Machine manufacture device cutting state identification and data processing method

A technology of mechanical manufacturing and identification methods, applied in computer control, program control, general control systems, etc., can solve problems such as signal characteristics, nonlinear conversion relations, amplitude, frequency, shape, distribution differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

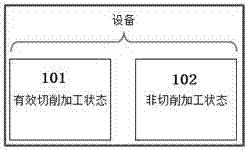

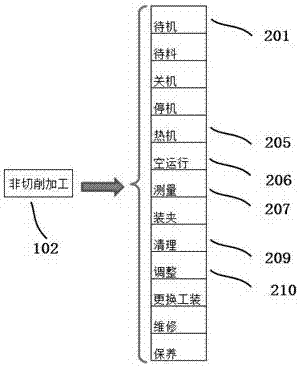

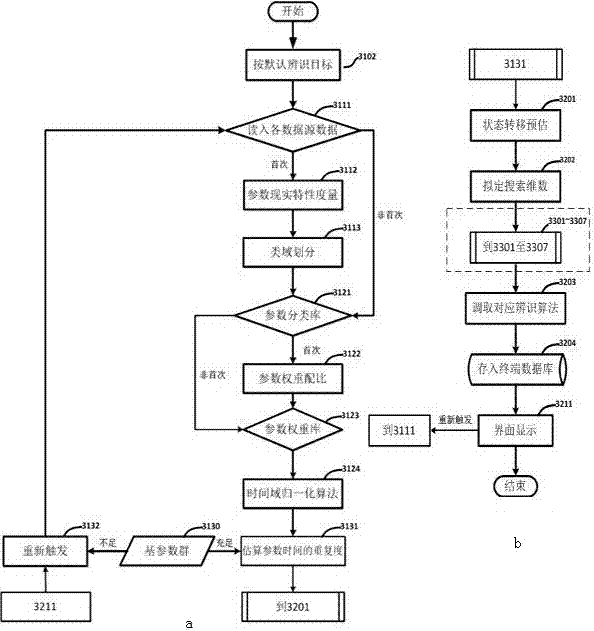

[0057] This case proposes a state identification target framework for mechanical processing equipment. On the basis of identification targets for cutting processing state and non-cutting processing state, a state recognition method is established, and a large number of data involved in the method are given. set of pretreatment programs. It mainly includes the following contents:

[0058] Collect on-site signals to the database. At the beginning of the system startup, the system defaults to extract the accumulated time of all the company's equipment in the cutting processing state in the previous 24 hours, and then trigger the system to filter the machining equipment in the designated area by clicking on the interface option Machining utilization over a specific time period.

[0059] Extract data from the database. If the parameter appears for the first time, predict the physical reality attributes of each data according to specific rules and algorithms, and initially divide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com