Multi-core fiber bragg grating (FBG) universal bending sensor

A multi-core fiber, universal bending technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems of increasing the number of sensors, increasing the number of sensors, and unable to fully compensate for the influence of temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

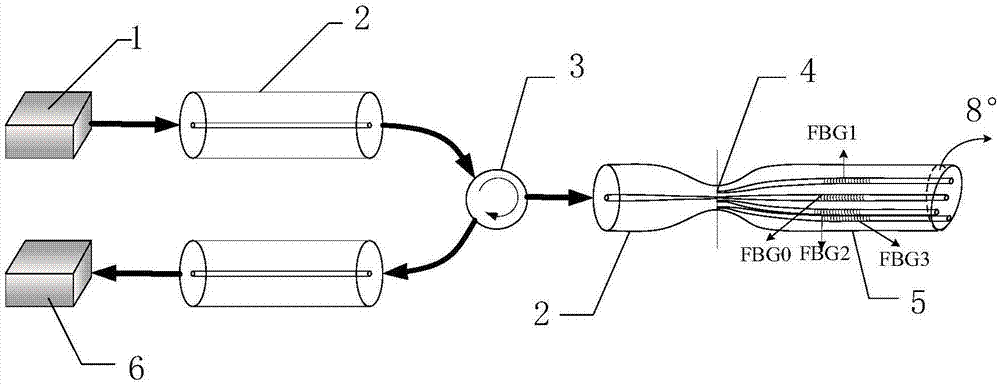

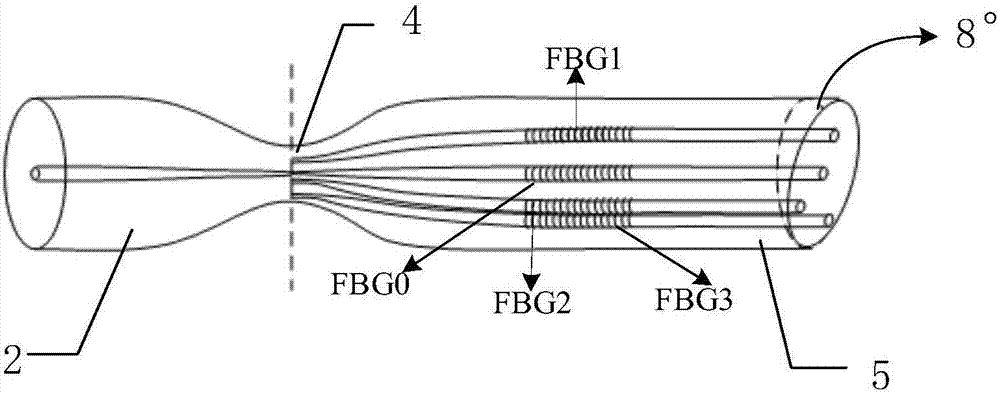

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] The invention uses multi-core fiber gratings with different reflection wavelengths for universal bending sensing, which not only solves the disadvantages of the previous fiber grating bending sensing that can only detect one to two angle changes, poor stability, and temperature crosstalk, but also has a probe Small size, strong anti-interference ability, light weight, built-in temperature compensation and other advantages.

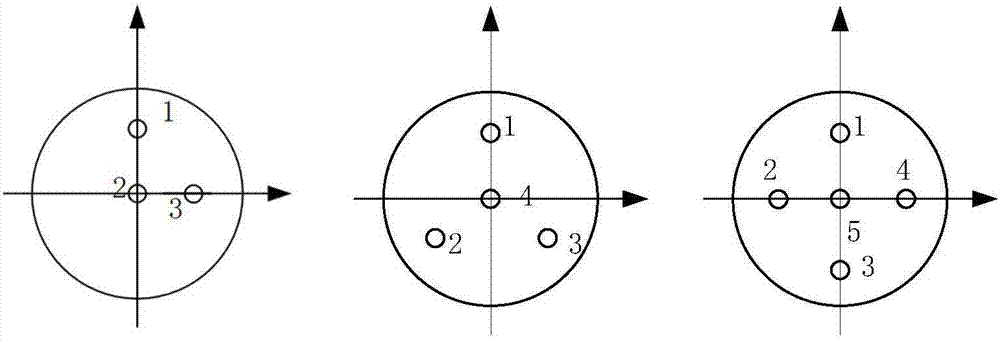

[0023] The fiber grating made of multi-core optical fiber can constitute the most compact gimbal bending sensor. Different from the technology reported in the recent literature, this project intends to use multi-core optical fibers with slightly different core refractive indices to produce the same periodic structure of fiber gratings, and then write multiple groups of different reflection wavelengths along the same multi-core optical fiber....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com