Three-barrel compound scraper planter

A planter and compound technology, applied in the application field of agricultural seeding technology, can solve the problems of high labor consumption, affecting seed growth, and large physical energy consumption, and achieve the effects of reducing labor intensity, good practicability, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

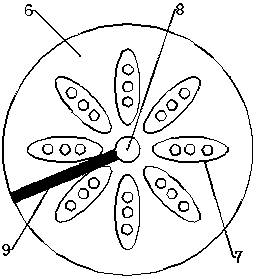

[0022] As shown in the drawings, a three-barrel compound scraper planter includes a base 1, wheels 2, a first mounting frame 3, a seed storage bucket 4, a delivery pipe 5, a rotating disc 6, a seeding tank 7, and a central shaft 8. Baffle plate 9, first bevel gear 10, second bevel gear 11, first connecting shaft 12, first motor 13, fixed frame 14, seeding hole 15, inoculation bucket 16, planting bucket 17, soil divider 18. The first connecting seat 19, the first push rod 20, the first hydraulic cylinder 21, the second mounting frame 22, the loosening bucket 26, the loosening tooth 27, the driven wheel 28, the belt 29, the driving wheel 30, the second connection Shaft 31, second motor 32, laminating barrel 33, ring knife 34, second connecting seat 25, second push rod 24, second hydraulic cylinder 23, wheels 2 are installed on the bottom of the base 1, and the base 1 The first installation frame 3 is welded on the top, and the top of the first installation frame 3 is fixed with ...

Embodiment 2

[0025] As shown in the drawings, a three-barrel compound scraper planter includes a base 1, wheels 2, a first mounting frame 3, a seed storage bucket 4, a delivery pipe 5, a rotating disc 6, a seeding tank 7, and a central shaft 8. Baffle plate 9, first bevel gear 10, second bevel gear 11, first connecting shaft 12, first motor 13, fixed frame 14, seeding hole 15, inoculation bucket 16, planting bucket 17, soil divider 18. The first connecting seat 19, the first push rod 20, the first hydraulic cylinder 21, the second mounting frame 22, the loosening bucket 26, the loosening tooth 27, the driven wheel 28, the belt 29, the driving wheel 30, the second connection Shaft 31, second motor 32, laminating barrel 33, ring knife 34, second connecting seat 25, second push rod 24, second hydraulic cylinder 23, wheels 2 are installed on the bottom of the base 1, and the base 1 The first installation frame 3 is welded on the top, and the top of the first installation frame 3 is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com