A power lithium-ion battery pole piece slurry production line

A lithium-ion battery and production line technology, which is applied to battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of easy sedimentation of slurry, poor controllability, and difficulty in mixing materials uniformly, so as to improve homogeneity and Dispersion efficiency, increased shearing force, and the effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

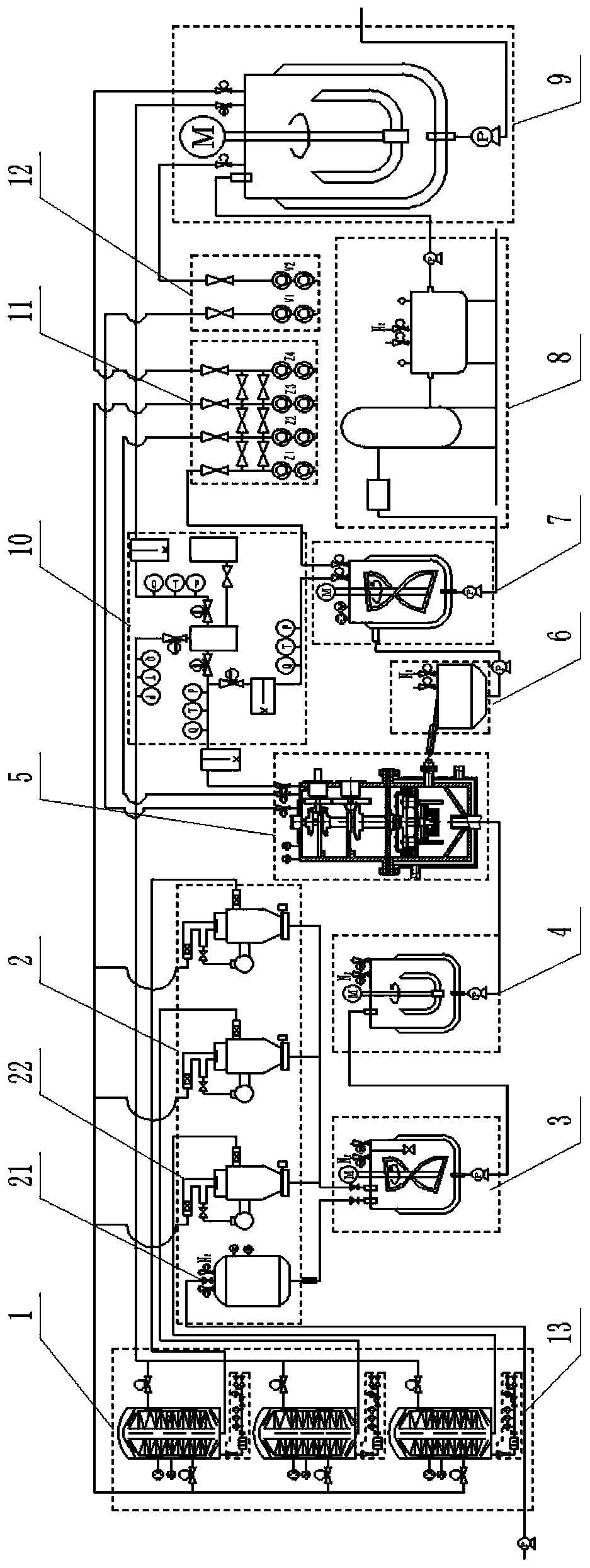

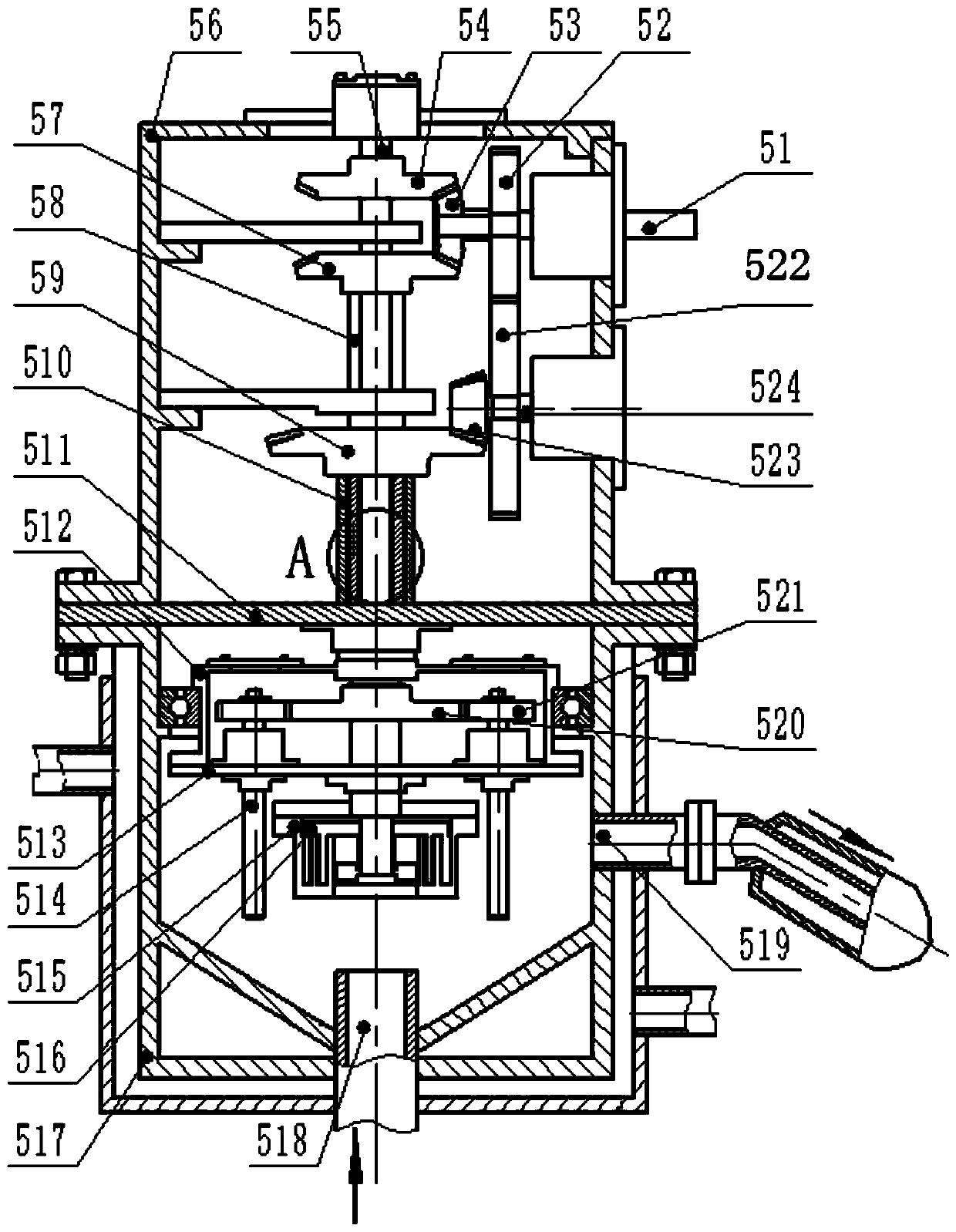

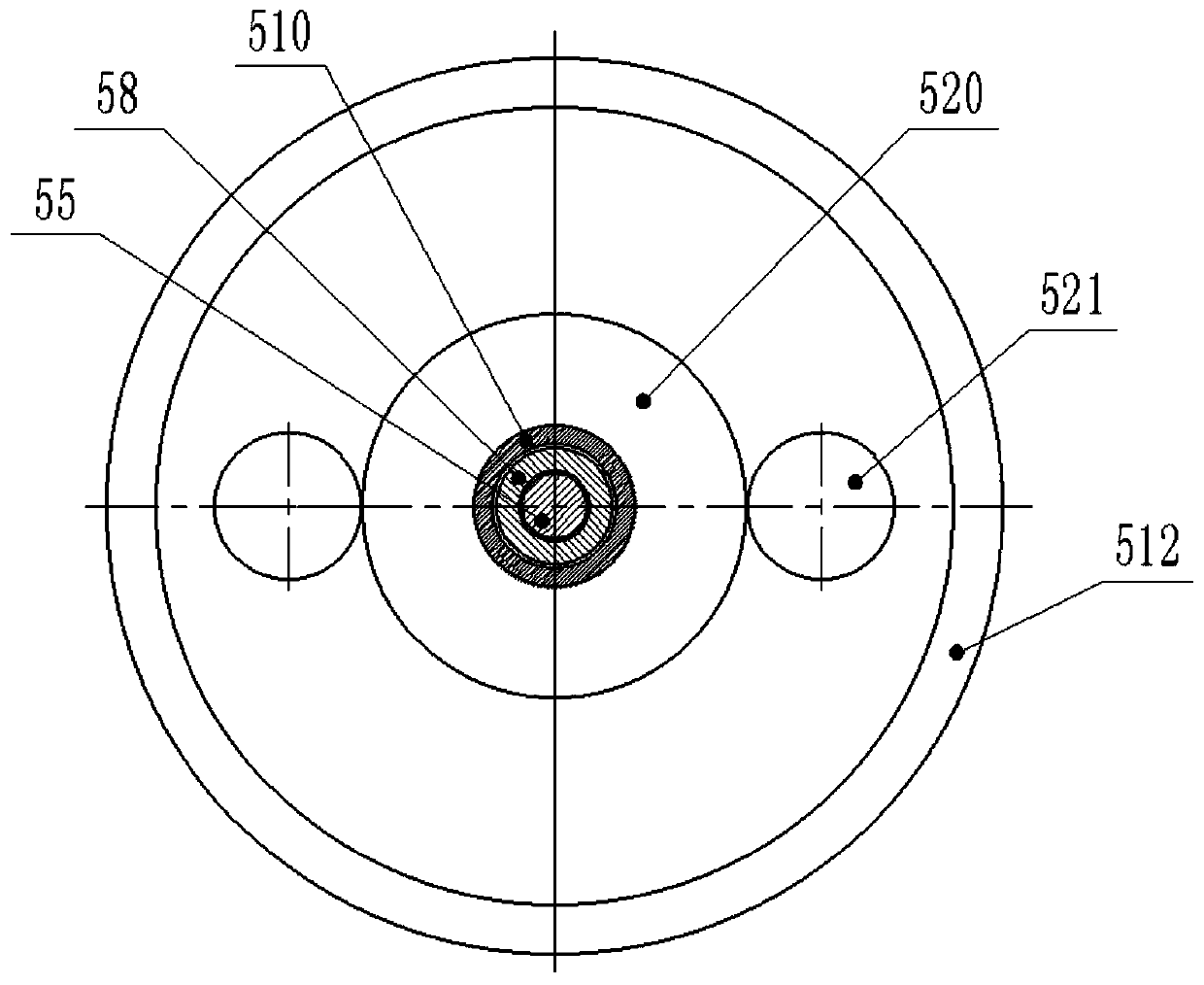

[0030] The invention provides a production line for power lithium-ion battery pole piece slurry (see Figure 1-6 , referred to as the production line), is characterized in that the production line includes a raw material storage device 1, a feeding device 2, a premixing device 3, a slurry storage device 4, a high-speed stirring device 5, a buffer device 6, a turnover device 7, a filtering device 8, Finished product storage device 9, nitrogen charging and discharging device 10, vacuum pumping device 11, vacuum maintaining device 12 and vacuum bypass device 13; the feeding device 2 includes a solvent feeding device 21 and a powder feeding device 22;

[0031] The raw material storage device 1 is located at the front end of the entire producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com