Drum assembly in a leather tanning plant

A roller and leather technology, applied in the field of machinery, can solve problems such as reduced service life, roller damage, and increased use costs, and achieve the effects of improving stability, prolonging service life, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

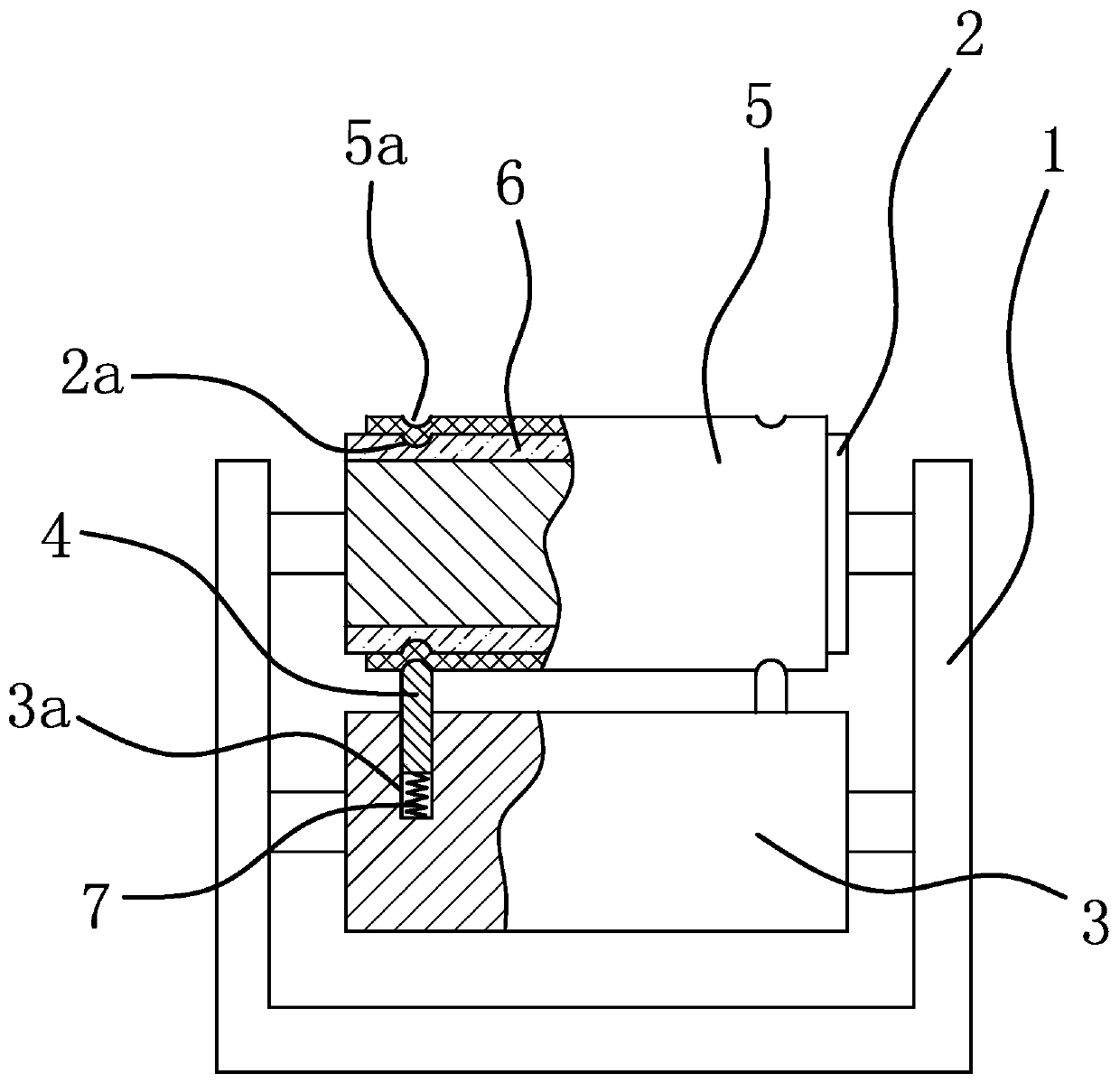

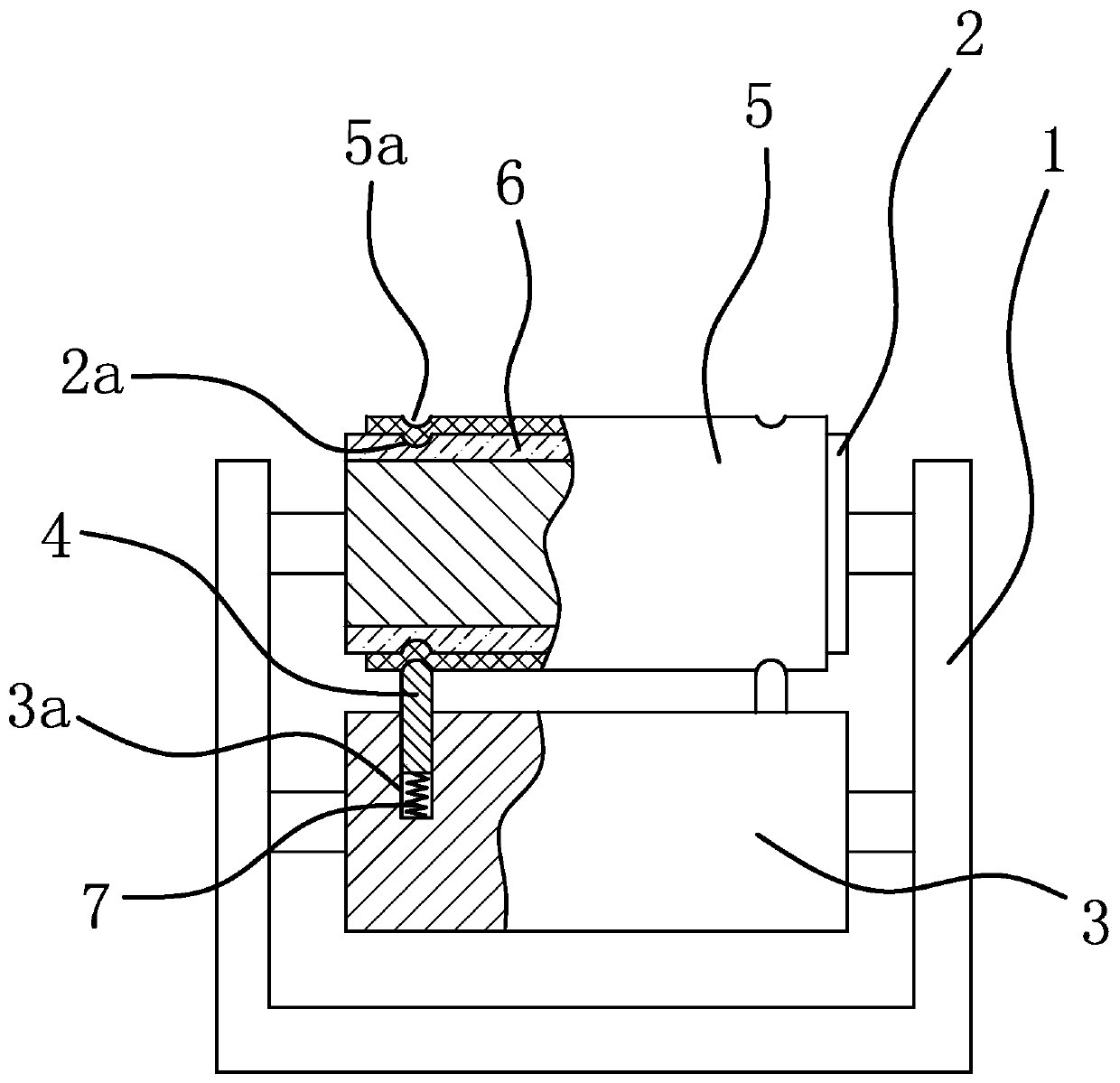

[0030] Such as figure 1 As shown, the drum assembly in the genuine leather tanning device, the leather tanning device includes a frame 1, an upper drum 2 and a lower drum 3, the upper drum 2 and the lower drum 3 are arranged in parallel and both are axially fixed on the above frame 1, a pressing gap is formed between the upper cylinder 2 and the lower cylinder 3 for the leather raw material to be pressed through. The two ends of the lower cylinder 3 have protruding limit edges 4, and the above limit edges 4 abut against On the upper roller 2 and between the upper roller 2, the lower roller 3 and the limit edge 4, a pressing part matching the leather material is formed. The outer side of the upper roller 2 is covered with a cylindrical contact sleeve 5. The above limit edge There is an elastic mechanism between 4 and the lower roller 3, and the above-mentioned limit edge 4 has a tendency to abut against the contact sleeve 5 under the action of the elastic mechanism.

[0031] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com