Prefabricated plate track structure applicable to circular tunnel

A technology of prefabricated slabs and tunnels, which is applied to tracks, roads, ballast layers, etc., can solve problems such as maintenance difficulties, tight boundaries, and irregular shapes of filling layers, so as to reduce the risk of water seepage, facilitate repair and maintenance, increase The effect of cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

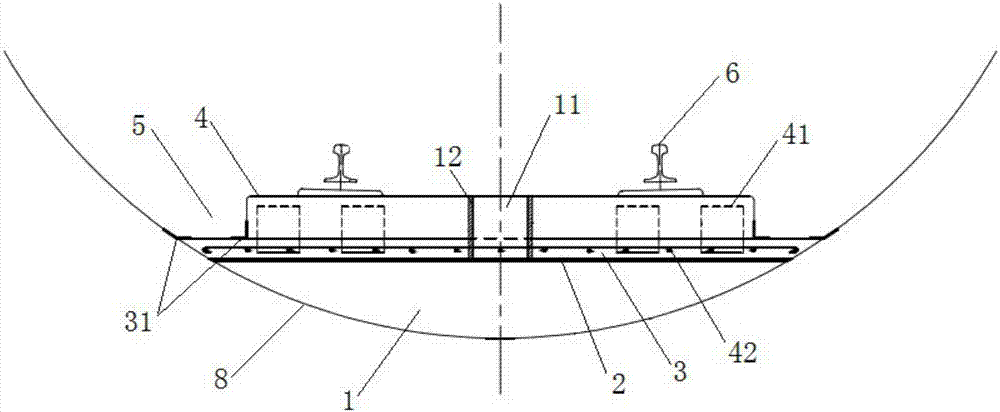

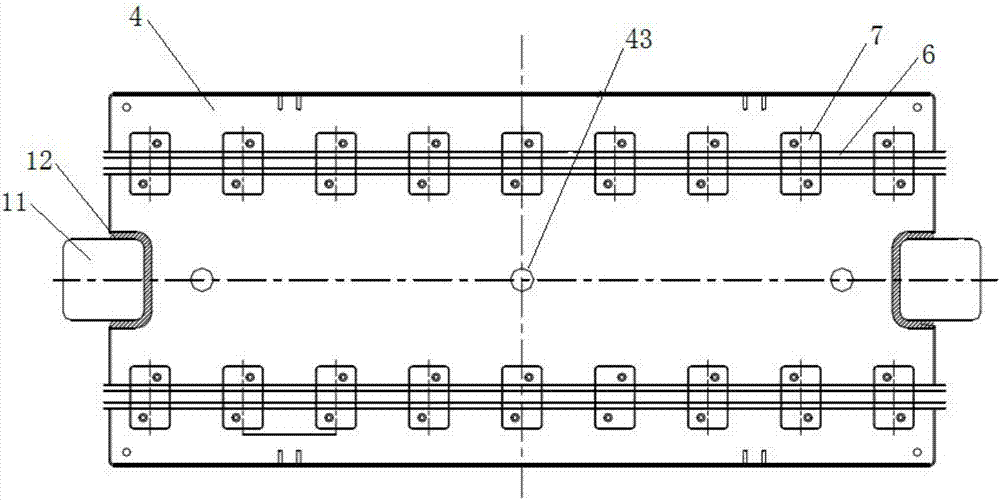

[0029] A prefabricated slab track structure applied to a circular tunnel, comprising a base 1, a geotextile 2 and a track slab 4 arranged in sequence from bottom to top. Geotextile 2 and track slab 4 adjustment layer 3. After the relative positions of base 1, geotextile 2 and track slab 4 are determined, concrete is poured to form adjustment layer 3, which is used to eliminate manufacturing errors of the base and track slab. The geotextile 2 is used to isolate the base 1 and the adjustment layer 3 to facilitate the separation of the adjustment layer 3 from the base 1. When the base 1 has quality problems, the adjustment layer 3 is lifted to facilitate the maintenance of the base 1. The bottom of track plate 4 is provided with connecting position 41, and connecting position 41 is fixedly connected with reinforcing bar mesh 42, and reinforcing bar net 42 is arranged in adjusting layer 3, makes track plate and adjusting layer 3 fixedly combined. Both sides of the track plate 4 ar...

Embodiment 2

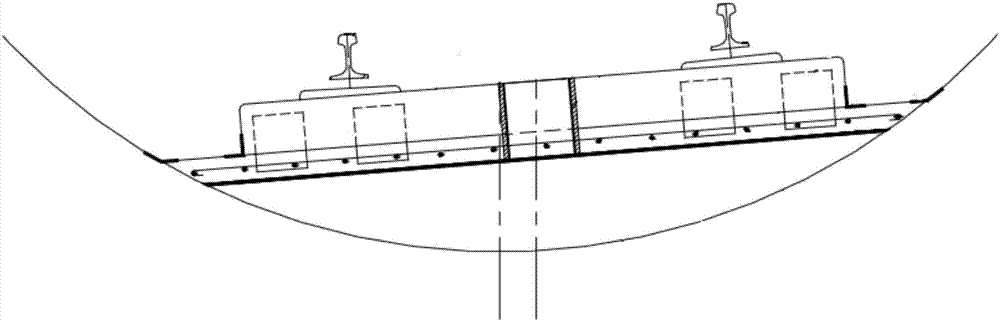

[0034] The difference between implementation 2 and embodiment 1 is that: in implementation 1, the upper part of base 1 is a horizontal plane structure, which is suitable for straight tunnels; in embodiment 2, the upper part of base 1 is an inclined plane structure, and the structure It is suitable for curved tunnels, wherein the inclination angle of the upper plane structure of the base 1 depends on the curvature of the curved tunnel and the design speed per hour of the train.

[0035] A construction method for a prefabricated slab track structure applied to a circular tunnel according to the present invention comprises the following steps:

[0036] S1: Fix the rail 6 on the upper part of the track slab 4, and fix the steel mesh 42 on the connection position 41 at the lower part of the track slab 4;

[0037] S2: Bundling the reinforcement cage of the base 1 and the limiting boss 11 and pouring the base 1 and the limiting boss 11;

[0038] S3: laying geotextile 2 on base 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com