Handheld power tool and operation method thereof

The technology of a power tool and operation method, which is applied in the field of hand-held power tools, can solve the problems of inconvenient operation, unsafe operation, heavy weight, etc., and achieve the effect of convenient operation, safe operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

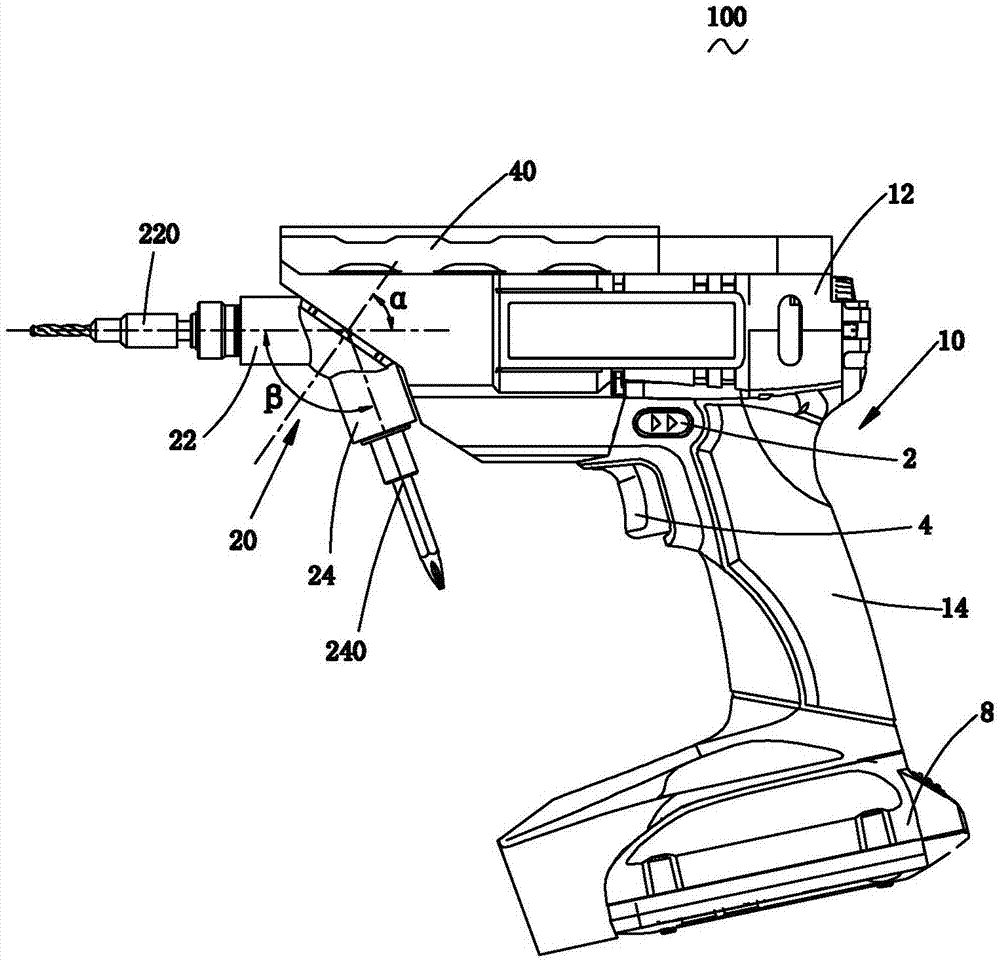

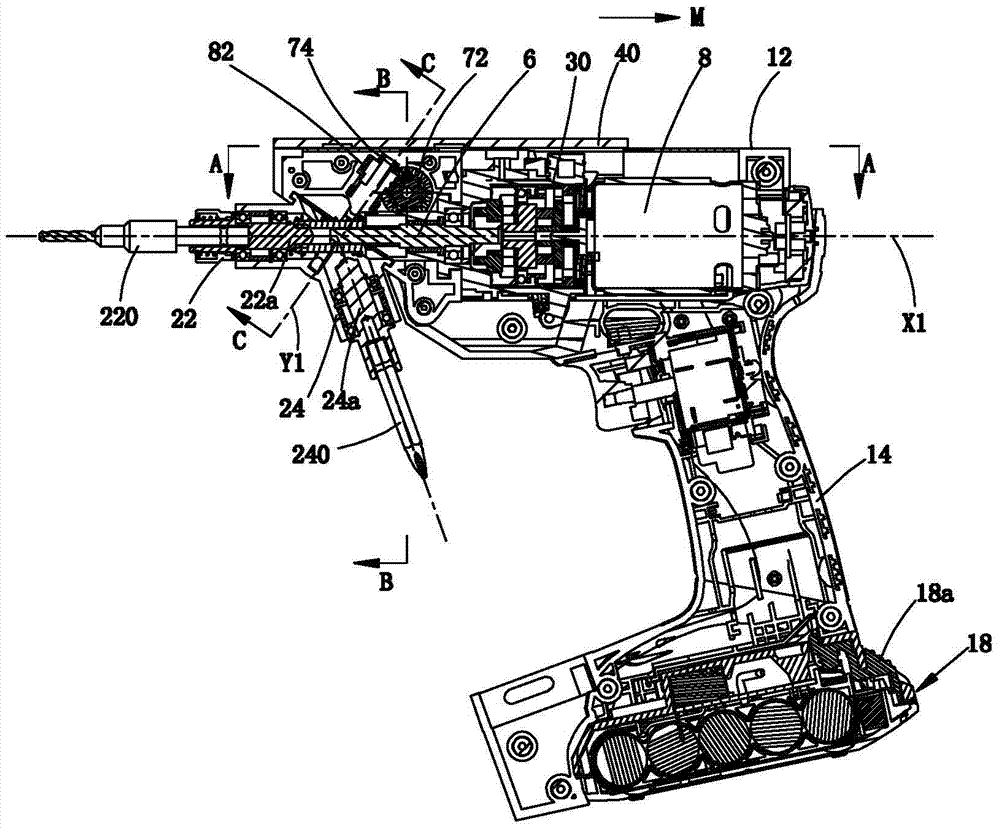

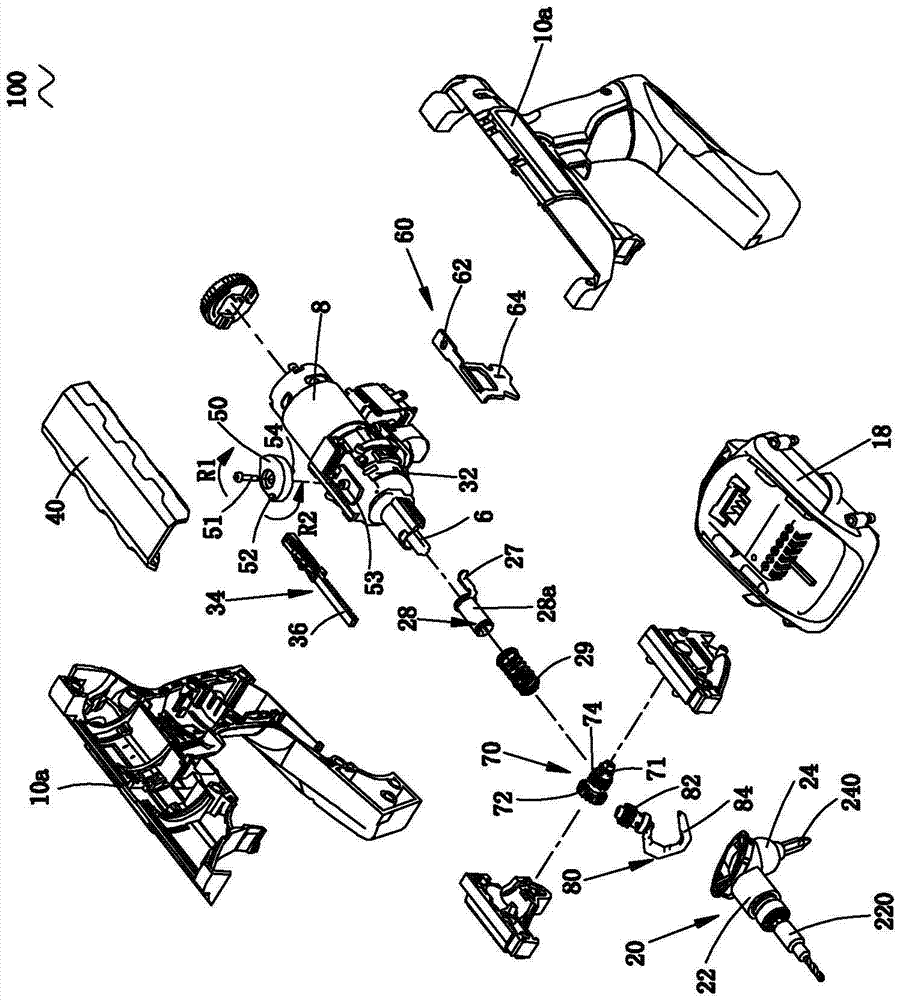

[0166] refer to Figure 1 to Figure 3 As shown, the hand-held power tool 100 of the present invention is provided with a casing 10, wherein the casing 10 is composed of two half-shells 10a of Huff type connected. The power system includes a motor 8 housed in the casing 10. The motor 8 in this embodiment is an electric motor, and other types of motors, such as air motors and fuel motors, can also be used instead. The housing 10 includes a main housing 12 for housing the motor 8 , and a handle 14 connected to the main housing 12 , the main housing 12 extends along the longitudinal direction, and the handle 14 is arranged at an angle to the main housing 12 . In this embodiment, the main housing 12 and the handle 14 of the multifunctional electric drill 100 are arranged approximately vertically. The end of the handle 14 away from the motor 8 is provided with an energy unit that provides energy for the motor 8. The energy unit in this embodiment uses a battery pack 18, which is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com