Restoration method for coal mine giant collapse pits

A repair method and technology for subsidence pits, which are applied in the field of repairing giant subsidence pits in coal mines, can solve problems such as lack of systematic understanding of backfill materials, and achieve the effects of ensuring backfill effect, repair effect, and governance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

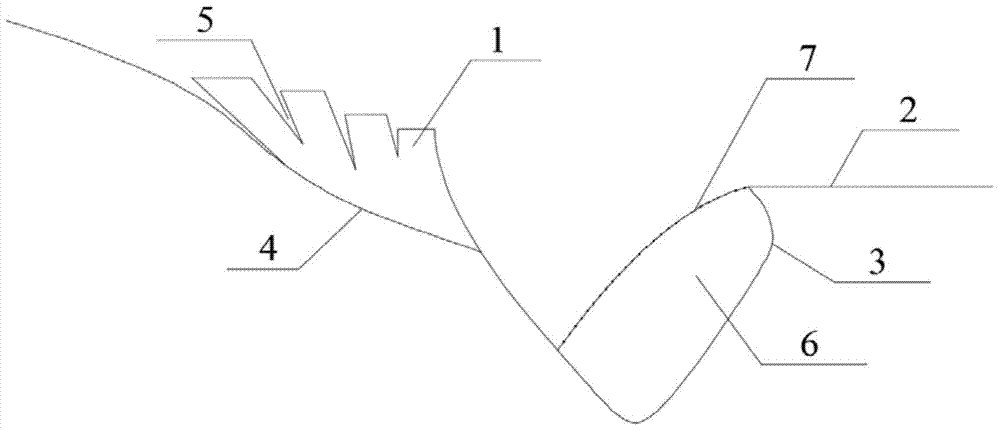

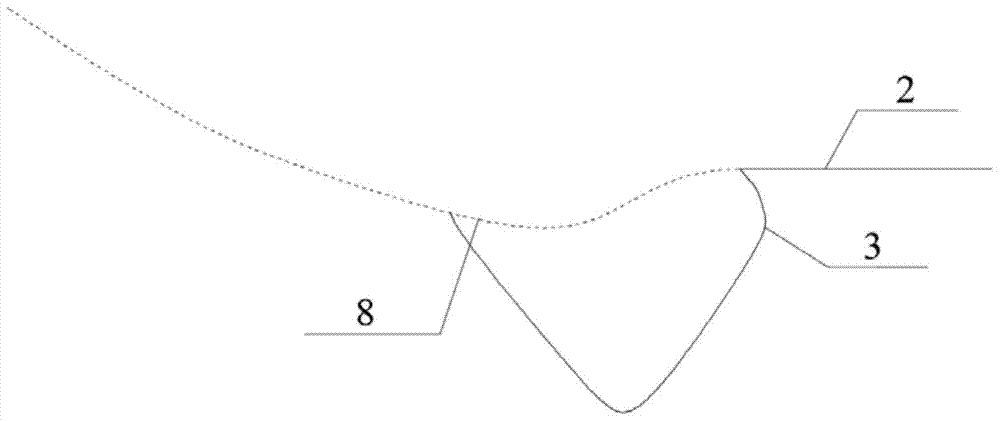

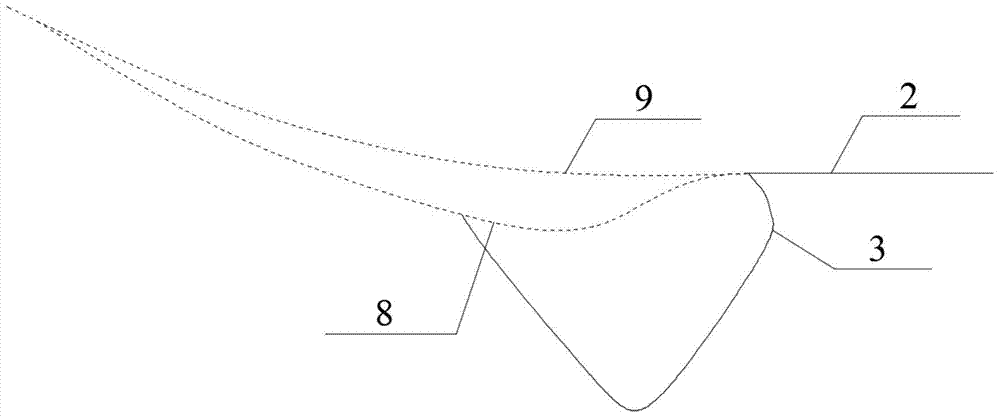

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0034] As an embodiment of the present invention, take the restoration project of a huge subsidence pit on the surface in the coal mining subsidence area in the south of Dayan No. 1 Mine as an example. Dayan No. 1 Mine (hereinafter referred to as "No. 1 Mine") is located in the Ewenki Autonomous Banner in the northeast of Inner Mongolia, and belongs to the cold temperate continental semi-arid climate. The coal-bearing strata of this mine are the Yimin Formation and the lower Damoguaihe Formation of the Mesozoic lower Cretaceous system. The main mining coal seam is buried at a depth of 70-290m, and the roof lithology is fine sandstone and siltstone. The current mining method of the coal mine is mechanized fully mechanized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com