Anti-clogging filter head with no handle applied to water treatment biological filter tank

A biological filter and anti-clogging technology, applied in the field of water treatment, can solve the problems of decreased flow capacity, easy blockage of air distribution holes and air distribution joints, increased loss of filter water head, etc., and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

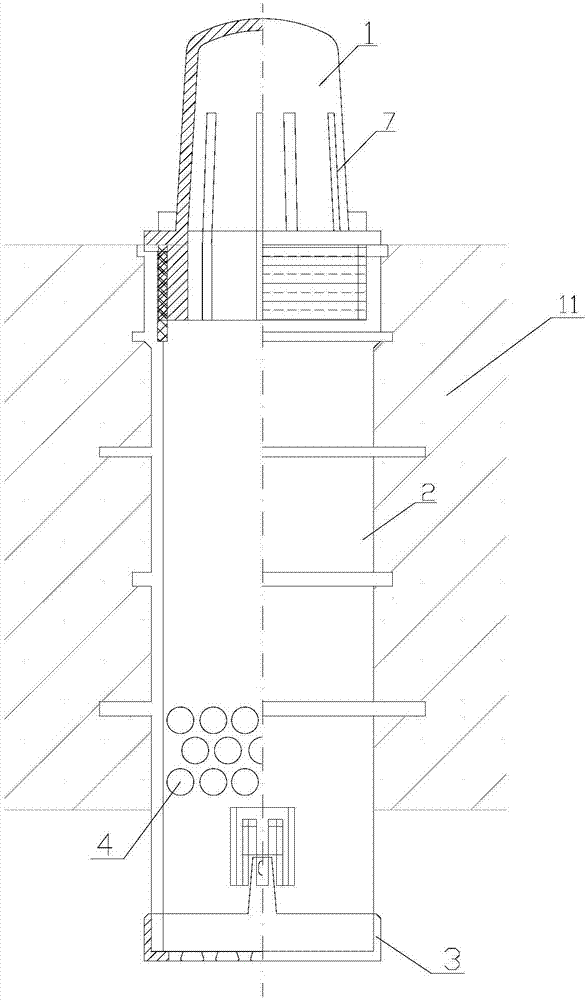

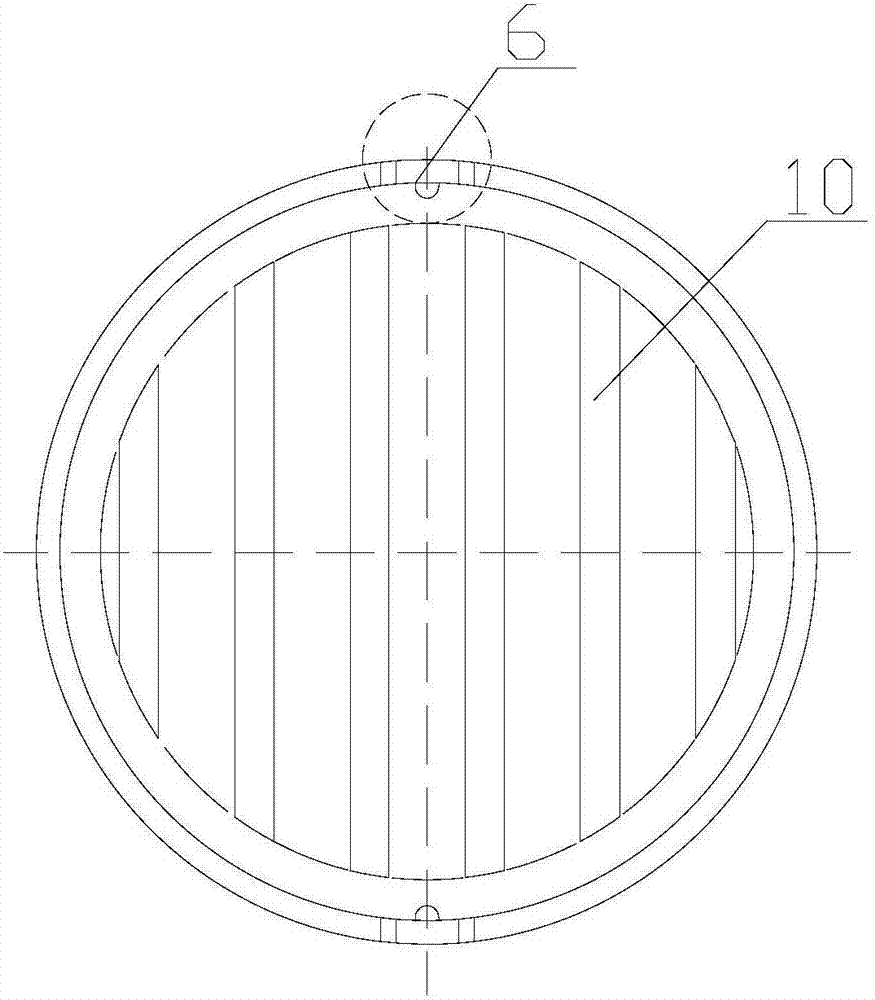

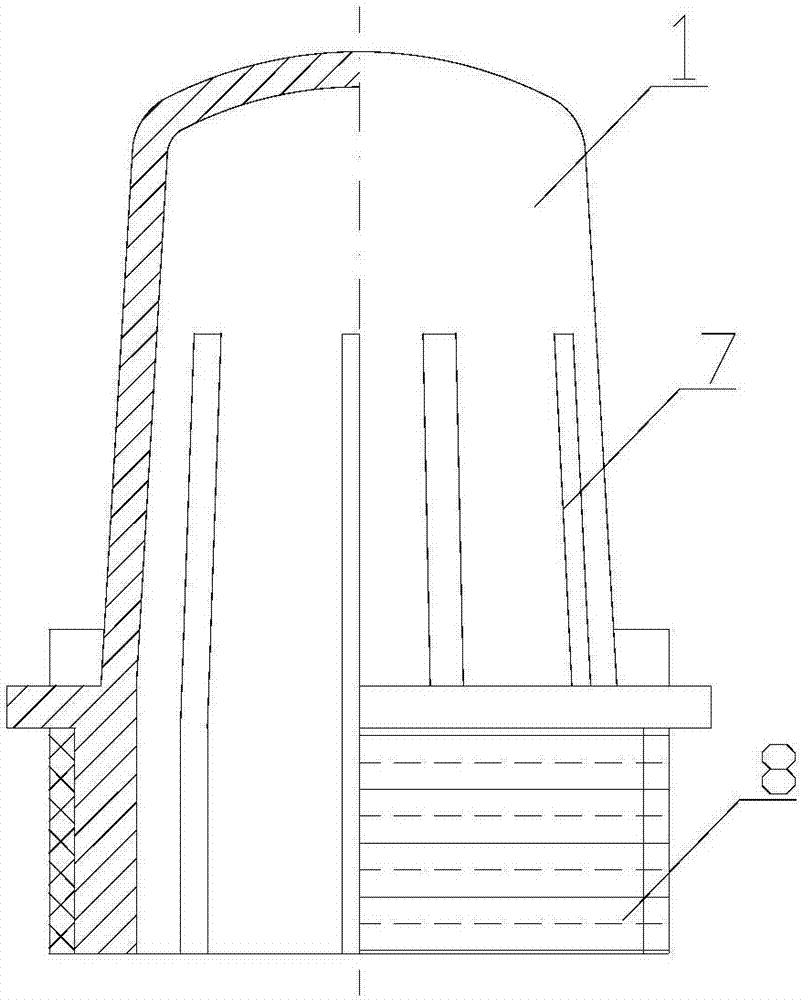

[0033] Such as Figure 1 ~ Figure 4 As shown, the anti-clogging sessile filter head used in the water treatment biological filter includes an upper filter cap 1, a pre-embedded seat 2, a lower filter cap 3 and a self-cleaning bead 4; the pre-embedded seat 2 is fixed on the filter plate of the filter 11. The upper filter cap 1 is threadedly connected to the pre-embedded seat 2; the lower filter cap 3 is flexibly connected to the pre-embedded seat 2; multiple self-cleaning beads 4 are placed in the pre-embedded seat 2 between the upper filter cap 1 and the lower filter cap 2 In the cylindrical cavity of the embedded seat 2, the diameter of the cylindrical cavity in the embedded seat 2 is 45-50 mm, and the height is consistent with the thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com