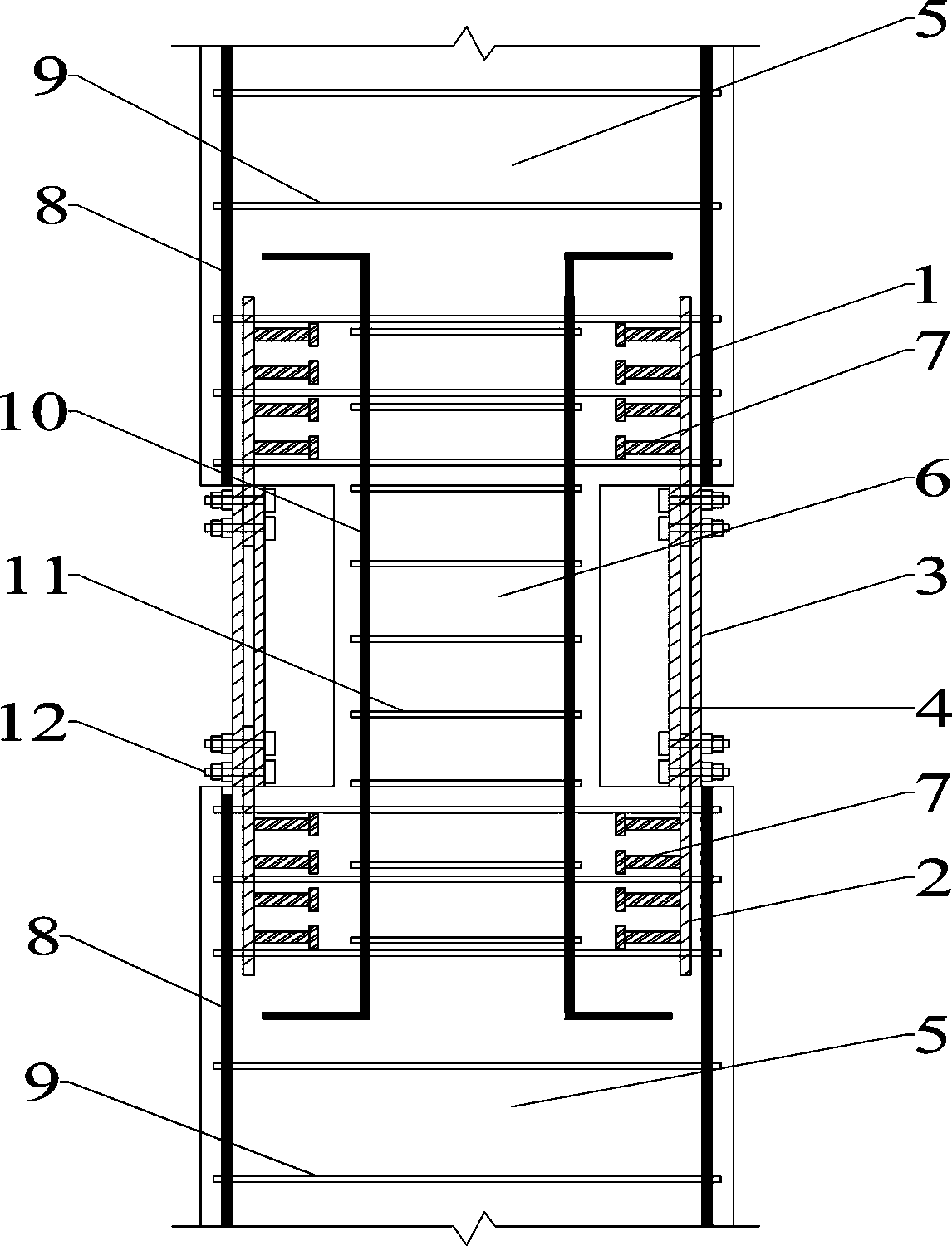

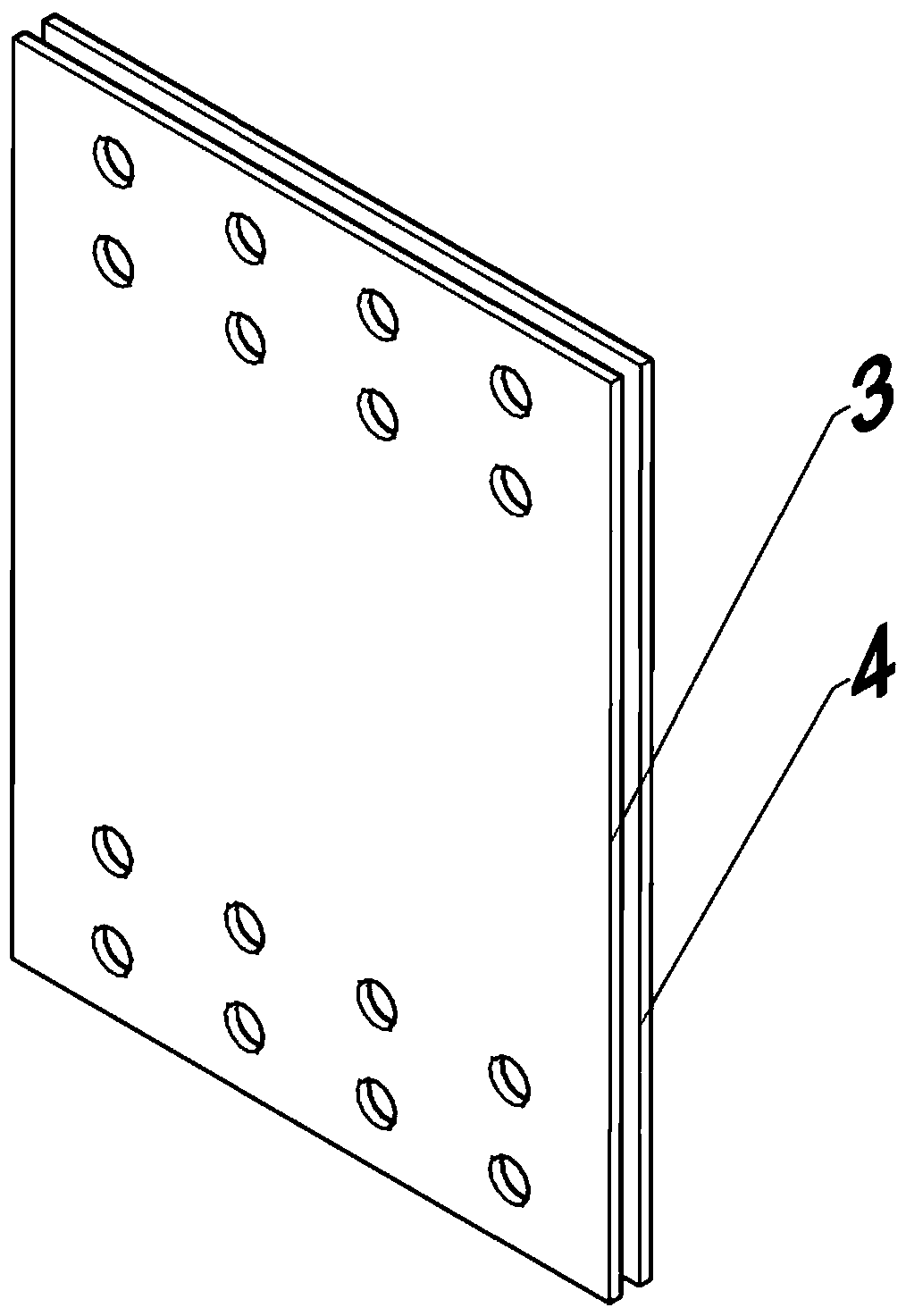

[0043] refer to figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 8 , Figure 10 , a reinforced concrete column with a core column and replaceable parts arranged at the failure position, including a reinforced concrete column body 5, and at least one section of a reinforced concrete core column 6, both ends of the reinforced concrete core column 6 are fixed to the reinforced concrete column body 5 Even, the cross-sectional dimension of the reinforced concrete core column 6 is smaller than the cross-sectional dimension of the reinforced concrete column body 5;

[0044] The reinforced concrete column also includes at least one pre-embedded steel pipe group and at least one replaceable component group. The number of pre-embedded steel pipe groups and the number of replaceable component groups are the same as the number of sections of the reinforced concrete core column. Each section of the reinforced concrete core column Corresponding to a pre-embedded steel pipe group ...

