Capping device

A cover cover and conveying path technology, which is applied in the field of capping devices, can solve problems such as hidden dangers in the operation of capping devices, short cap conveying paths, and weak anti-risk capabilities, and achieve structural optimization, safety and convenience of cap conveying paths The effect of improving and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

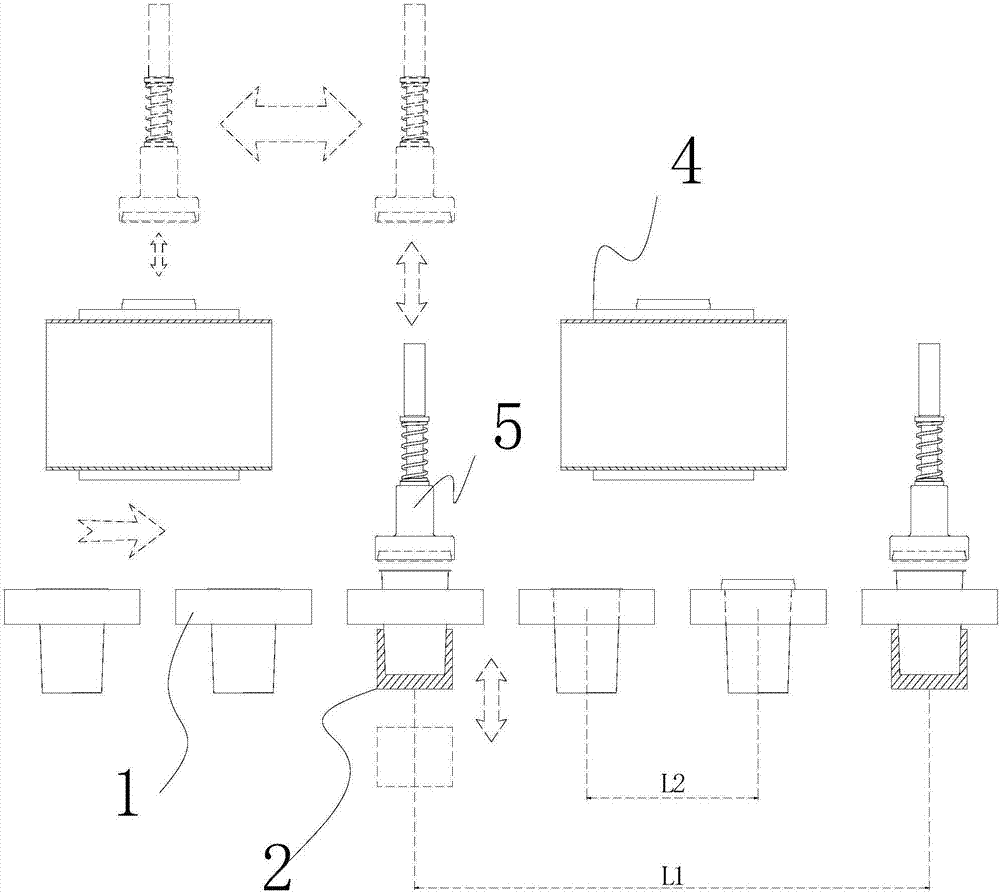

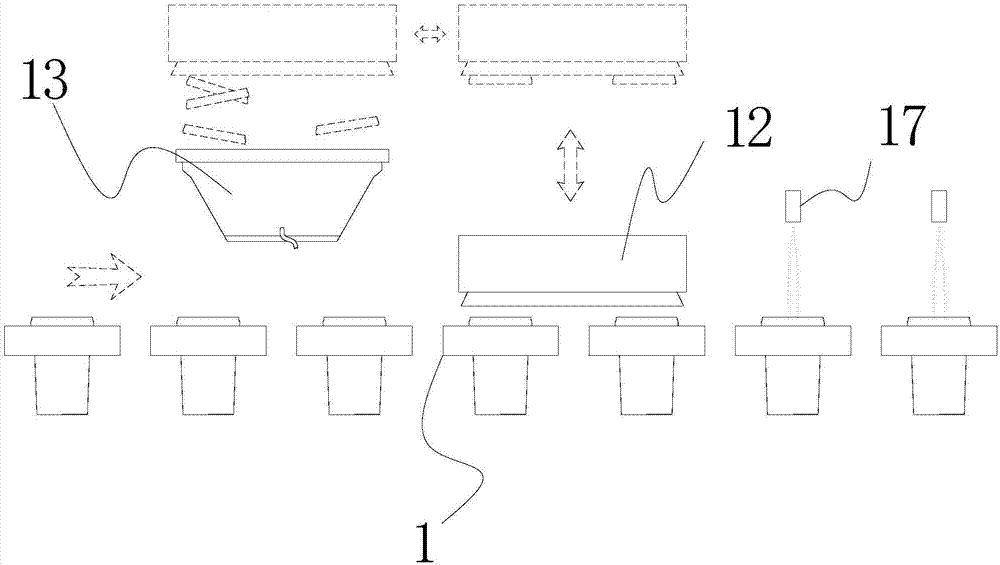

[0026] The capping device includes a frame, a cup conveying component, a handling component, a cap conveying component, a capping supporting component, and a rejecting component.

[0027] The cup conveying assembly includes a chain, a template 1, a gear, and a motor. The gear is installed on the frame through the rotating shaft, and the gear can rotate. Two gears are installed on one rotating shaft, and four gears are installed on the frame. The motor is installed on the frame and connected with the gear, and the motor can drive the gear to rotate. The cup conveying assembly is provided with two chains, and each chain is installed on the gears on the two rotating shafts on the same side, and the chains are driven to move when the gears rotate. The template 1 is a flat cuboid structure as a whole, and there are eight through-hole structures arranged equidistantly on the template 1. These through-holes are arranged in the same straight line direction, and these through-holes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com