A pile foundation static load test system

A technology of static load test and pile foundation, which is applied in the test of foundation structure, foundation structure engineering, construction, etc. It can solve problems such as weight block slipping, ballast center of gravity imbalance, affecting detection accuracy, etc., and achieve easy control of ballast body balance performance, improving resource utilization, and the effect of test process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

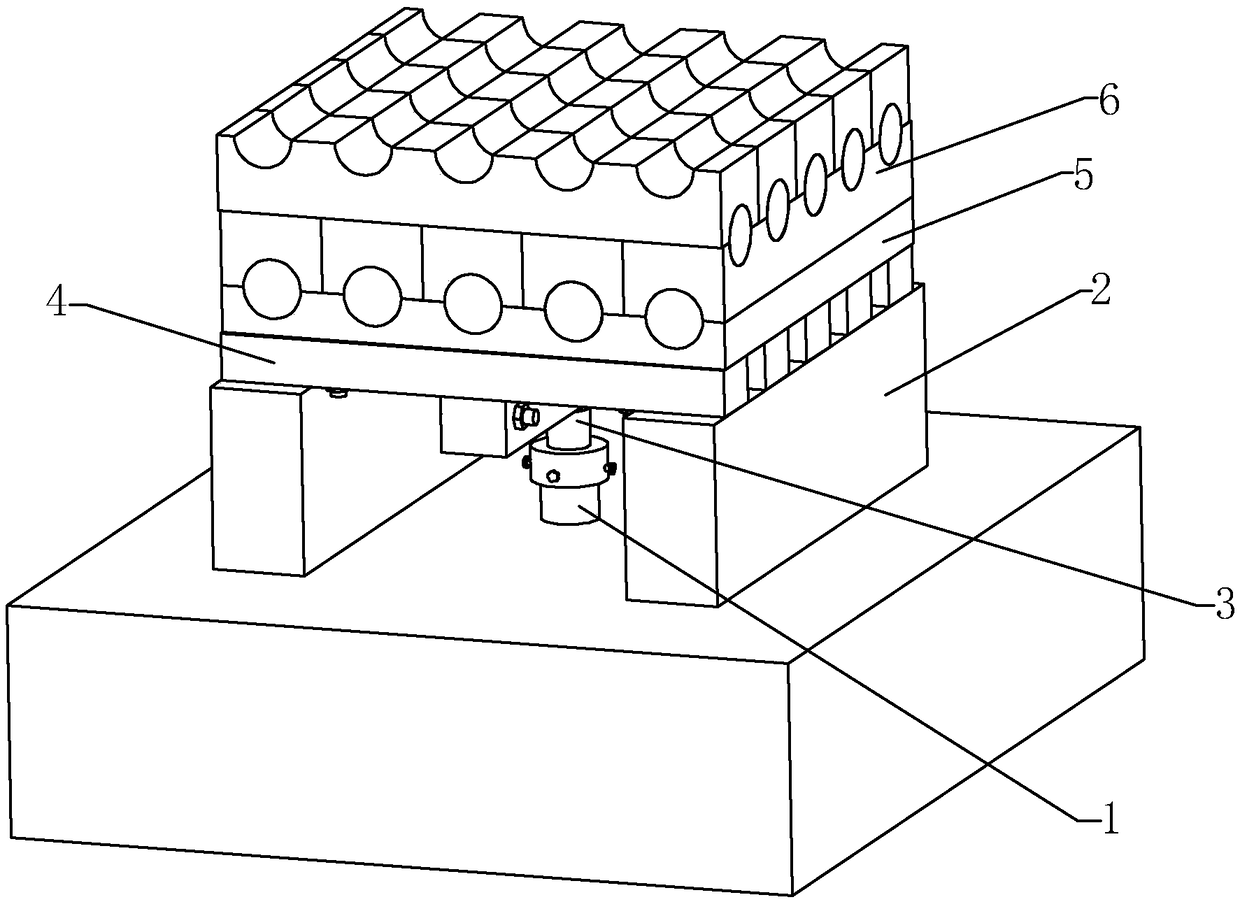

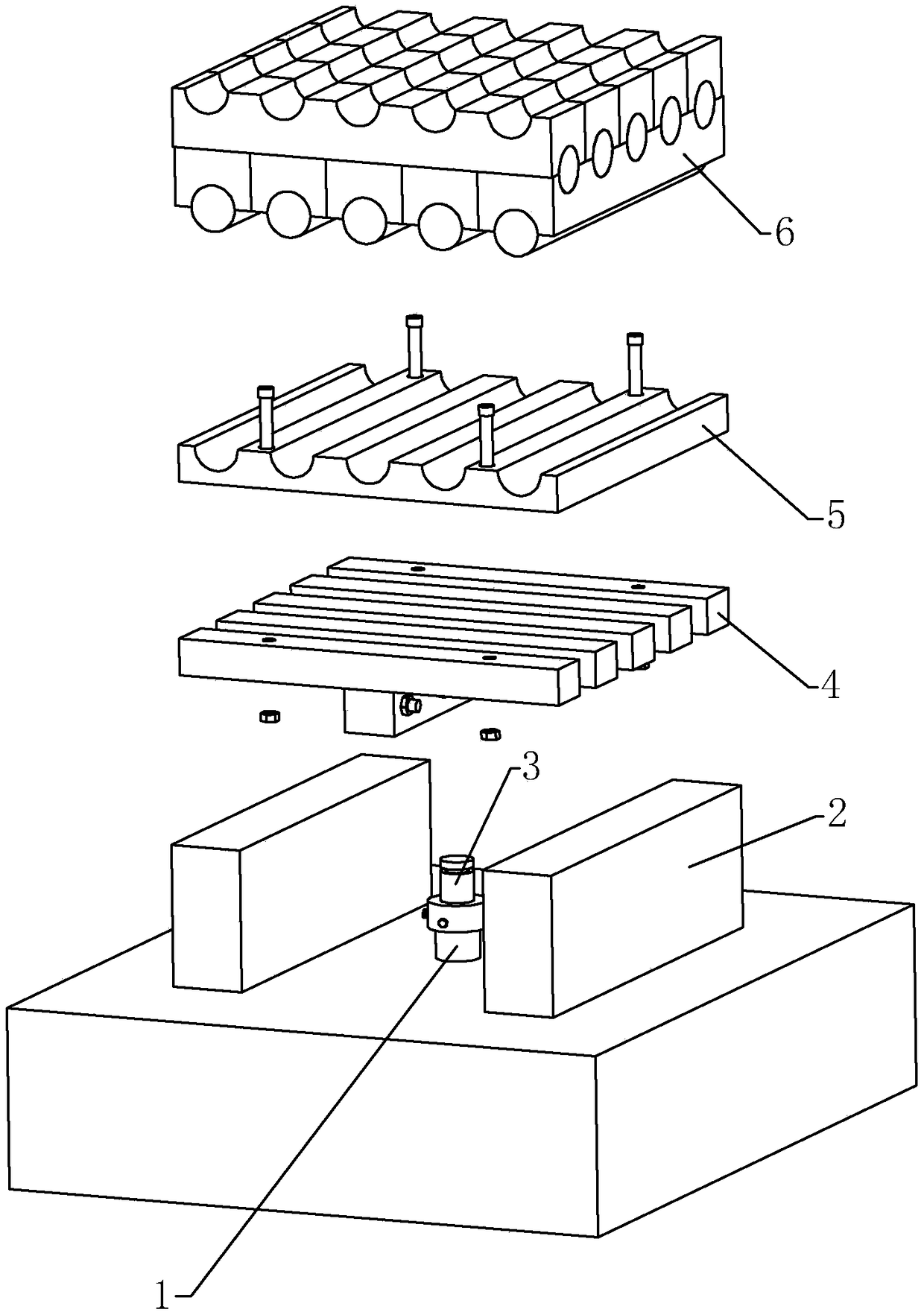

[0033] This embodiment discloses a pile foundation static load test system with surcharge method, such as figure 1 , 2 As shown, it includes a test pile 1 , a bearing wall 2 , a jack 3 , a reaction frame 4 , a bearing plate 5 and a counterweight 6 .

[0034] Such as image 3 As shown, the jack 3 is installed directly above the axis of the test pile 1, and the pile head of the test pile 1 is covered with a steel reinforcing cover 7, and combined with Figure 4 to Figure 6 , the overall shape of the reinforcement cover 7 is a cylindrical shape with a closed upper end, a positioning groove 8 is provided at the inner axis of the top wall of the reinforcement cover 7, and a positioning groove 8 is provided at the axis of the upper end surface of the test pile 1 to match the size of the positioning groove 8. The positioning round platform 9. The outer side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com