Vacuum press-fitting equipment suitable for interference assembly of shaft parts with blind holes

A shaft parts, vacuum technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as inappropriateness, and achieve the effect of easy operation, easy placement of workpieces, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

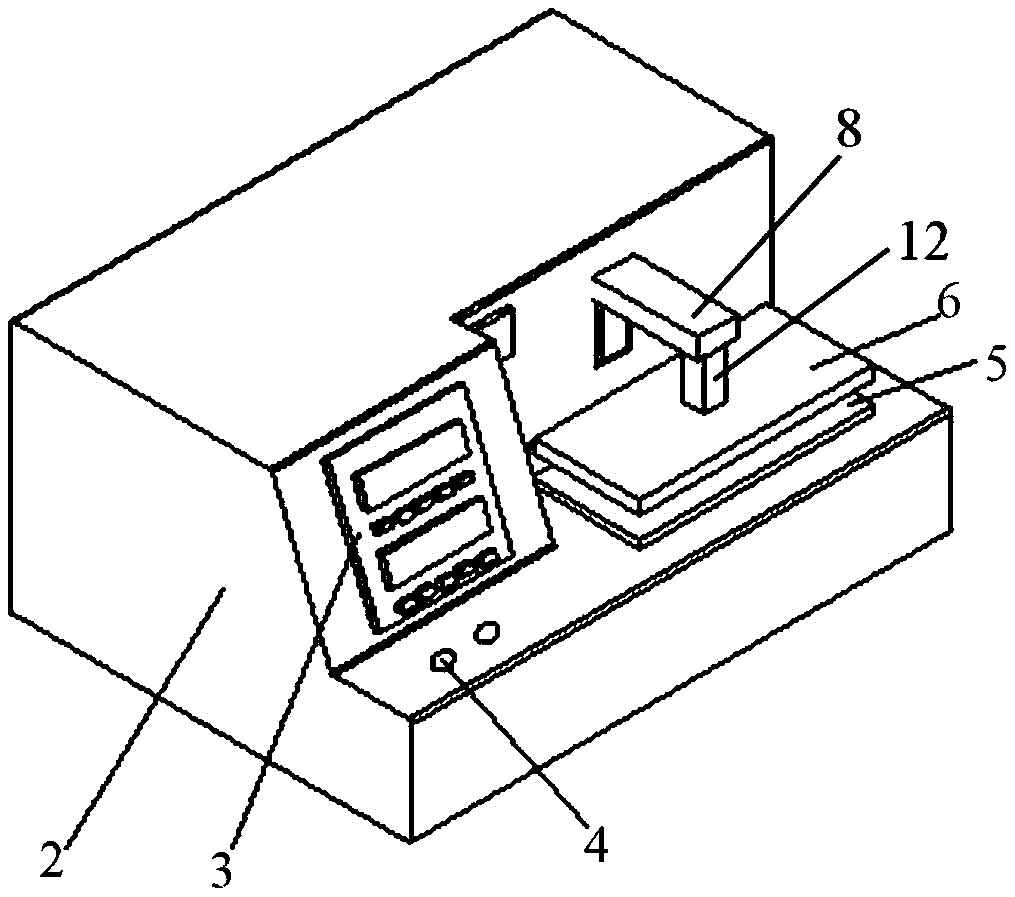

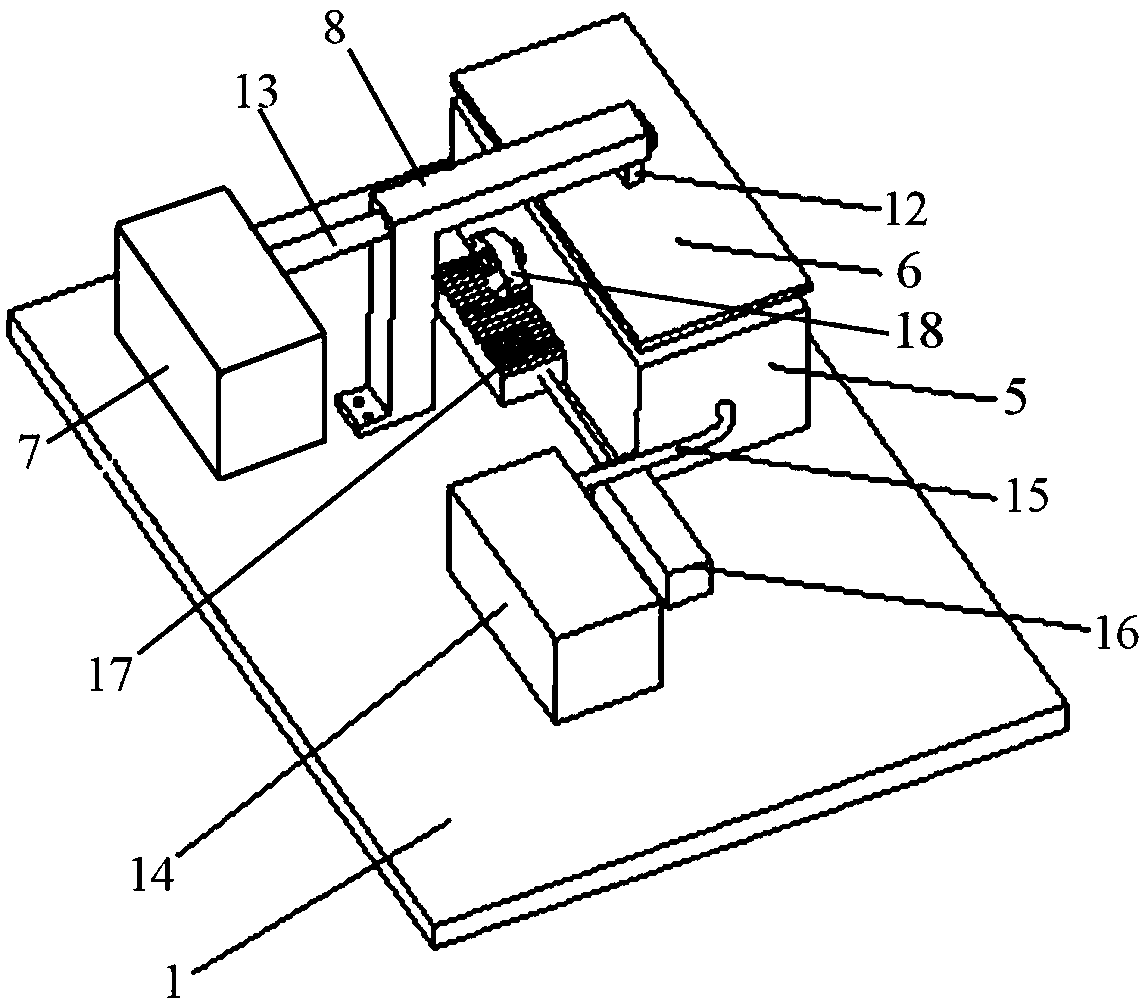

[0039] The vacuum press-fitting equipment suitable for the interference assembly of shaft parts with blind holes will be described in detail below in conjunction with the drawings and embodiments of the description:

[0040] like Figure 2-7 As shown, a vacuum press-fitting equipment suitable for interference assembly of shaft parts with