Embodiment 2

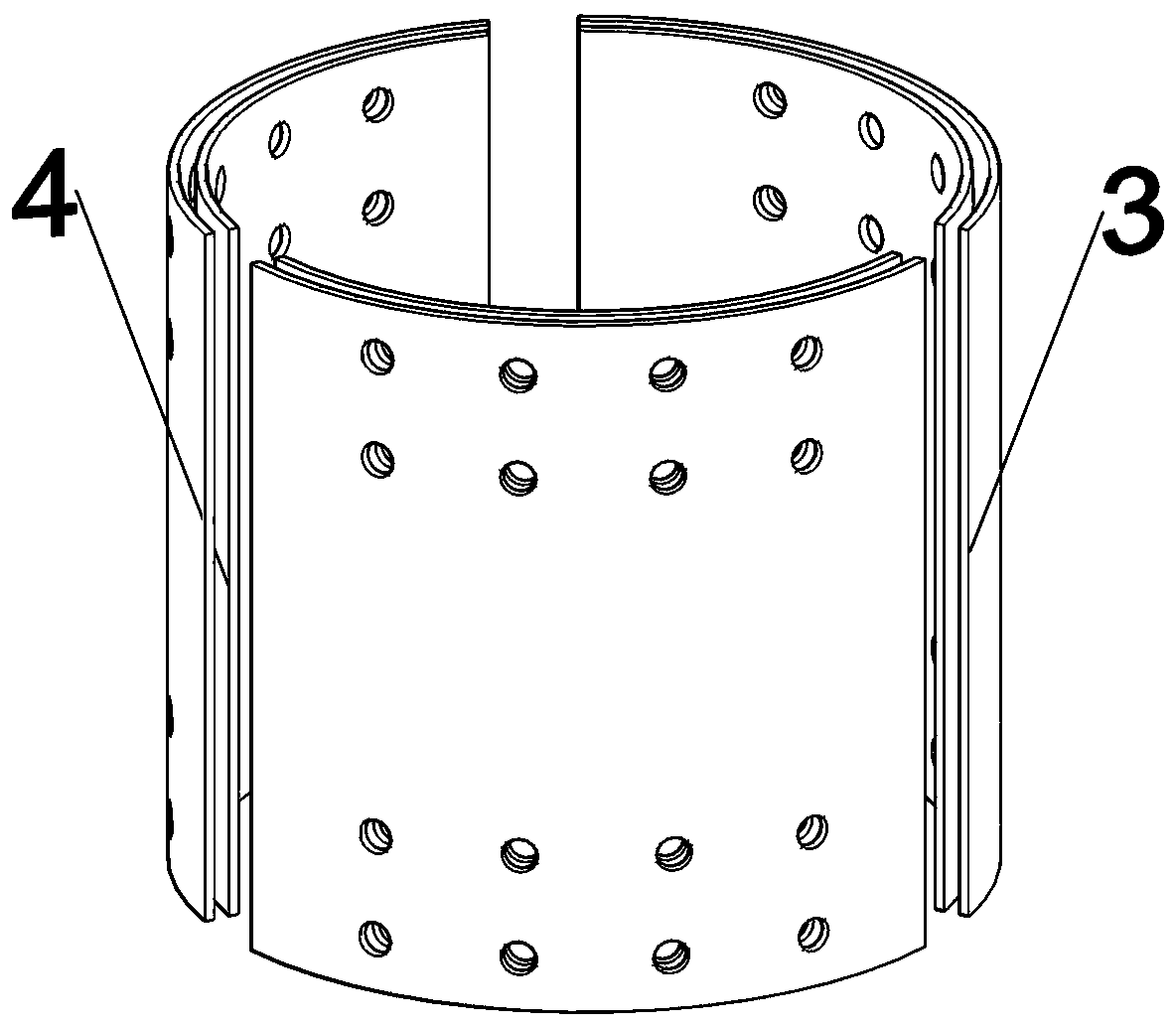

[0062] refer to image 3 , Figure 5 , Figure 7 , Figure 9 and Figure 11 , in this embodiment, the pre-embedded steel pipe is a hollow steel pipe with a circular cross section.

[0063] The cross-sectional shape of the embedded steel pipe is circular, and each replaceable part group may include two pairs of replaceable parts, or more than three pairs of replaceable parts. In this embodiment, the number of replaceable component groups is three pairs (see image 3 ). The guard plate is a curved guard plate, that is, the guard plate used as the inner replaceable part 4 and the outer replaceable part 3 is a curved guard plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com