Round wood rotary cutting, drying, planishing and panel stacking automatic production device

A production device and round log technology, which is applied in the field of automatic production device for round log rotary cutting, drying, flattening and stacking, can solve problems such as difficulty in harvesting and consumption of physical strength, and achieve the goal of overcoming the impact of weather, reducing physical output, and liberating labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

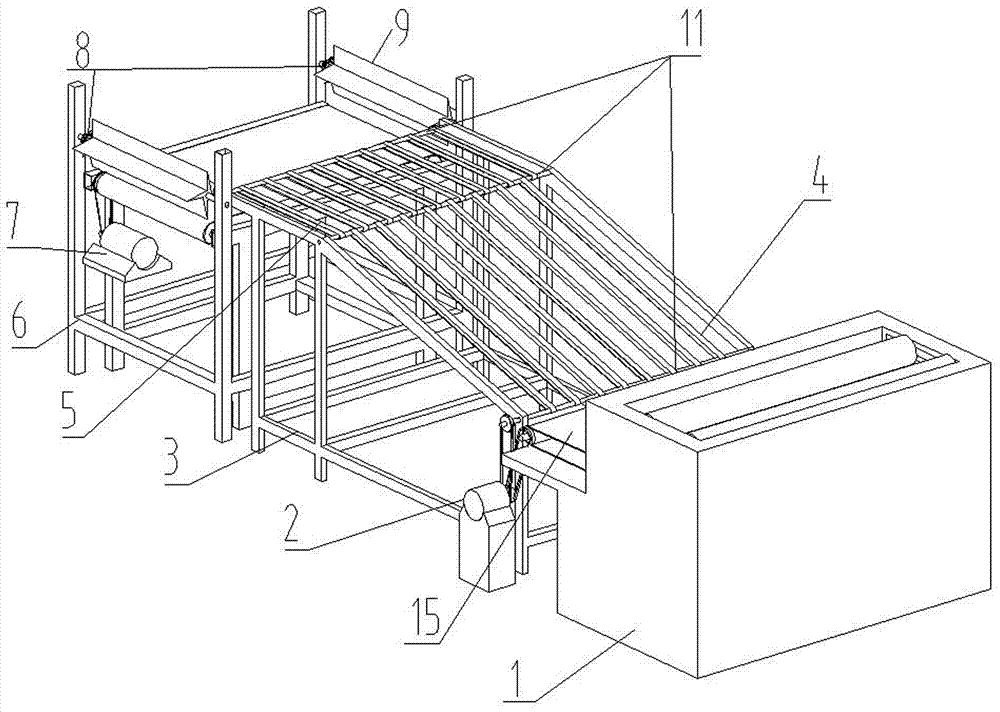

[0050] Such as figure 1 As shown, an automatic production device for round wood rotary cutting, drying and flattening stacked boards, the device includes a round wood rotary cutting conveying device 1000, a veneer drying and flattening device 2000 and a stacking board device 3000; wherein the round wood rotary cutting and conveying The device 1000 mainly plays the role of rotary cutting the round wood, processing it into a board of a specified size and transporting it to the next process; the veneer drying and flattening device 2000 can dry and flatten the board; the stacking device 3000 can stack the finished boards in an orderly manner, which is convenient for the final packing of the boards.

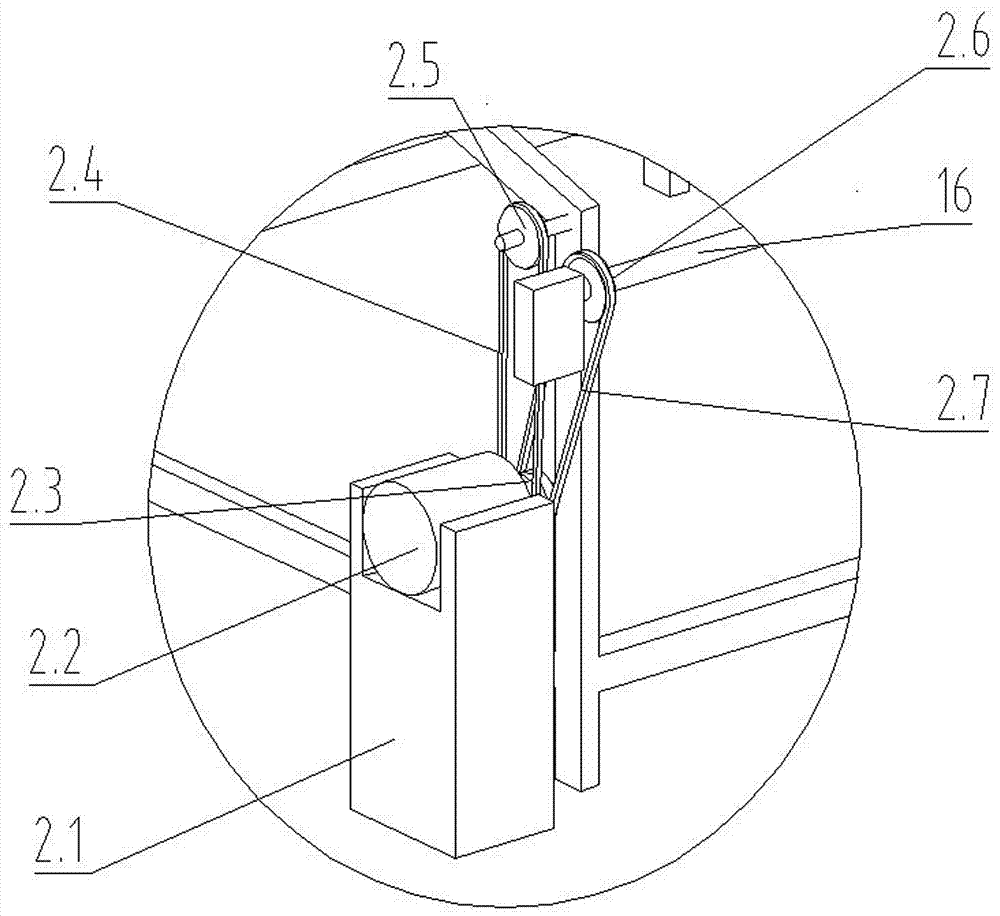

[0051] Such as Figure 2 to Figure 9 As shown, the round log rotary cutting conveying device includes a rotary cutting machine 1, a conveying de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com