Methods and systems for an exhaust aftertreatment device

A technology of exhaust post-treatment and post-processing devices, which is applied in the direction of exhaust devices, combustion methods, noise reduction devices, etc., can solve the problems of catalyst quality impact, reduce catalyst packaging restrictions, etc., and achieve easy ignition conditions and meet ignition conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

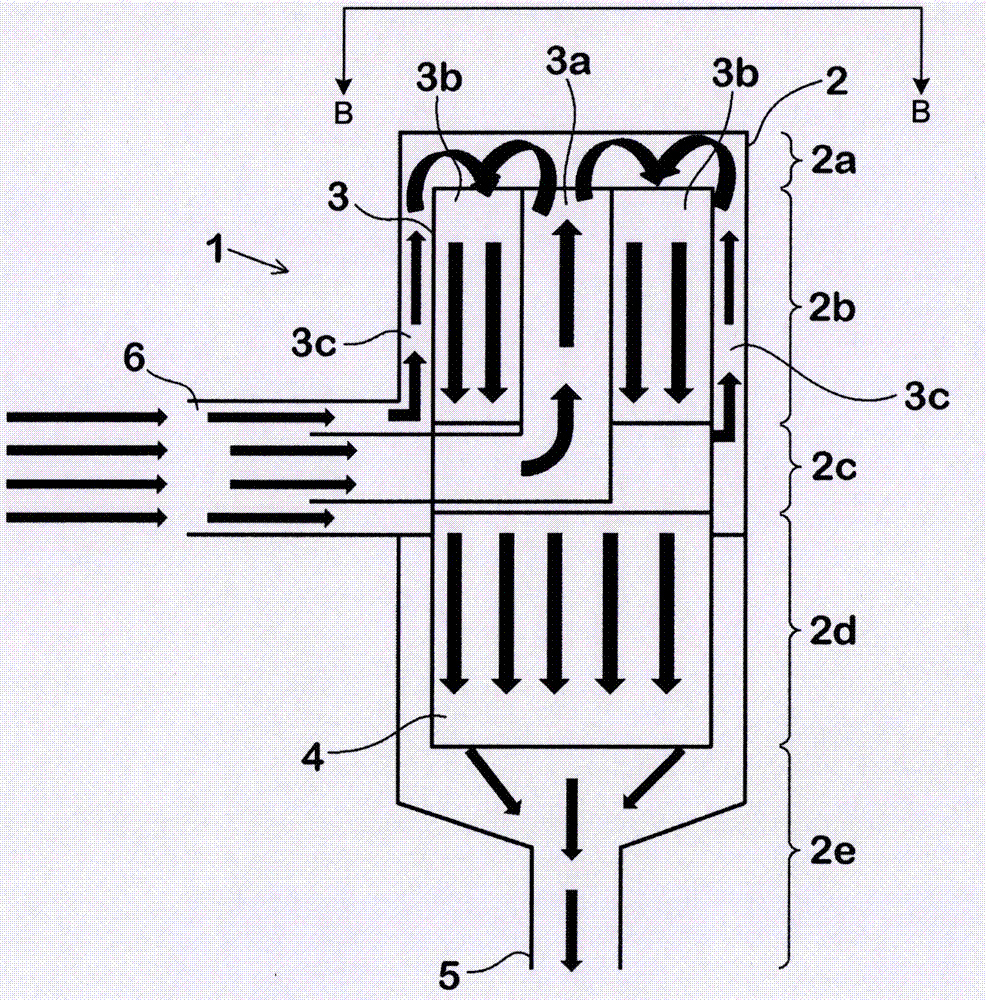

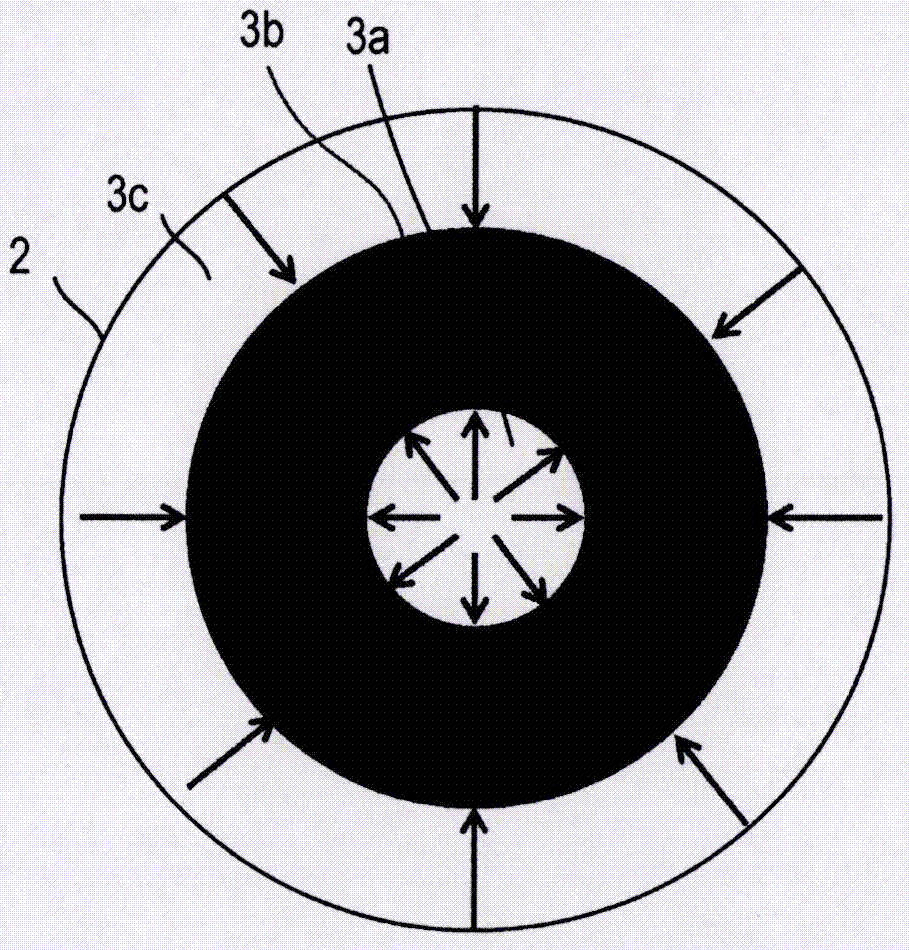

[0036] The following description relates to systems and methods for exhaust aftertreatment devices. The catalyst and particulate filter are located in the exhaust aftertreatment housing. The catalyst is a toroid with a central channel in its central opening and an outer channel between the catalyst and the aftertreatment housing. Exhaust from the exhaust outlet flows into the central and outer passages before flowing into the catalyst, such as figure 1 shown. As the exhaust gas flows through these passages in a first direction, the exhaust gas preheats the catalyst before flowing into the catalyst, as figure 2 shown. Exhaust gases flow out of the central and outer passages into a first end of the housing, while exhaust gases in a second direction may mix at the first end before flowing through the catalyst. In one example, the second direction is opposite the first direction such that the exhaust flow in the housing is generally U-shaped. By arranging the catalyst and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com