Novel solid material dissolving and extracting device

A technology of solid material and extraction device, applied in the direction of solid solvent extraction, solvent extraction, dissolution, etc., can solve the problems of extraction uniformity and difficulty in discharging, and achieve the effect of less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Below is the combination Figure 1 to Figure 6 The present invention will be described in detail.

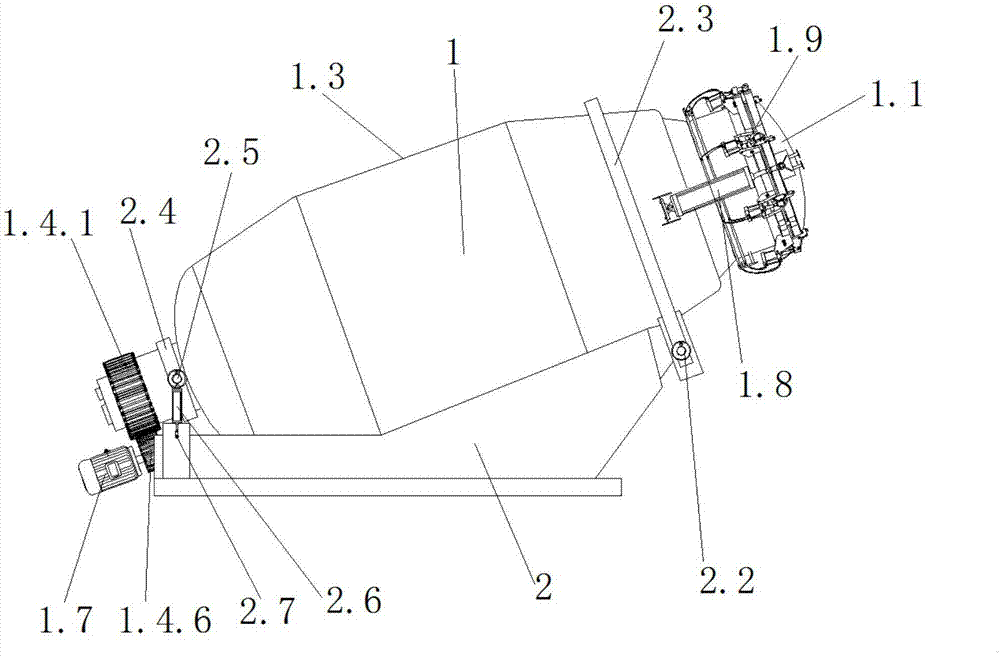

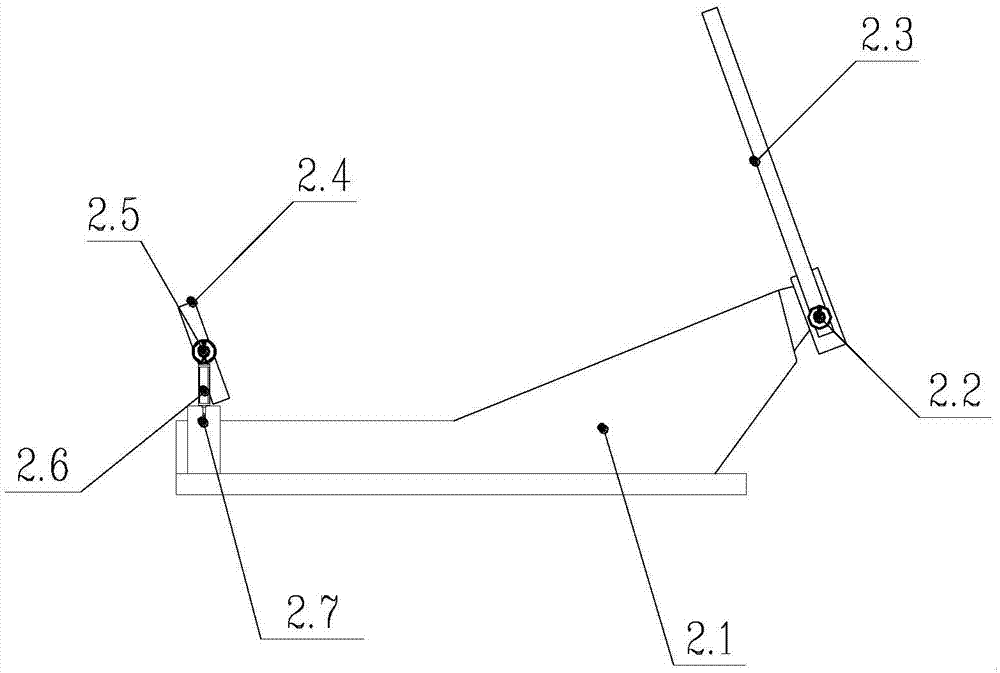

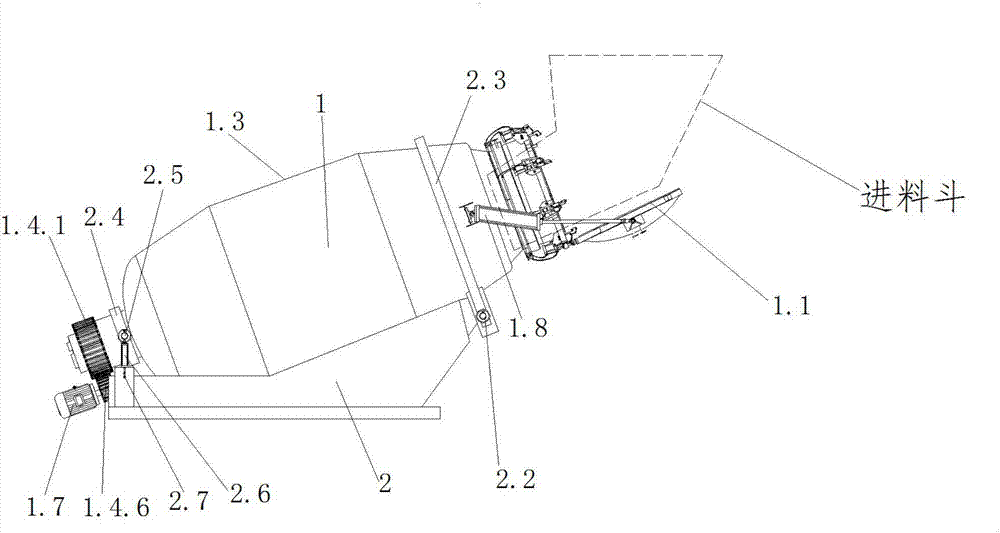

[0045] Such as figure 1 , 5 As shown, a novel solid material dissolution extraction device includes an extraction tank 1 and an extraction tank support 2, and the extraction tank support 2 can control the lifting or lowering of the tail of the extraction tank 1 when the extraction tank 1 is fed or discharged. The extraction tank 1 rotates during the extraction process, and the power device that provides power for the rotation of the extraction tank 1 is located at the tail of the extraction tank 1; the extraction tank 1 includes a tank cover 1.1, a tank body 1.2, a tank cover opening cylinder 1.8, a tank Cover clamp 1.9, the tank cover opening cylinder 1.8 is movably connected with the tank body 1.2 and the tank cover 1.1, the edge of the tank cover 1.1 is movably connected with the tank body 1.2, and the tank cover clip 1.9 can be used to lock the The tank body 1.2 is...

Embodiment 2

[0055] Below is the combination Figure 7 to Figure 8 The present invention will be described in detail.

[0056] Such as Figure 7 As shown, a novel solid material dissolution extraction device includes an extraction tank 1 and an extraction tank support 2, and the extraction tank support 2 can control the lifting or lowering of the tail of the extraction tank 1 when the extraction tank 1 is fed or discharged. The extraction tank 1 rotates during the extraction process, and the power device that provides power for the rotation of the extraction tank 1 is located on the side wall of the extraction tank 1; the extraction tank 1 includes a tank cover 1.1, a tank body 1.2, a tank cover opening cylinder 1.8, The can lid clip 1.9, the can lid opening cylinder 1.8 is movably connected with the can body 1.2 and the can lid 1.1, the edge of the can lid 1.1 is movably connected with the can body 1.2, and the can lid clip 1.9 can be used to lock the The tank body 1.2 is sealed; the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com