Hand-cranking rotary mechanical locking overturning table

A technology of mechanical locking and hand rotation, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unsafety, high labor intensity of turning over, low efficiency of cantilever crane turning welding, etc., and achieves reduction Labor intensity, compact structure, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

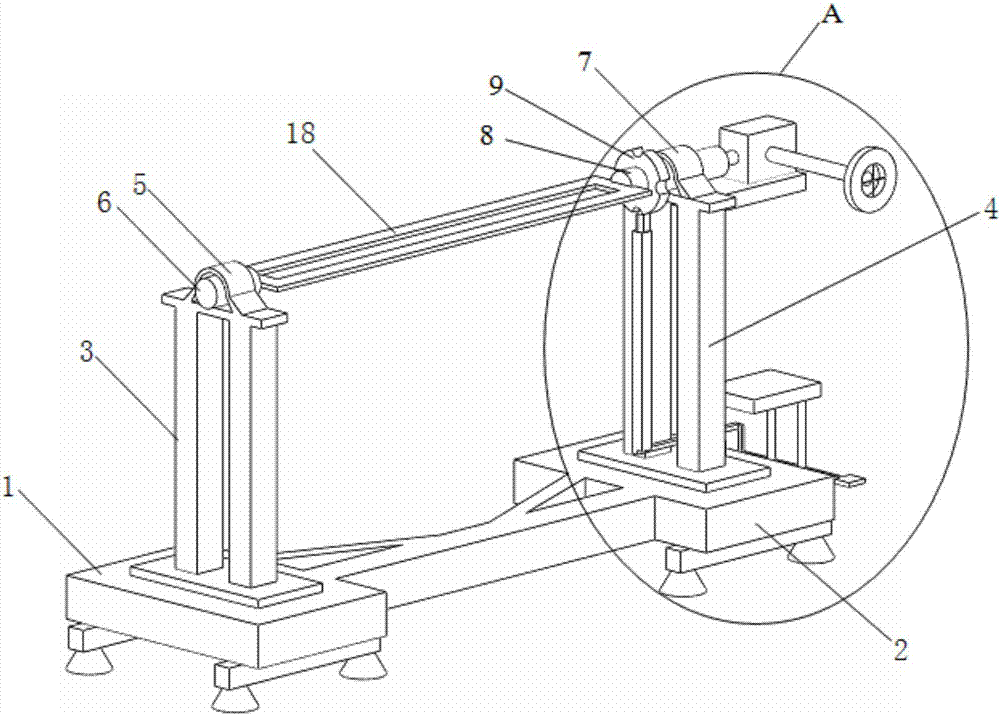

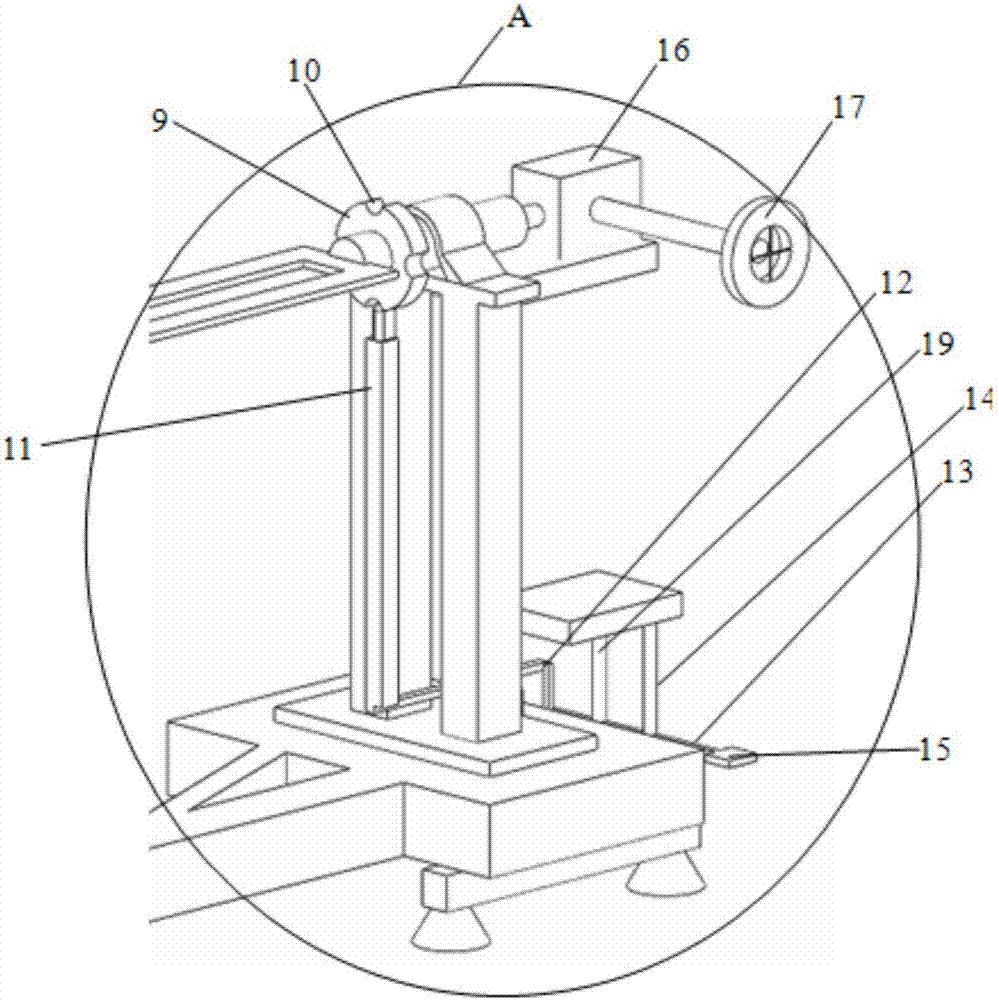

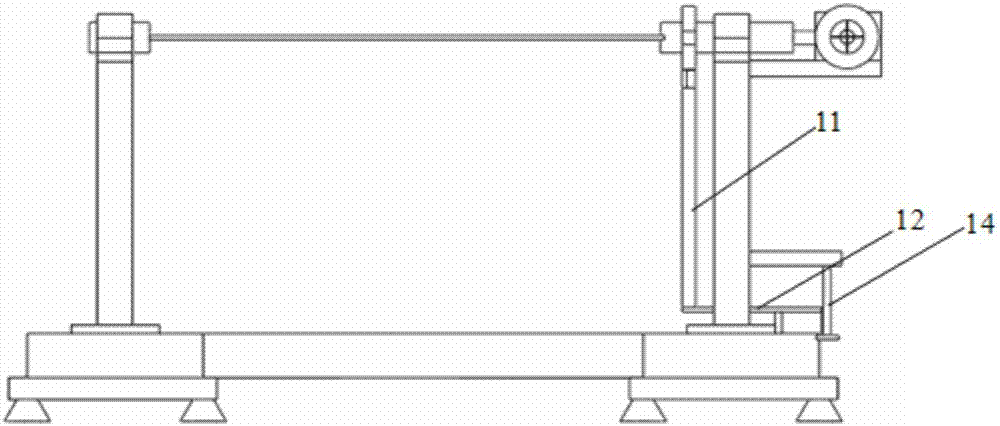

[0014] See attached Figure 1-5 As shown, a hand-operated rotating mechanical locking and turning platform includes a first base 1 and a second base 2 installed symmetrically on the left and right, and first fixing columns 3 are respectively arranged on the first base 1 and the second base 2 and the second fixed column 4, the top of the first fixed column 3 is provided with a first bearing 5, and what is connected to the first bearing 5 is a first rotating shaft 6; at the top of the second fixed column 4 A second bearing 7 is provided, and what is connected to the second bearing 7 is a second rotating shaft 8. A locking disk 9 is mounted on the second rotating shaft 8, and a locking disk 9 is provided on the locking disk 9. hole 10, and the locking hole 10 is matched with the locking pin 11, the locking pin 11 is fixed on the first connecting rod 12, and the second connecting rod is connected with the first connecting rod 12 13. The second connecting rod 13 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com