Overrun clutch with delay function

A technology of overrunning clutches and functions, applied in clutches, one-way clutches, mechanical equipment, etc., can solve problems such as cost increase and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

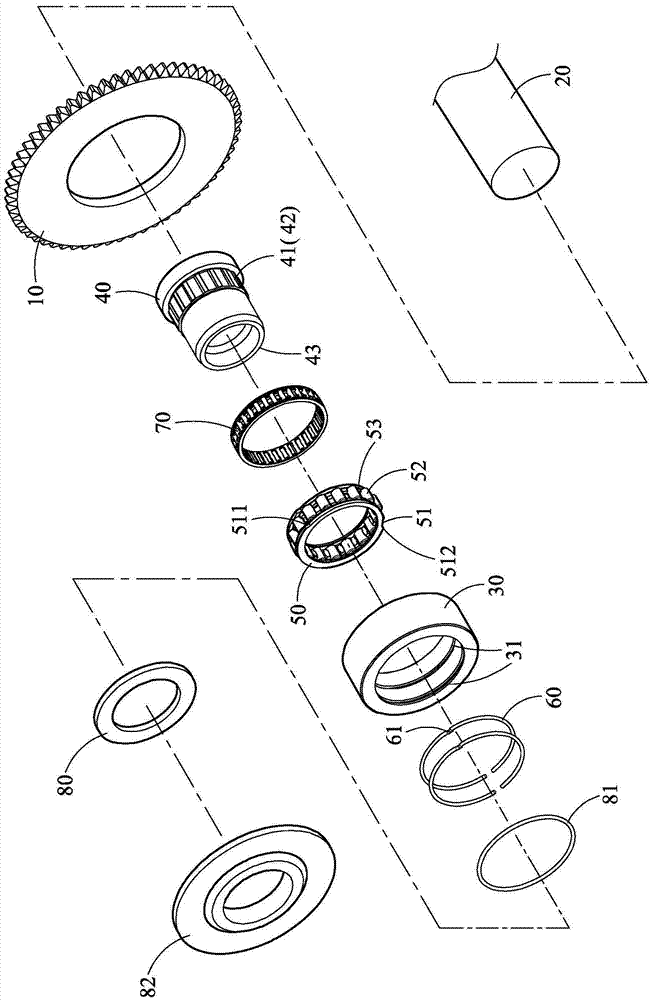

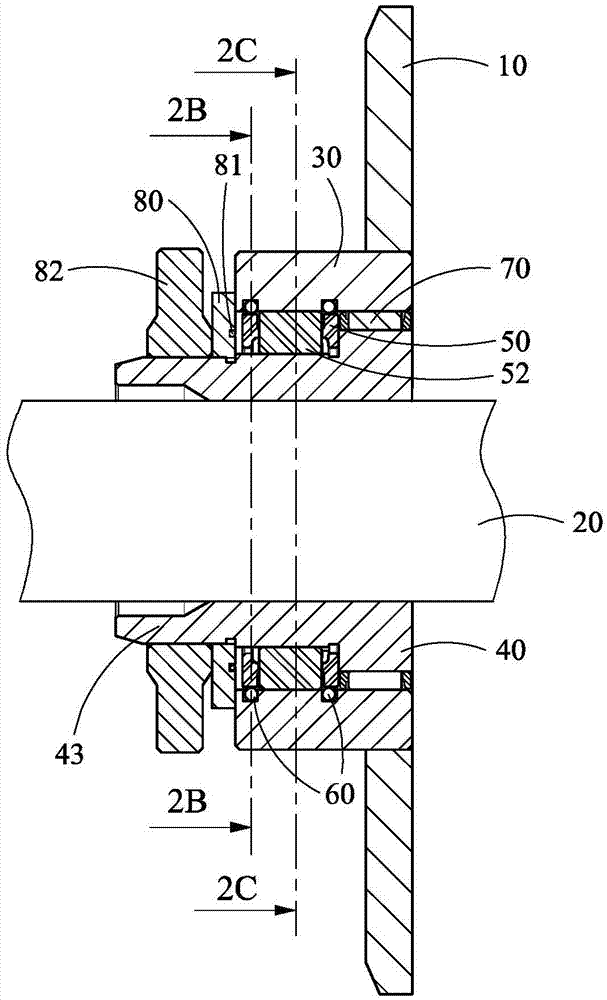

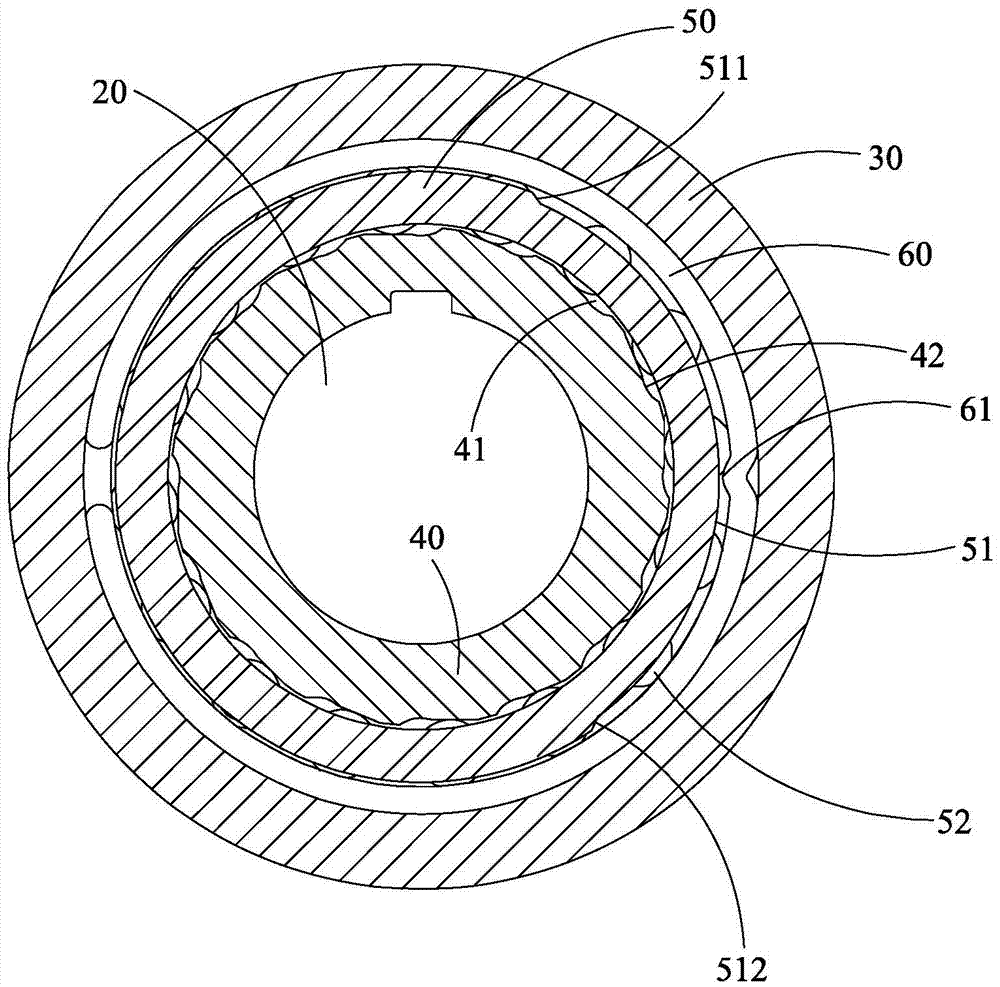

[0022] see figure 1 , Figure 2A-Figure 2D Shown, the present invention is a kind of overrunning clutch with delay function, is used for linking a driving gear 10 and a crankshaft 20, and it comprises a first collar 30, a second collar 40, a roller cage 50 and At least one control ring 60. Wherein the first collar 30 is connected with the starter gear 10, the second collar 40 is connected with the crankshaft 20, and the first collar 30 and the second collar 40 can rotate relatively coaxially. 40 has a plurality of recesses 41 each with an inclined bottom surface 42, and the first collar 30 is sleeved on the outside of the second collar 40, and the first collar 30 and the second collar 40 can be At least one set of roller bearings 70 is provided to increase the stability of rotation.

[0023] The roller cage 50 is disposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com