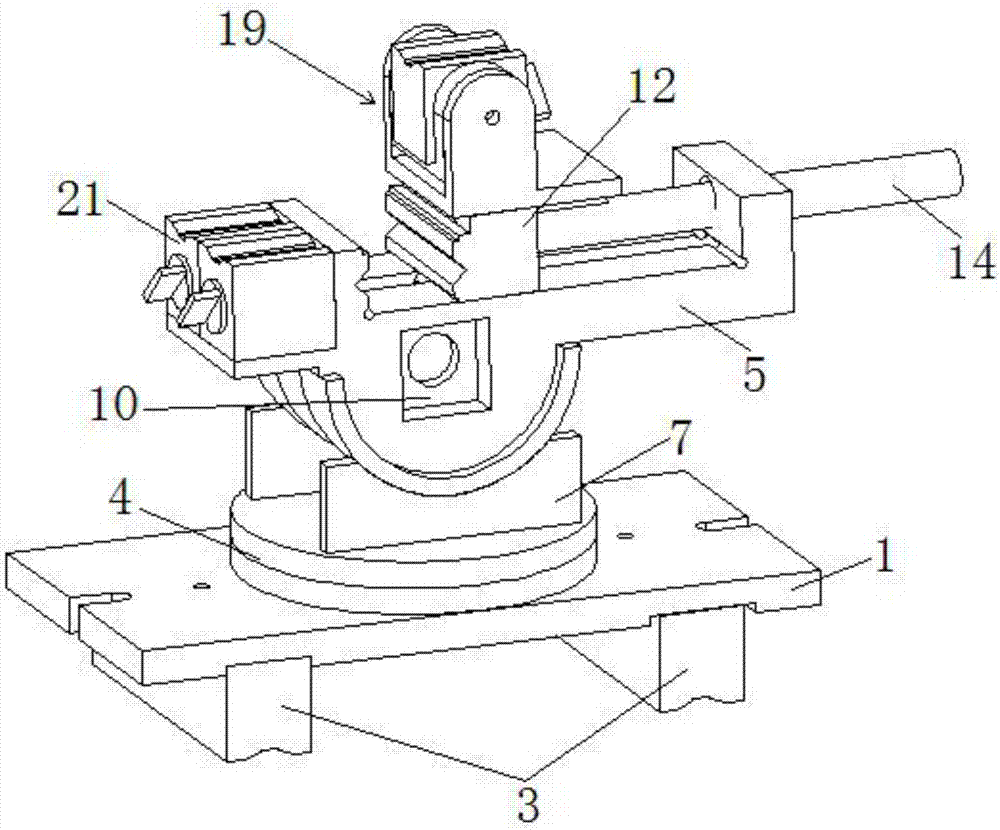

Laser machining clamp

A laser processing and fixture technology, applied in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of heat accumulation and dissipation speed, which have a great influence on the processing process, fast heat conduction, and poor clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

