PK prestressed concrete composite slab lifting appliance and lifting method adopting same

A hoisting method and concrete technology, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of low hoisting efficiency, large hoisting body volume, and high production cost, and achieve low production cost, stable hoisting process, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

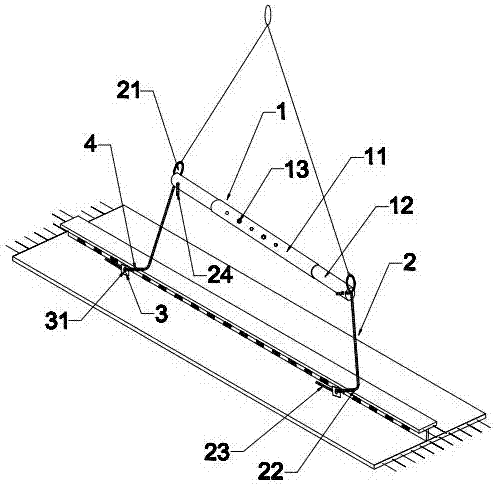

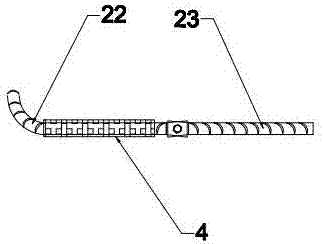

[0021] The PK prestressed concrete laminated slab spreader that present embodiment provides, as figure 1 As shown, it includes a telescopic support tube 1, two hooks 2 respectively installed at the left and right ends of the telescopic support tube 1, and two fixing cards 3 for fixing the bending portion 22 of the hook; one end of the hook 2 A suspension ring 21 is provided, and the other end is bent outward to form a hook bending part 22, and the upper end of the suspension hook 2 is detachably connected to the telescopic support tube 1; The through hole 31 of the hook bending part 22 is set, and the through hole 31 is close to its edge. When installing, the through hole 31 is close to the bottom plate of the PK board; a flexible protective cover 4 is set on the hook bending part 22 . The telescopic support pipe 1 in this embodiment is made of steel pipes, and the hook 2 is made of steel bars.

[0022] Further, in order to increase the stability of the connection between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com