Warehouse fire safety automatic patrol robot

A safe automatic and robotic technology, applied in the field of robotics, can solve problems such as changing fire compartments, fire distances, changing the properties of stored materials in warehouses, and not maintaining the distance between lights, etc., to improve work efficiency, save labor costs, and reduce work pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

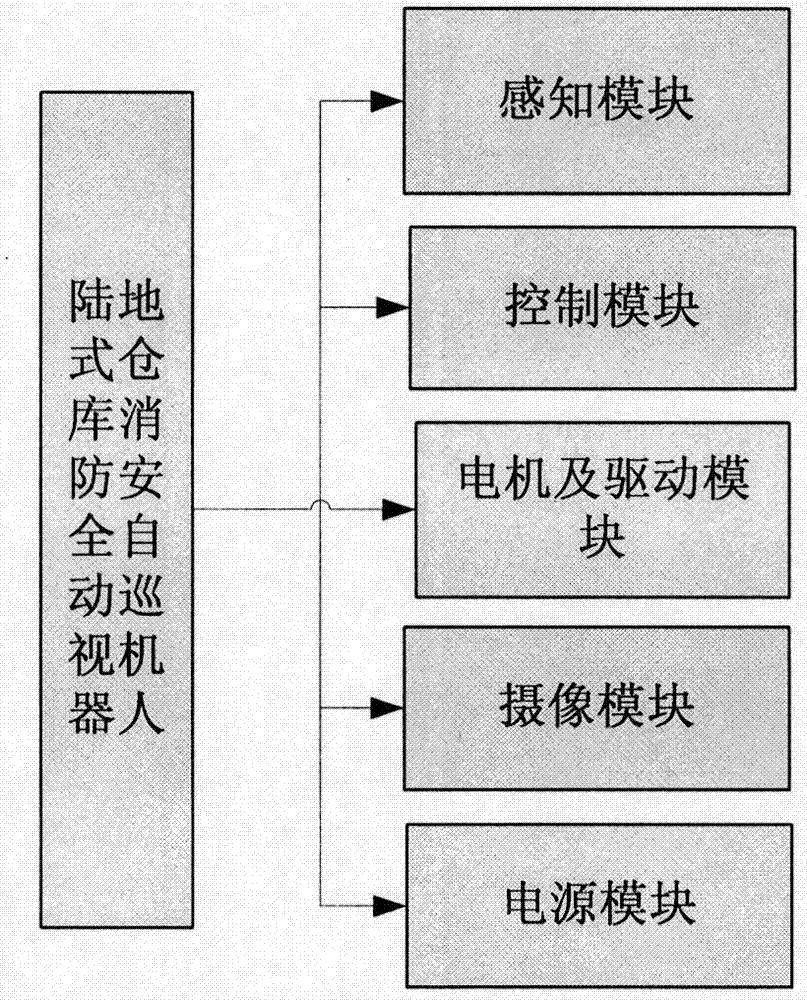

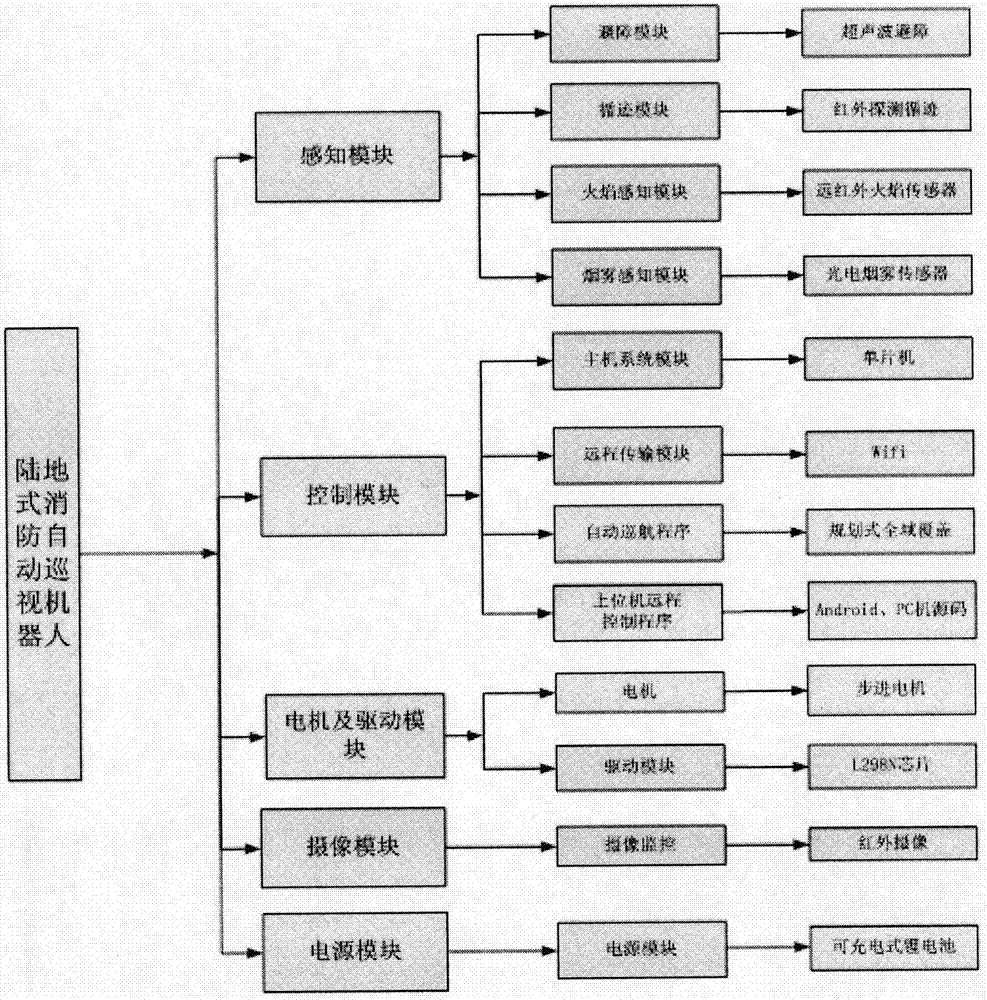

[0027] Such as figure 1 As shown, the warehouse fire safety automatic patrol robot proposed by the present invention is specifically a land-type warehouse fire safety automatic patrol robot, including:

[0028] Perception module: used to realize the perception of the surrounding environment of the warehouse fire safety automatic inspection robot;

[0029] Control module: used to realize the control of the warehouse fire safety automatic inspection robot;

[0030] Motor and drive module: used to realize the drive of the warehouse fire safety automatic inspection robot;

[0031] Camera module: used to realize shooting and video recording of objects appearing around the warehouse fire safety automatic inspection robot;

[0032] Power module: used to provide power for the warehouse fire safety automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com