A lifting method with anti-off and anti-single ring

An anti-dropping and lifting ring technology, which is applied in the directions of earthwork drilling, load hanging elements, drilling pipes, etc., can solve the problems of reduced safety and reliability in the operation process, inability to effectively block the lifting ring, and easy rotation of the lifting ring stopper. Reduce manual labor intensity, improve work stability and reliability, and prevent lifting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

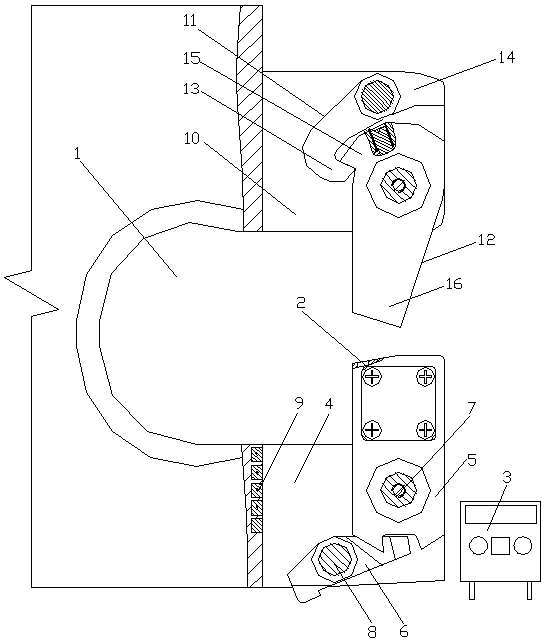

[0068] An anti-off and anti-single ring hoisting method, comprising the following steps:

[0069] a. Open the anti-off mechanism of the anti-off single ring lifting system, so that the anti-off mechanism is in the unlocked state;

[0070] b. When the lifting ring is installed into the ear hole 1 of the lifting lug on one side of the elevator, the sensing part 2 of the anti-loosening part sends out a signal, and after the controller 3 receives the signal, the controller 3 prohibits the movement of the traveling vehicle, and the traveling vehicle is in a stopped state; After the ring enters the ear hole 1, the anti-off mechanism is in a locked state, blocking the ring in the ear hole 1;

[0071] c. Put another lifting ring into the ear hole 1 of the lifting lug on the other side of the elevator, the sensing part 2 of the anti-off part sends out a signal, and the controller 3 allows the traveling vehicle to move after receiving the signal.

[0072] This embodiment is the most ba...

Embodiment 2

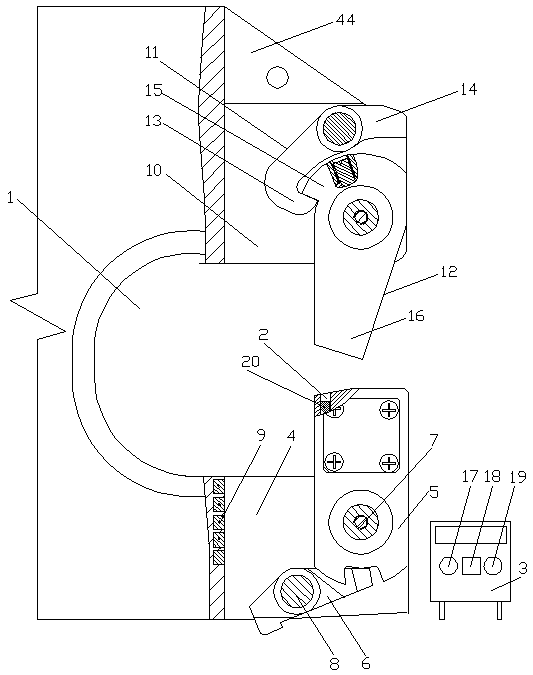

[0074] An anti-off and anti-single ring hoisting method, comprising the following steps:

[0075] a. Open the anti-off mechanism of the anti-off single ring lifting system, so that the anti-off mechanism is in the unlocked state;

[0076] b. When the lifting ring is installed into the ear hole 1 of the lifting lug on one side of the elevator, the sensing part 2 of the anti-loosening part sends out a signal, and after the controller 3 receives the signal, the controller 3 prohibits the movement of the traveling vehicle, and the traveling vehicle is in a stopped state; After the ring enters the ear hole 1, the anti-off mechanism is in a locked state, blocking the ring in the ear hole 1;

[0077] c. Put another lifting ring into the ear hole 1 of the lifting lug on the other side of the elevator, the sensing part 2 of the anti-off part sends out a signal, and the controller 3 allows the traveling vehicle to move after receiving the signal.

[0078] The anti-off single ring lifti...

Embodiment 3

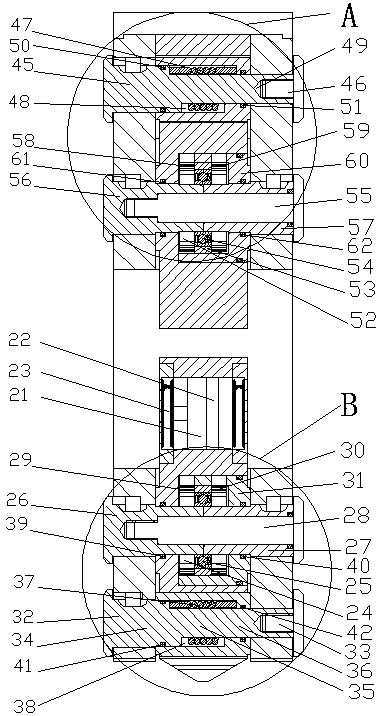

[0081] An anti-off and anti-single ring hoisting method, comprising the following steps:

[0082] a. Open the anti-off mechanism of the anti-off single ring lifting system, so that the anti-off mechanism is in the unlocked state;

[0083] b. When the lifting ring is installed into the ear hole 1 of the lifting lug on one side of the elevator, the sensing part 2 of the anti-loosening part sends out a signal, and after the controller 3 receives the signal, the controller 3 prohibits the movement of the traveling vehicle, and the traveling vehicle is in a stopped state; After the ring enters the ear hole 1, the anti-off mechanism is in a locked state, blocking the ring in the ear hole 1;

[0084] c. Put another lifting ring into the ear hole 1 of the lifting lug on the other side of the elevator, the sensing part 2 of the anti-off part sends out a signal, and the controller 3 allows the traveling vehicle to move after receiving the signal.

[0085] The anti-off single ring lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com