A disc connecting rod automatic welding machine

An automatic welding machine and connecting rod technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inaccurate ring position, high welding error rate, and inconsistent weld width, etc., to achieve Automatic operation, uniform surface radian and uniform weld width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

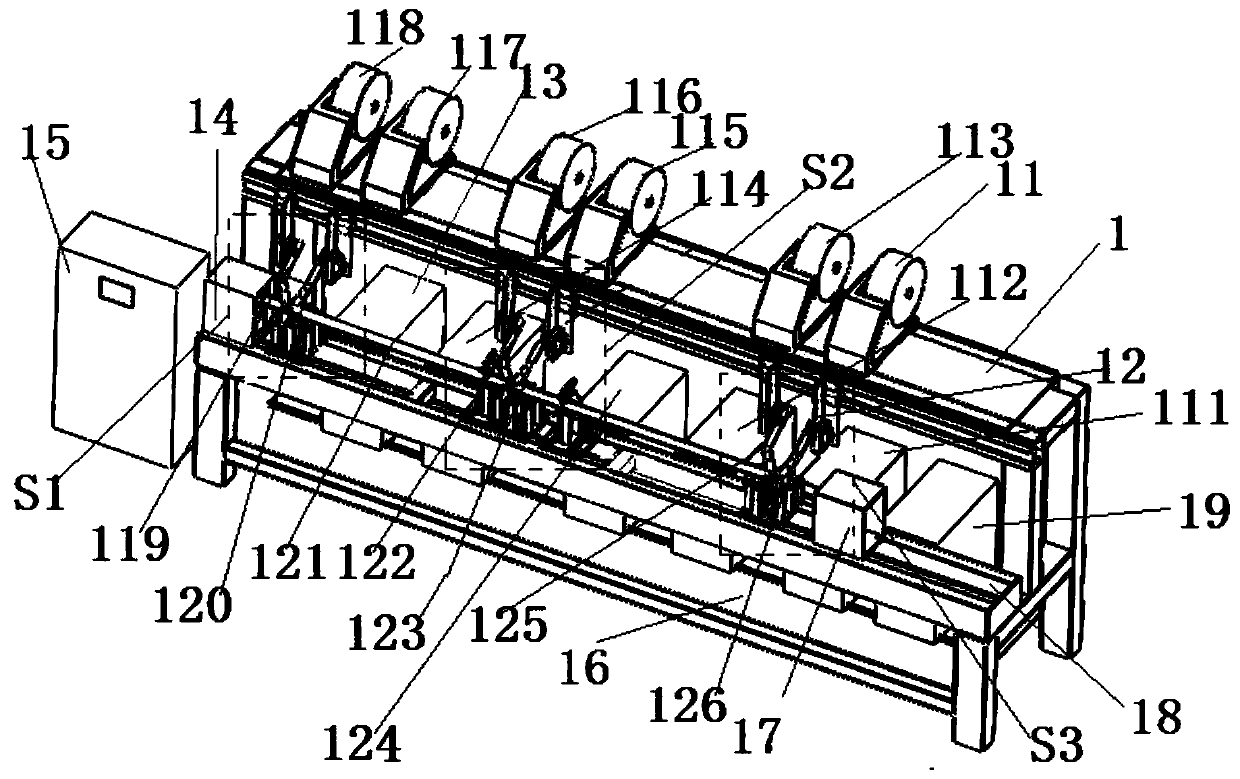

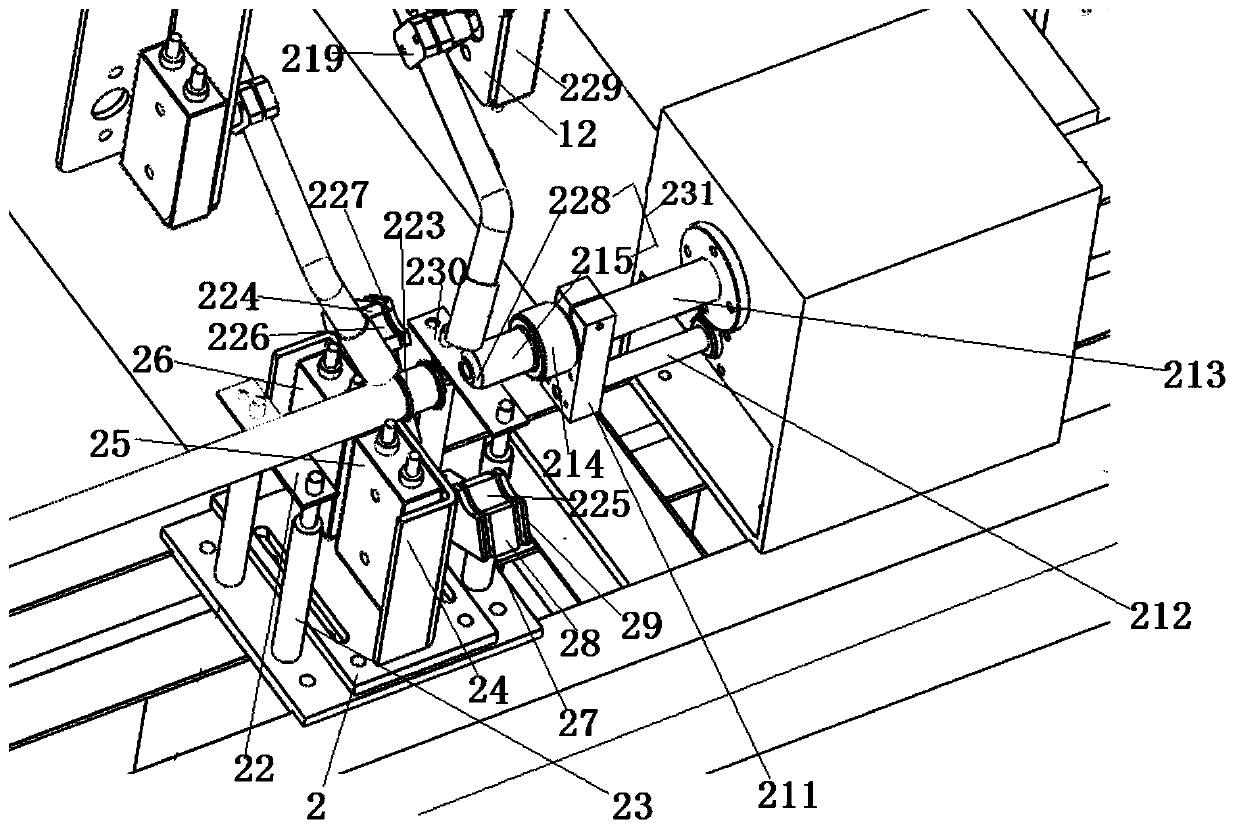

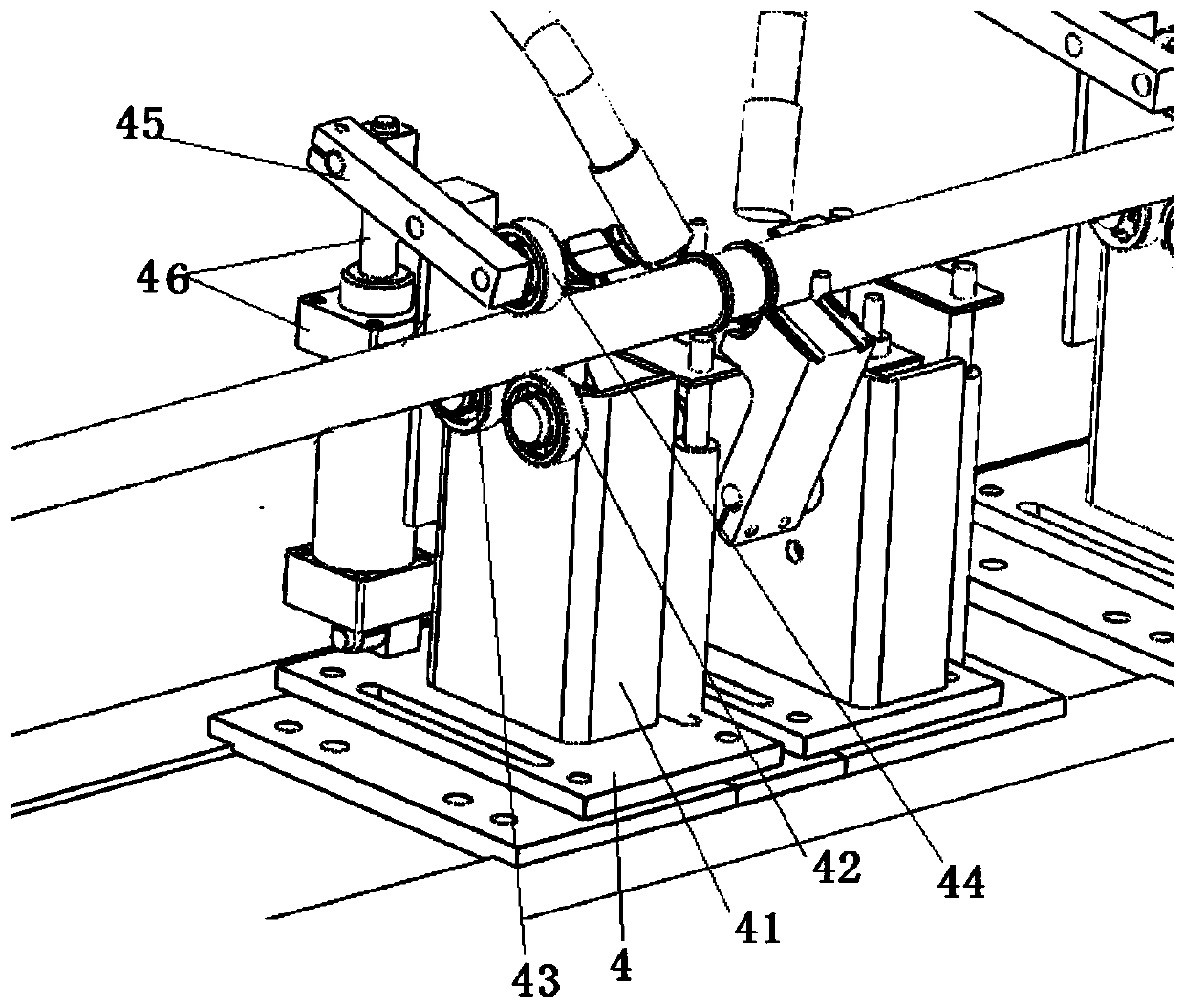

[0031] figure 1 It is the schematic diagram of the disc connecting rod automatic welding machine described in the present invention; figure 2 for figure 1 Partial enlarged schematic diagram of the area shown in S3; image 3 for figure 1 Partial enlarged schematic diagram of the area shown in S2; Figure 4 for figure 1 The local enlarged schematic diagram of the region shown in S1. like Figure 1-Figure 4 As shown, the present invention provides a disc connecting rod automatic welding machine, including a frame, a tooling clamping mechanism, a workpiece positioning and clamping mechanism, a welding torch lifting mechanism, a welding torch and a connecting rod 121, and the frame is fixed with The tooling clamping mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com