Method and exhaust gas aftertreatment system for detecting the loading of a particle-filtering component

A technology for exhaust gas post-treatment and equipment, which is applied in exhaust gas treatment, electronic control of exhaust gas treatment devices, diagnostic devices of exhaust gas treatment devices, etc., and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

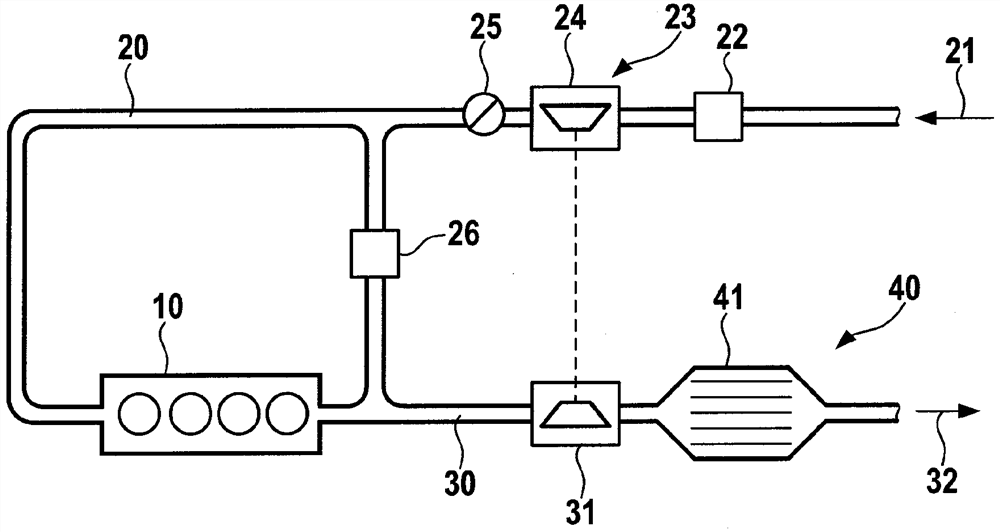

[0026] figure 1 By way of example, a simplified schematic diagram of an air and exhaust air duct in the environment of a motor vehicle with an internal combustion engine 10 in which the method according to the invention can be used is shown. The supply air flow 21 first passes through the air mass sensor 22 via the air delivery channel 20 before the supply air flow 21 is fed via the compression stage 24 of the turbocharger 23 and the throttle valve 25 of the internal combustion engine 10 . In internal combustion engine 10 , air is converted exothermicly together with the supplied fuel (not shown here). The exhaust gas generated can be partially resupplied to the supply air flow 21 via the exhaust gas recirculation 26 . The remaining exhaust gas flow 32 is conducted via the exhaust duct 30 first via the exhaust gas turbine 31 of the turbocharger 23 and then into the exhaust gas aftertreatment device 40 . A four-way catalytic converter 41 is arranged in the exhaust gas aftertr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com