Bearing mechanism used for bearing material frame containing material

A bearing mechanism and material frame technology, applied in auxiliary devices, tool storage devices, auxiliary welding equipment, etc., can solve problems affecting workers' health, large waist injuries, and low production efficiency, so as to avoid waist injuries and reduce labor intensity , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

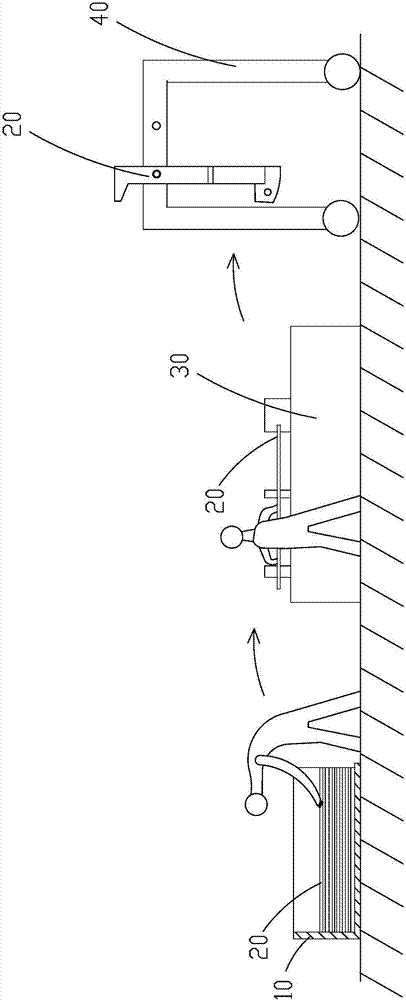

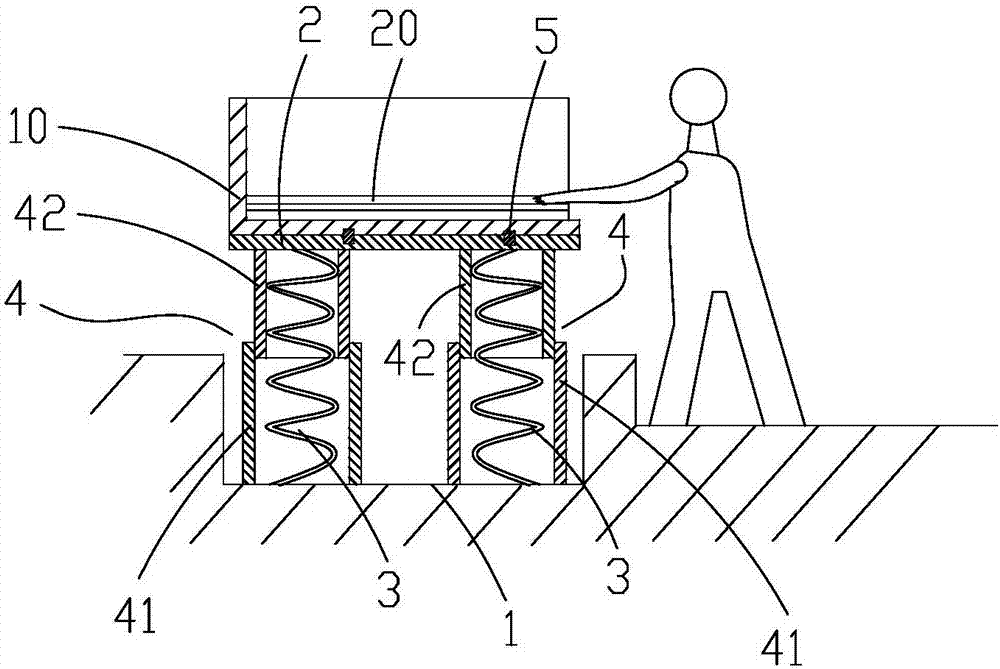

[0026] Such as figure 2 and image 3 As shown, a load-carrying mechanism for carrying a material frame containing materials includes a fixed support surface 1 and a load-carrying platform 2 for supporting the material frame 10. Between the support surface 1 and the load-bearing platform 2 The spring 3 that can gradually raise the carrying platform 2 when the material 20 in the material frame 10 gradually decreases. When the material frame 10 filled with material 20 is placed on the carrying platform 2, due to the large amount of material 20 and the heavy gravity, the spring 3 is compressed, and the deformation of the spring 3 is large, so the carrying platform 2 descends. After the carrying platform 2 descends and reaches a stable position, the worker can take the uppermost material 20 in the material frame 10 at a more comfortable position without bending over. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com