Vinasse fulvic acid and extraction method and application thereof

A technology of fulvic acid and distiller's grains, applied in the direction of chemicals, organic chemistry, and fungicides for biological control, to achieve the effect of inhibiting proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Take a quantitative amount of distilled grains (with a moisture content of 63.67wt%) provided by Gansu Jinhui Wine Industry Group in a 250mL conical flask, add 50mL distilled water and shake well, continue to add 1mL 0.5mol / L sodium pyrophosphate before use 1mol / L NaOH adjusts the pH value. Shake well and place it in a 40℃ water bath for extraction for 20min, centrifuge at 3900r / min for 15min, take the supernatant and filter (-0.07MPa, room temperature), adjust the pH of the filtrate to 2 with 1mol / L HCl. After cold sinking at 10°C for 12 hours, centrifugation was performed at 3900 r / min for 15 minutes, and the supernatant was collected as the DFA extract. Rotary evaporation is carried out at 55°C and -0.07MPa, and after concentration, it is frozen at -20°C for 48h, and then placed in a freeze dryer for drying at -40°C and 0.0001MPa to obtain distillers fulvic acid (DFA).

Embodiment 2

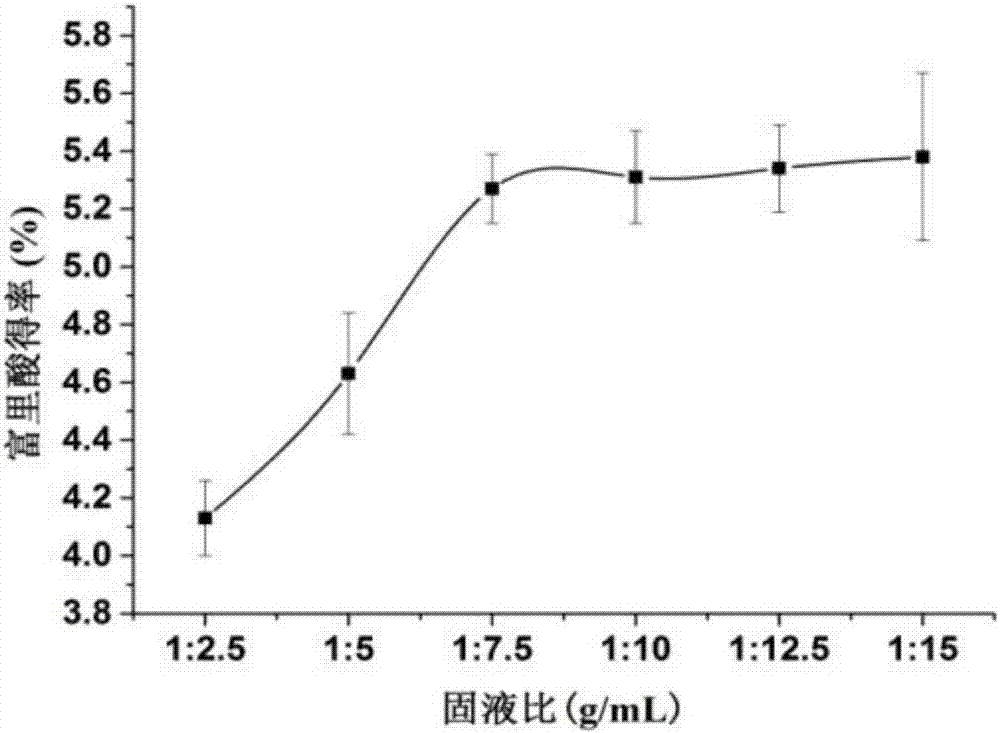

[0056] Taking the mass ratio of white wine grains and distilled water as the solid-liquid ratio, the pH value was controlled to 11, and the vinasse fulvic acid was extracted according to the method of Example 1. In this example, the solid-liquid ratio was controlled to be 1:2.5, 1:5, 1:7.5, 1:10, 1:12.5, and 1:15 respectively, and the yield of lees fulvic acid was calculated. figure 1 As shown, figure 1 It is the effect of solid-liquid ratio on the yield of vinasse fulvic acid.

[0057] by figure 1 The results show that when the mass ratio of distillers grains to water is 1: (2.5-15), the yield of distillers grain fulvic acid is 4.1-5.3%, and as the amount of water increases, the extraction rate of DFA also gradually increases. When the liquid ratio is 1:7.5, the DFA yield is the highest, and then gradually flatten out.

Embodiment 3

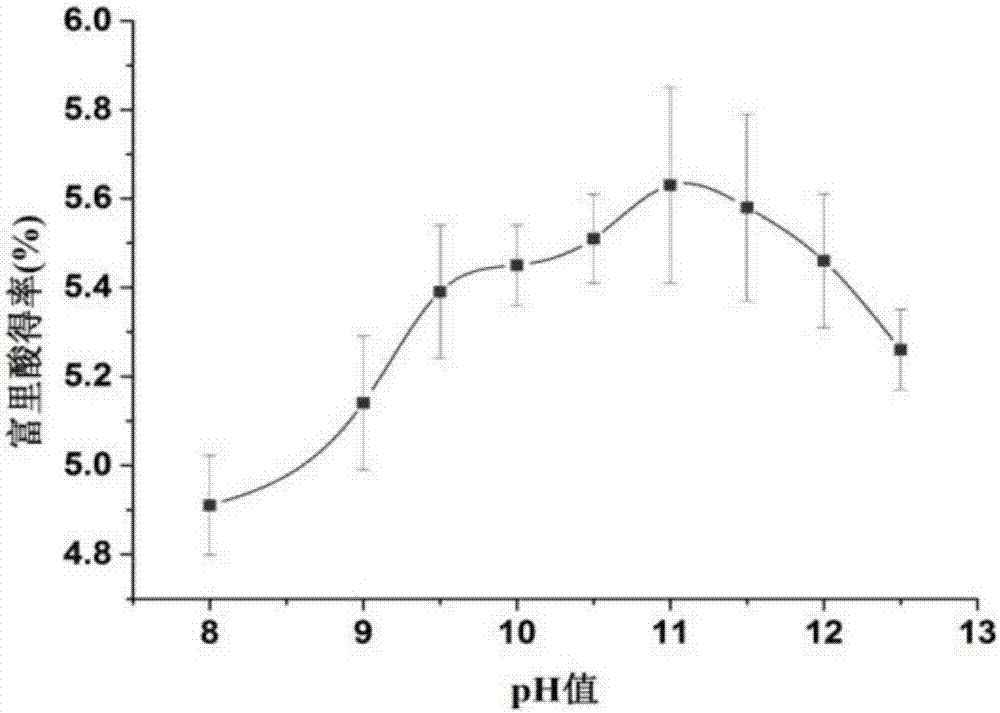

[0059] Extract the lees fulvic acid according to the method of Example 1, control the solid-to-liquid ratio to 1:7.5, and control the pH values of the alkaline distiller's lees to 8, 9, 10, 10.5, 11, 11.5, 12, 12.5, and calculate the lees fulvic acid Yield, the result is figure 2 As shown, figure 2 It is the influence of pH value on the yield of distillers grain fulvic acid.

[0060] by figure 2 The results show that when the pH is 8 to 12.5, the yield of lees fulvic acid is 4.9 to 5.65%. With the increase of pH value, the extraction rate of DFA increases first and then decreases. When the pH value is 11, the DFA yield is the highest. When the pH value is greater than 11, the decrease in the yield of DFA is due to the fact that after the alkali-soluble matter reaches saturation, more precipitates are precipitated during acid precipitation, which affects the yield of DFA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com