PCB body fixing mold device for PCB depaneling machine

A technology of PCB board and board splitting machine, which is applied to the processing of electrical components, insulating substrate/layer, and printed circuit manufacturing. The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

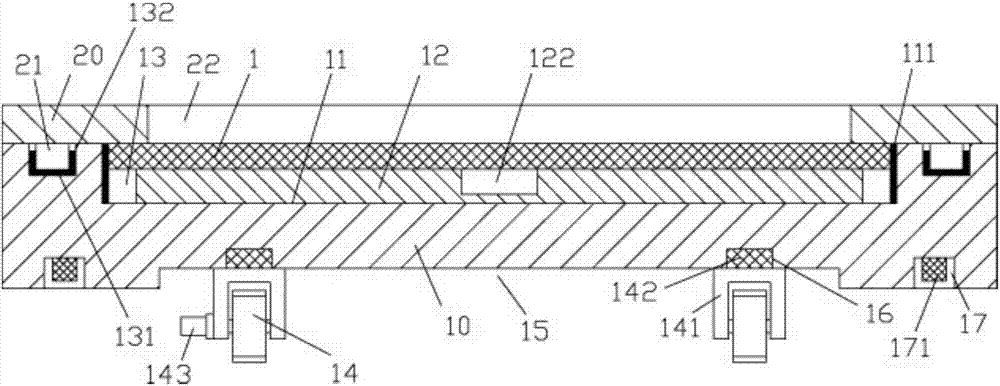

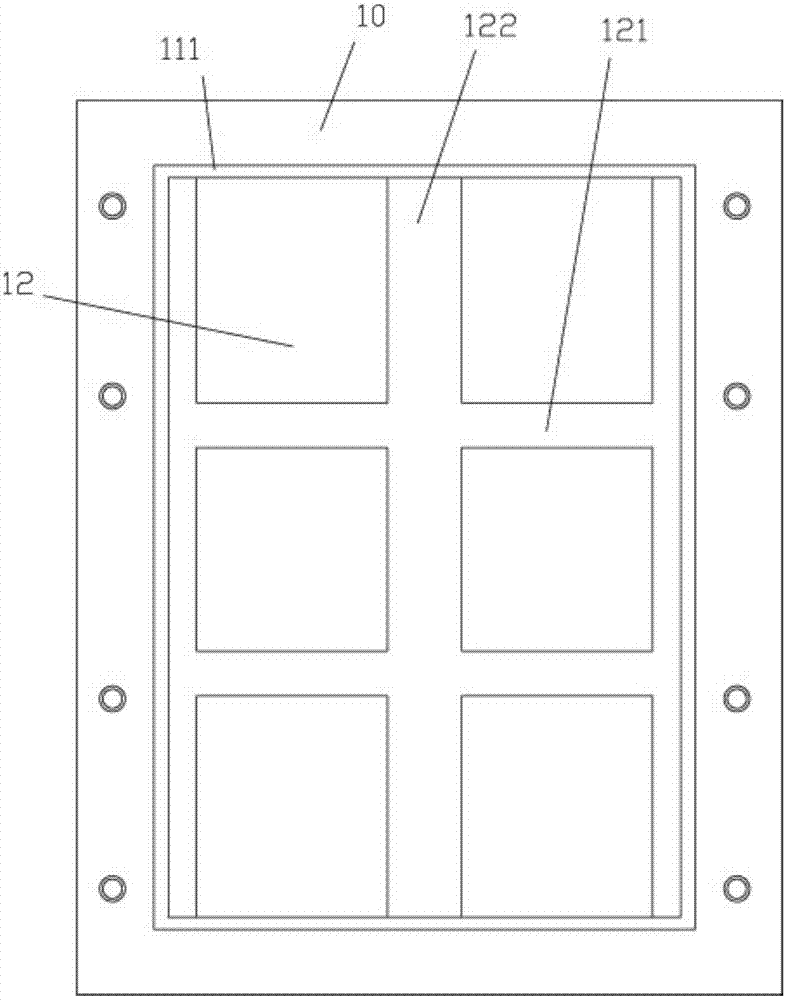

[0023] Examples, see e.g. Figure 1 to Figure 2 As shown, a PCB board body fixing mold device for a PCB splitting machine includes a lower mold 10, the middle part of the top surface of the lower mold 10 has a placement groove 11, and the bottom surface of the placement groove 11 has a mounting raised plate 12, There is an empty groove 13 between the installation raised plate 12 and the inner sidewall of the groove 11, and the middle part of the installation raised plate 12 has a plurality of parallel transverse grooves 121 and a vertical groove 122, the transverse groove 121 and the vertical groove 122. The vertical groove 122 evenly divides the mounting raised plate 12 into a plurality of raised parts;

[0024] The top surface edge of the lower mold 10 has a plurality of positioning concave holes 131, the upper platen 20 is pressed against the top surface of the lower mold 10, and the bottom surface edge of the upper platen 20 has a raised post 21, and the raised post 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com