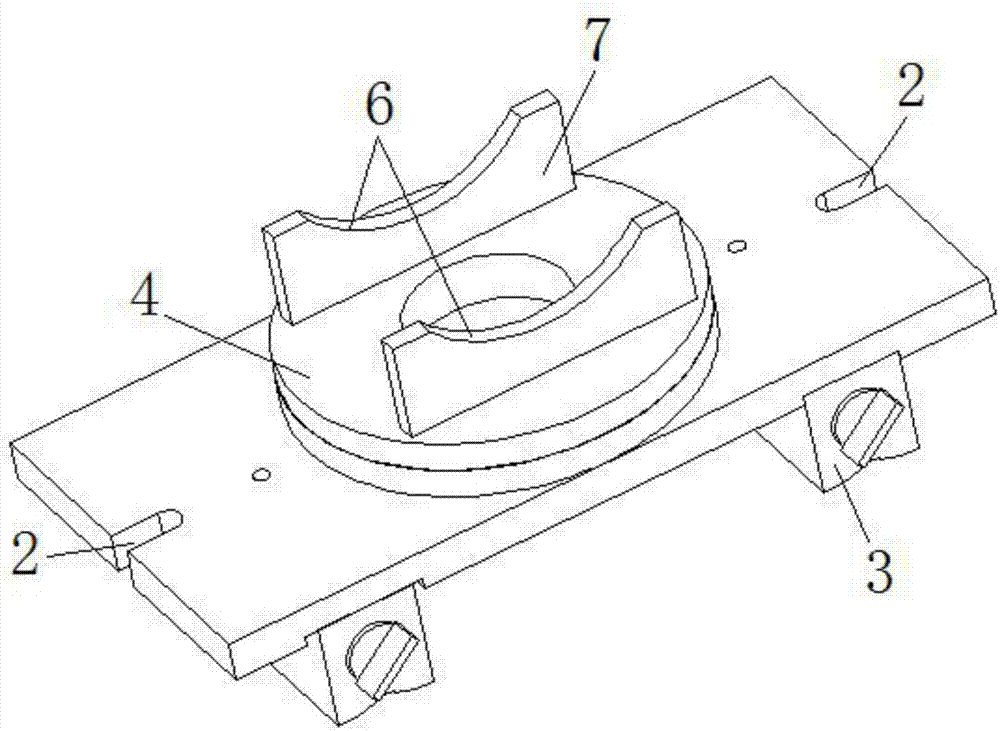

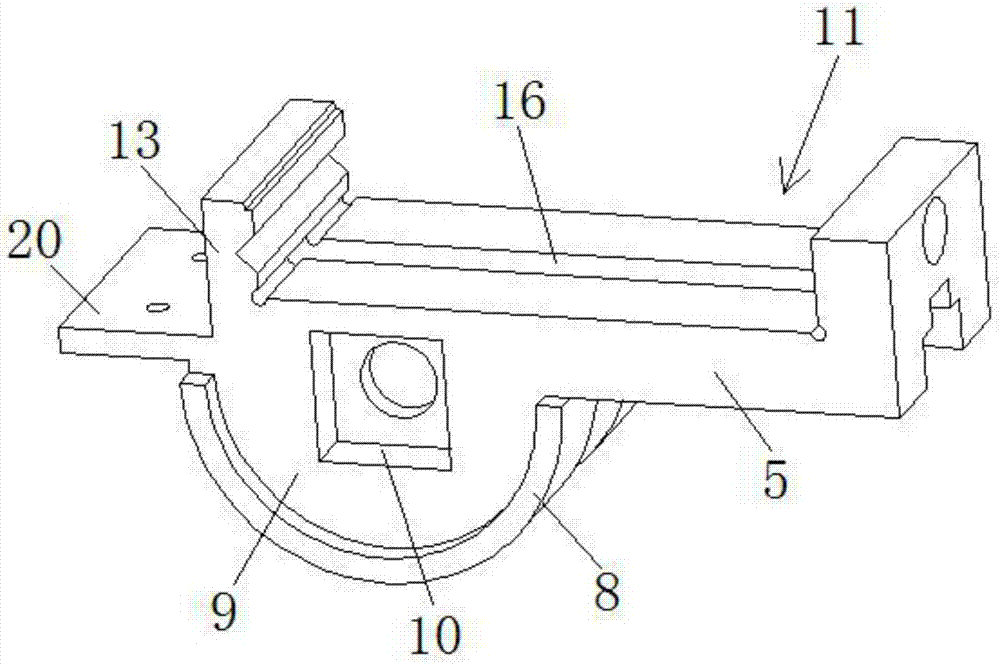

[0032] Based on the fact that laser processing is a process of rapid heating and rapid cooling, the speed of heat accumulation and dissipation has a great influence on the processing process. The workpiece is directly placed on the rotary table, and the heat conduction is fast, which will affect the analysis of the actual distribution of laser heat on the steel plate. However, if the workpiece is placed on an ordinary vise, if the cutting surface of the steel plate is uneven, the clamping effect will not be good. It is not easy to guarantee the level. Furthermore, when carrying out cladding experiments on inclined surfaces in space, the vise is fixed on the rotary table, and the vise and the stainless steel plate can be rotated to a certain angle with the help of the rotation of the rotary table, but the angle cannot be accurately measured. Although the tiltable flat vise can rotate the stainless steel plate at a certain angle, the same problem as the ordinary vise will appear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com