Injection molding mold having anti-pressure-relief function

An injection mold and anti-leakage technology, which is applied in the field of molds, can solve the problems of high energy consumption, reduced service life, and failure to reach, and achieve the effects of simple device structure, improved service life, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

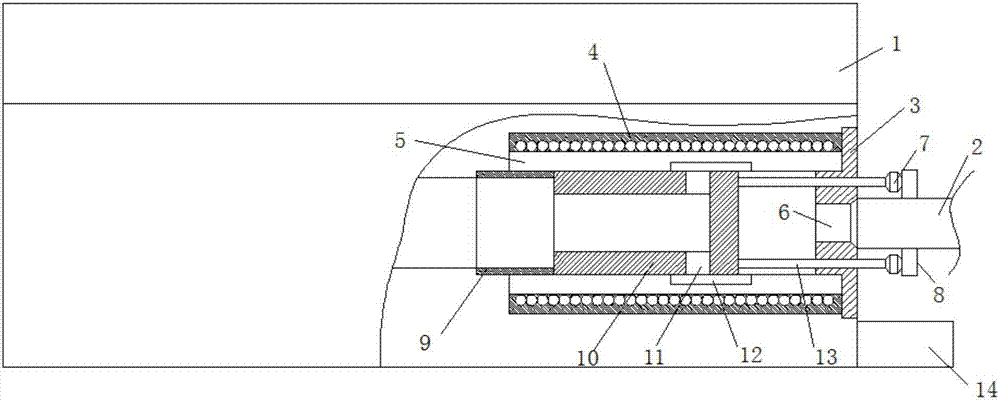

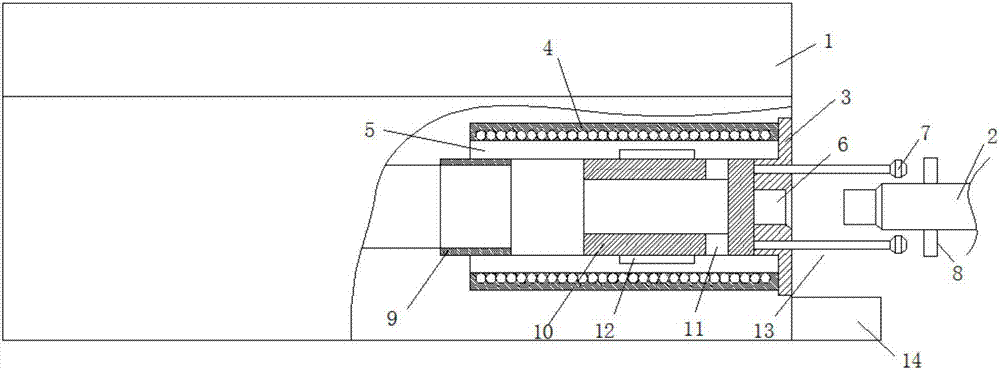

[0017] Such as Figure 1-2 As shown, an injection mold with anti-pressure relief function includes a mold main body 1 and a machine head 2, an electromagnetic chuck 8 is provided outside the injection port of the machine head 2, and a protective valve is provided inside the main channel of the mold main body 1. Pressure column 5, the outer side of the pressure holding column 5 is sleeved with the heating sleeve 4, the inside of the pressure holding column 5 is provided with an anti-pressure relief device, and the end of the pressure holding column 5 corresponding to the injection port of the machine head 2 is provided with a positioning method Lan 3, the center of the positioning flange 3 is provided with a pouring port 6 corresponding to the injection port of the machine head 2.

[0018] In this embodiment, the pressure relief device includes a one-way stem 10 and a push-pull rod 13, the one-way stem 10 is located inside the pressure-holding column 5, and the one-way stem 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com