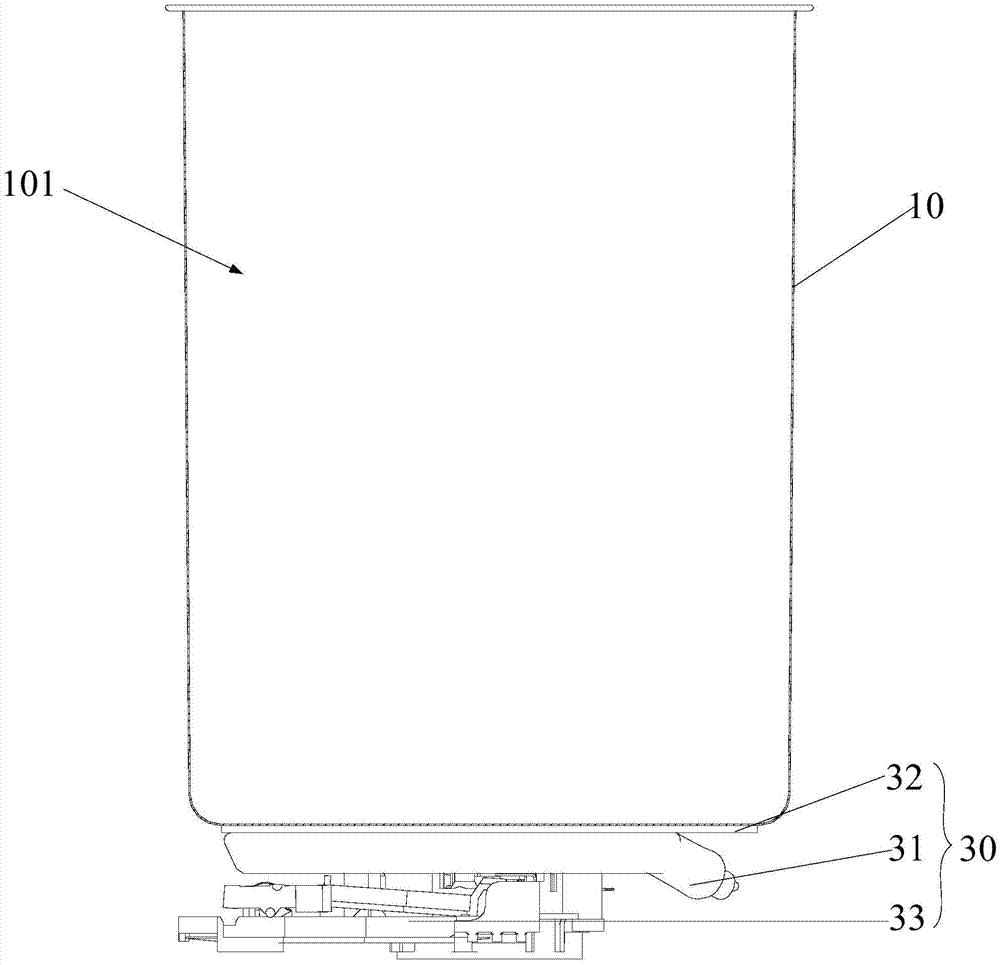

Liquid heating container

A liquid heating container and liquid technology, applied in heating devices, cooking utensils, water boiling utensils, etc., can solve the problems of loud noise, affecting people's daily life and work, and inconvenience to consumers, so as to prolong the service life and increase the Market competitiveness and the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

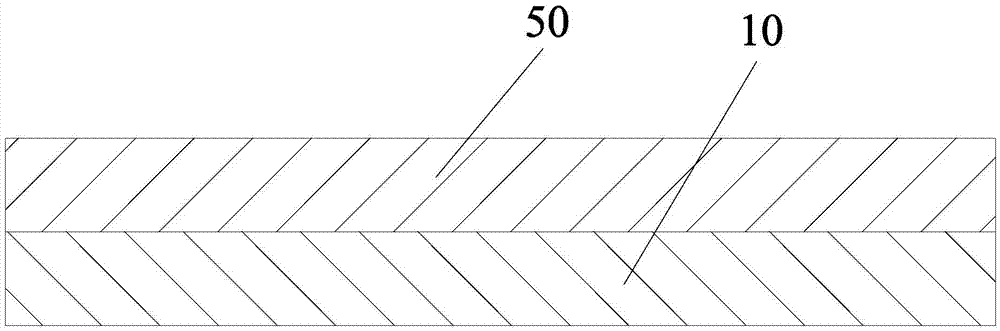

specific Embodiment 1

[0094] The surface-treated kettle liner has a fluorine-containing coating. The thermal conductivity of the coating is 0.35W / (m K), the coating thickness is 20μm, the hardness is 3H, and the contact angle with the coating is 103°. The kettle is heated The power is 1500W, and the heating power density is 12W / cm 2 , When the kettle is boiling water normally, the maximum temperature on the surface of the heating plate is 105°C, and the maximum noise during the boiling process of the kettle is 51dB, while the noise of the kettle without surface treatment is 62dB, which has a good noise reduction effect.

specific Embodiment 2

[0096] The surface-treated kettle liner has a ceramic coating. The thermal conductivity of the coating is 1.0W / (m K), the coating thickness is 30μm, the hardness is 6H, and the contact angle with the coating is 108°. The heating power of the kettle is 1800W, heating power density is 15W / cm 2 , When the kettle is boiling water normally, the maximum temperature on the surface of the heating plate is 110°C, and the maximum noise during the boiling process of the kettle is 52dB, while the noise of the kettle without surface treatment is 62dB, which has a good noise reduction effect.

[0097] To sum up, in the liquid heating container provided by the present invention, a coating is formed on the inner wall of the container body. The coating is flat when viewed directly, but has a microscopic concave-convex structure, which is easy to form gasification cores on the coating. The gasification core grows to form bubbles, and when the bubbles grow to an appropriate size, they leave the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com