Model ice pushing device

A technology of pushing device and model, which is applied in the field of ship testing, can solve the problems of harsh navigation environment of ships in ice areas, fracture of ship shafting, etc., and achieve the effects of reducing influence, broadening research scope, and accurate test measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

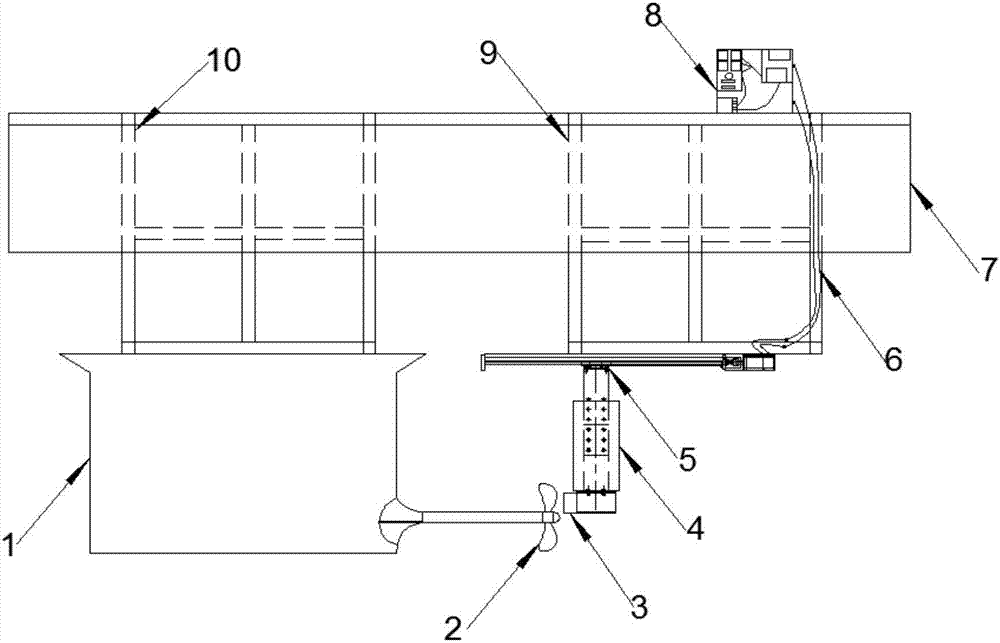

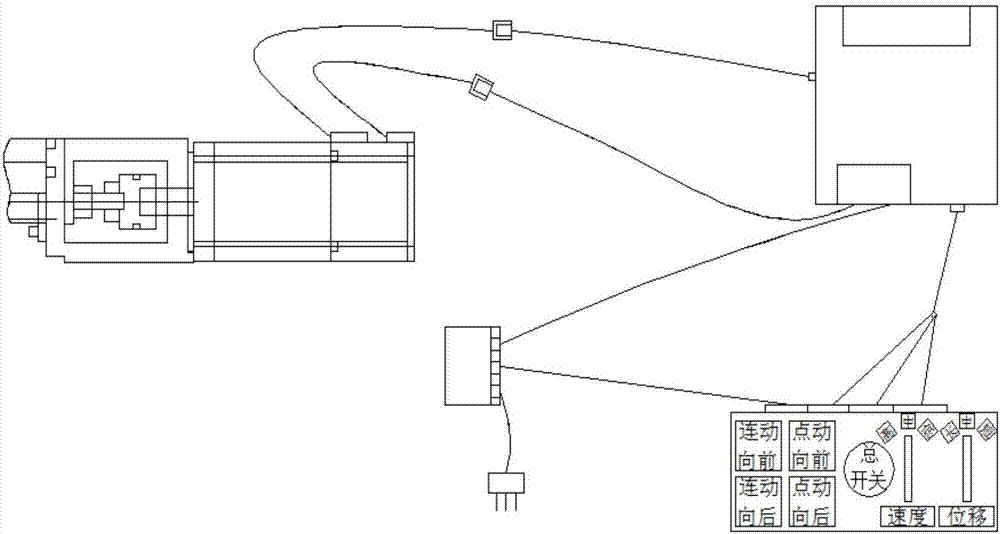

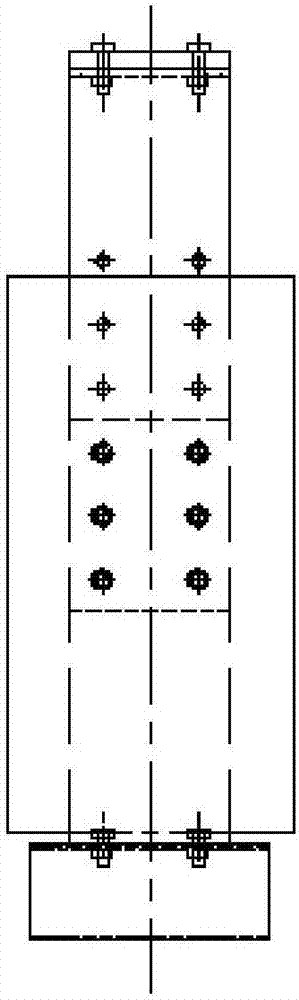

[0016] combine Figure 1 to Figure 4 , the new model ice pushing device of the present invention is composed of model ice fixing device 11, distance adjustable connector 12, linear module 18 and control system 8, the model ice fixing device is used to fix model ice of different sizes, is a three-sided Bending a groove-shaped member with an opening on one side, that is, the model ice fixing device 11 is composed of a flat plate and two U-shaped bars, the two U-shaped bars can be connected to the plate by screws, and through holes with different spacings are punched on the plate for easy application Because different tests require fixing model ice 3 of different sizes (length, width and thickness) and different shapes (spherical, square and elliptical, etc.), meanwhile, the flat plate of the model ice fixing device 11 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com