blind holes, including a mounting plate 1 and a housing 2 fixed on it, a control system is installed inside the housing 2, and a display is installed on the outer wall 3 and the start button 4; also includes a press-fit chamber 5 arranged inside the shell, a cover drive mechanism, a vacuum mechanism, a press-fit transmission mechanism and a cover plate 6 arranged directly above the press-fit chamber 5 and placed outside the shell 2.

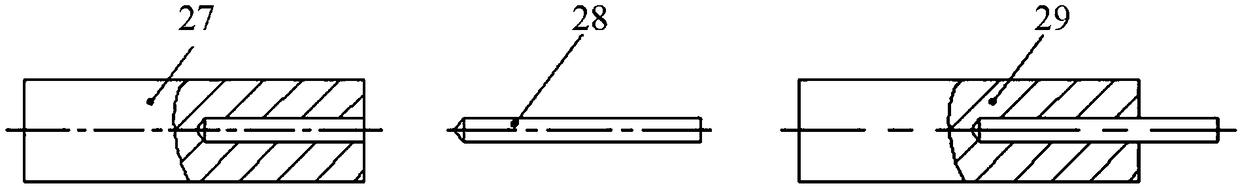

[0041] The press-fitting chamber 5 is a hollow cuboid structure with an open top, a horizontal through hole 25 is formed on one side wall of the press-fitting chamber 5, and a part placement groove 26 is formed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com