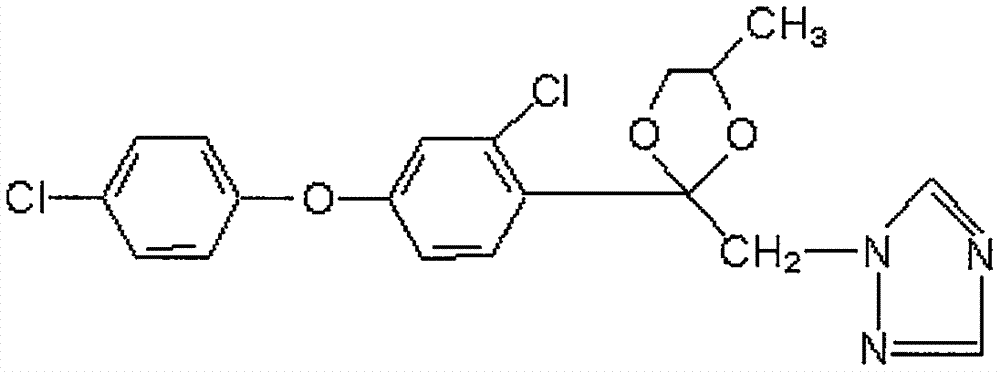

Difenoconazole and thiophanate methyl compound suspension and preparation method thereof

A technology of difenoconazole and thiophanate-methyl, which is applied in botany equipment and methods, biocides, fungicides, etc., can solve the problems of drug resistance of bacteria and the use of carbendazim in rotation, and achieve low production costs , less drug resistance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

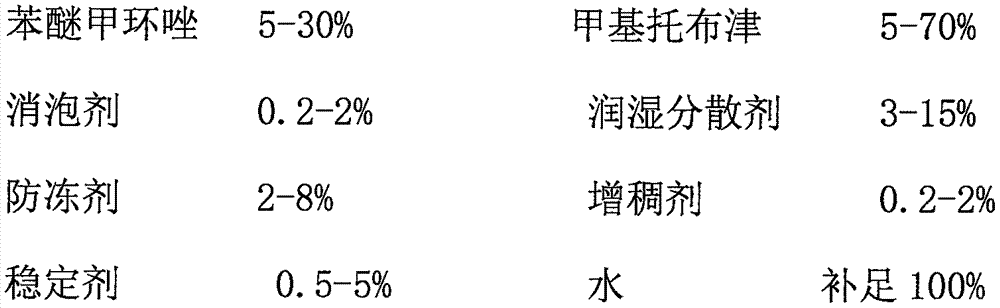

[0025] Example 1: 50% difenoconazole·thiophanate methyl: the content of each component (by weight) contains 30% difenoconazole, thiophanate methyl 20%, wetting and dispersing agent dodecane Base polyoxyethylene ether phosphate 5%, open powder 1%, thickener xanthan gum 0.2%, stabilizer dinaphthol 0.5%, defoamer silicone defoamer 0.2%, antifreeze ethylene glycol 4 %, add deionized water to make up 100%.

[0026] Preparation process: firstly mix difenoconazole and thiophanate methyl, then add the wetting and dispersing agent according to the proportion and stir well, then add the defoamer, thickener, stabilizer, antifreeze and deionization in sequence Add water while stirring, and mill it in a ball mill for 2-5 hours to make the particle size of difenoconazole and thiophanate methyl all below 5um.

[0027] The preparation process of the following examples is similar to this.

Example Embodiment

[0028] Example 2: 50% difenoconazole·thiophanate methyl: the content of each component (by weight) contains 20% difenoconazole, 30% thiophanate methyl, wetting and dispersing agent alkyl naphthalene Formaldehyde condensate sulfonate 7%, thickener sodium carboxymethyl cellulose 0.2%, stabilizer sodium benzoate 0.5%, defoamer n-octanol 0.2%, antifreeze glycerol 4%, plus deionized water to make up 100%.

Example Embodiment

[0029] Example 3: 60% difenoconazole·thiophanate methyl: the content of each component (by weight) contains 10% difenoconazole, thiophanate methyl 60%, wetting and dispersing agent lauryl alcohol poly Sodium oxyethylene ether sulfate 8%, sodium dodecylbenzene sulfonate 3%, thickener polyethylene glycol 0.2%, stabilizer BHT 0.5%, defoamer silicone defoamer 0.2%, antifreeze propylene glycol 4 %, add deionized water to make up 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com