Sealing structure of wedge-shaped blocking cover

A technology of sealing structure and blocking cover, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc. It can solve the problems of affecting the appearance, small contact area of metal seals, and riveting points on the appearance, so as to increase the sealing contact area and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

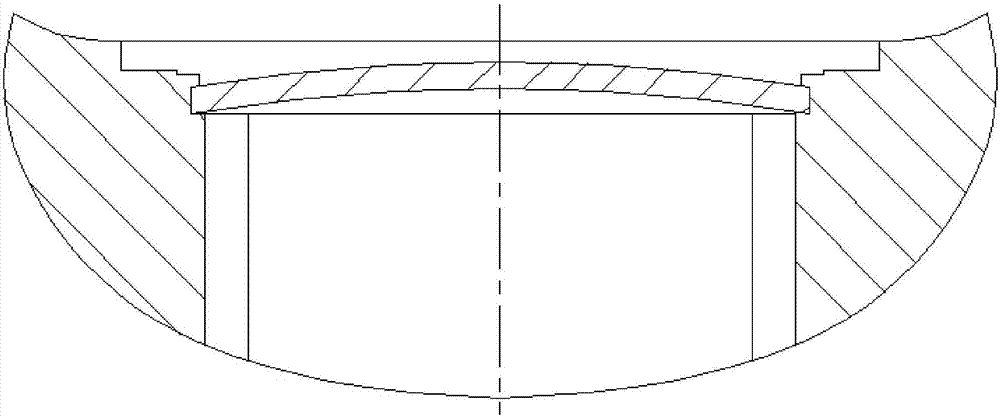

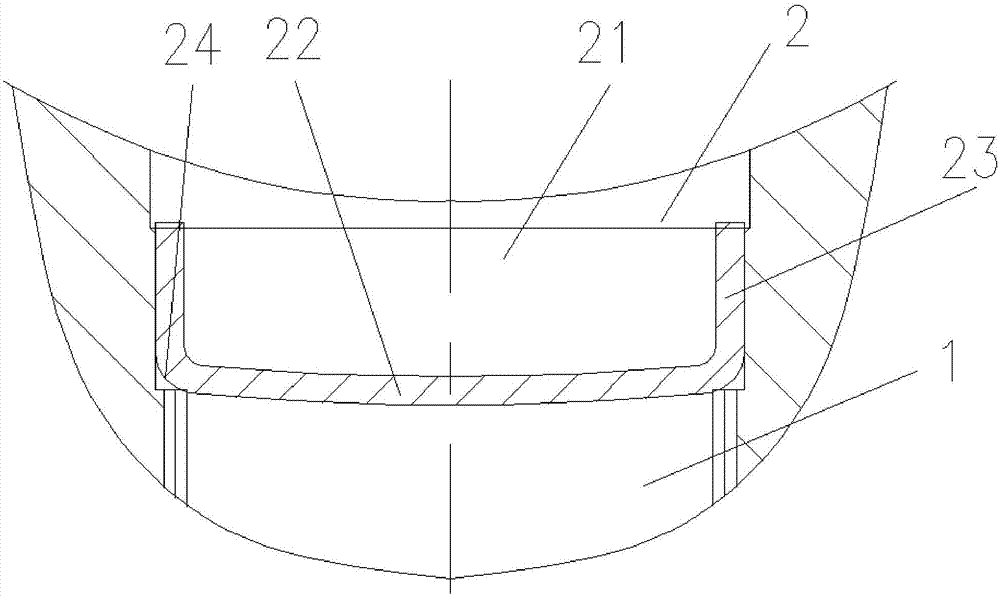

[0011] The present invention will be described in detail below in conjunction with accompanying drawing: figure 2 As shown, the present invention includes a pit 1 and a plugging cover 2. The plugging cover 2 is a bowl-shaped structure, and the plugging cover 2 is pressed into the pit 1. The opening 21 of the plugging cover 2 faces upwards, and the plugging cover 2 The bottom end is sealed in the pit 1; the outer wall 23 of the blocking cover 2 and the pit 1 are interference fit.

[0012] The bottom surface 22 of the blocking cover 2 is a tapered surface, and the two ends of the bottom surface 22 are in close contact with the two ends of the pit 1 .

[0013] The transition between the outer wall 23 of the blocking cover 2 and the bottom surface 22 is through a circular arc 24 .

[0014] The sealing process of the present invention is as follows: 1. Adopt the plugging cover 2 of bowl-shaped structure, and the bottom surface 22 has a taper; The cover is pressed into the pit 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com