A method for measuring the expansion speed of horizontal well sagd steam chamber

A technology of expanding speed and steam chamber, which is applied in earthwork drilling, wellbore/well components, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

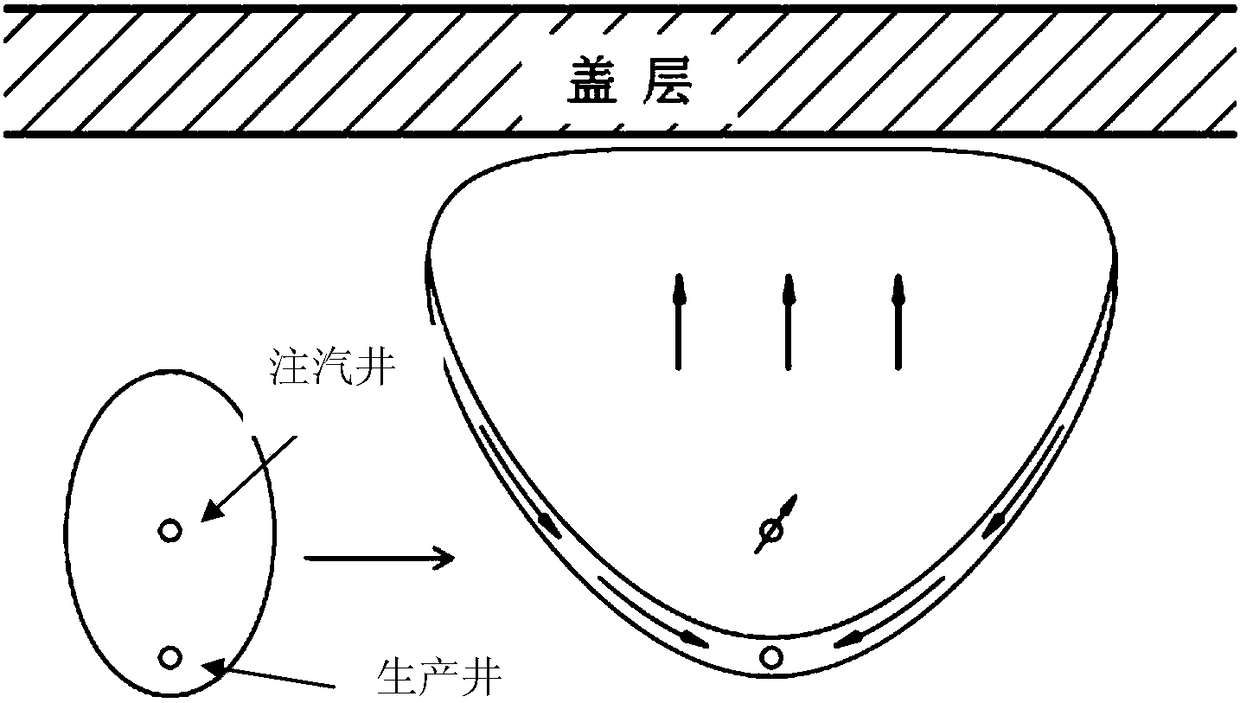

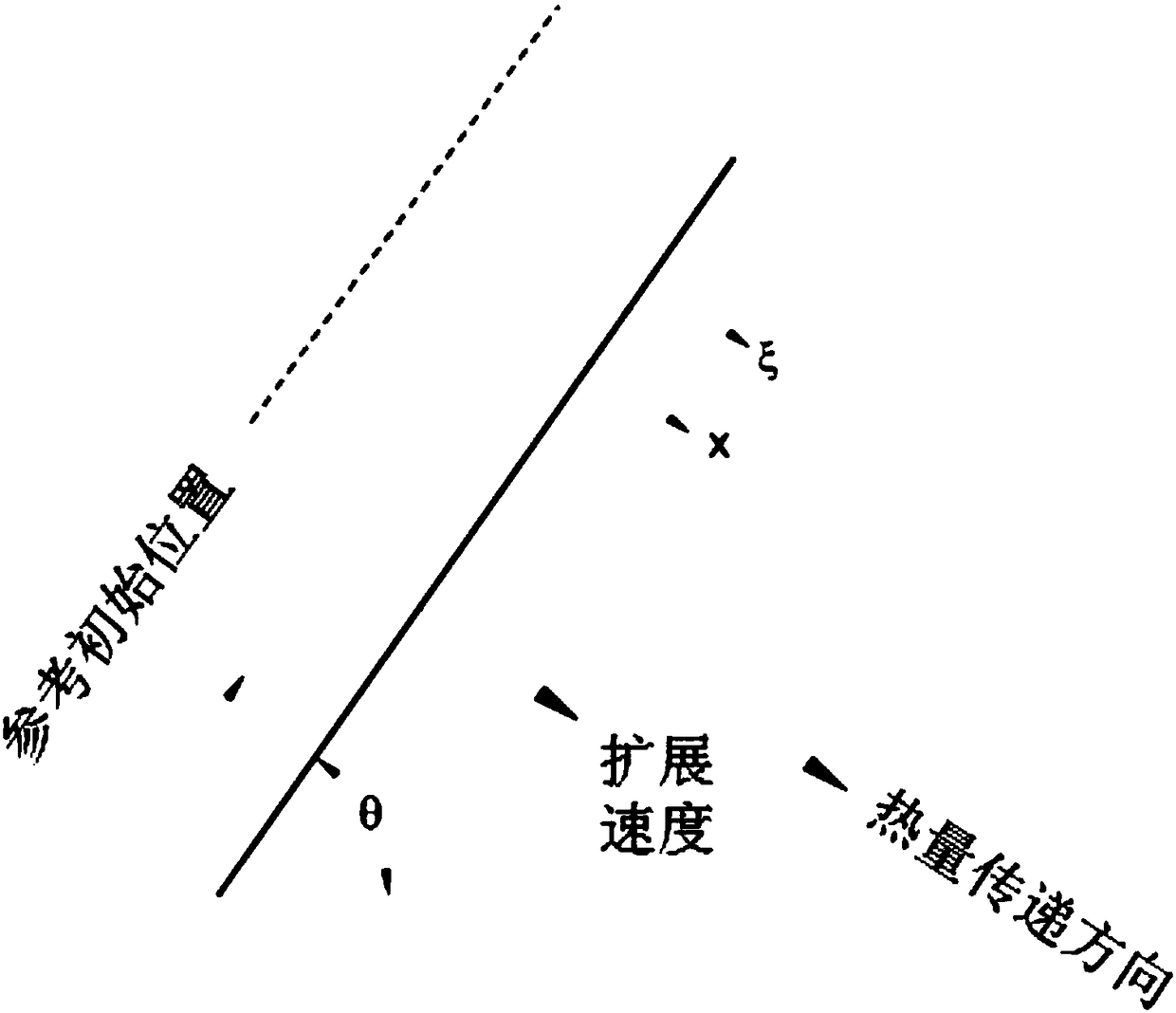

Problems solved by technology

Method used

Image

Examples

Embodiment 1

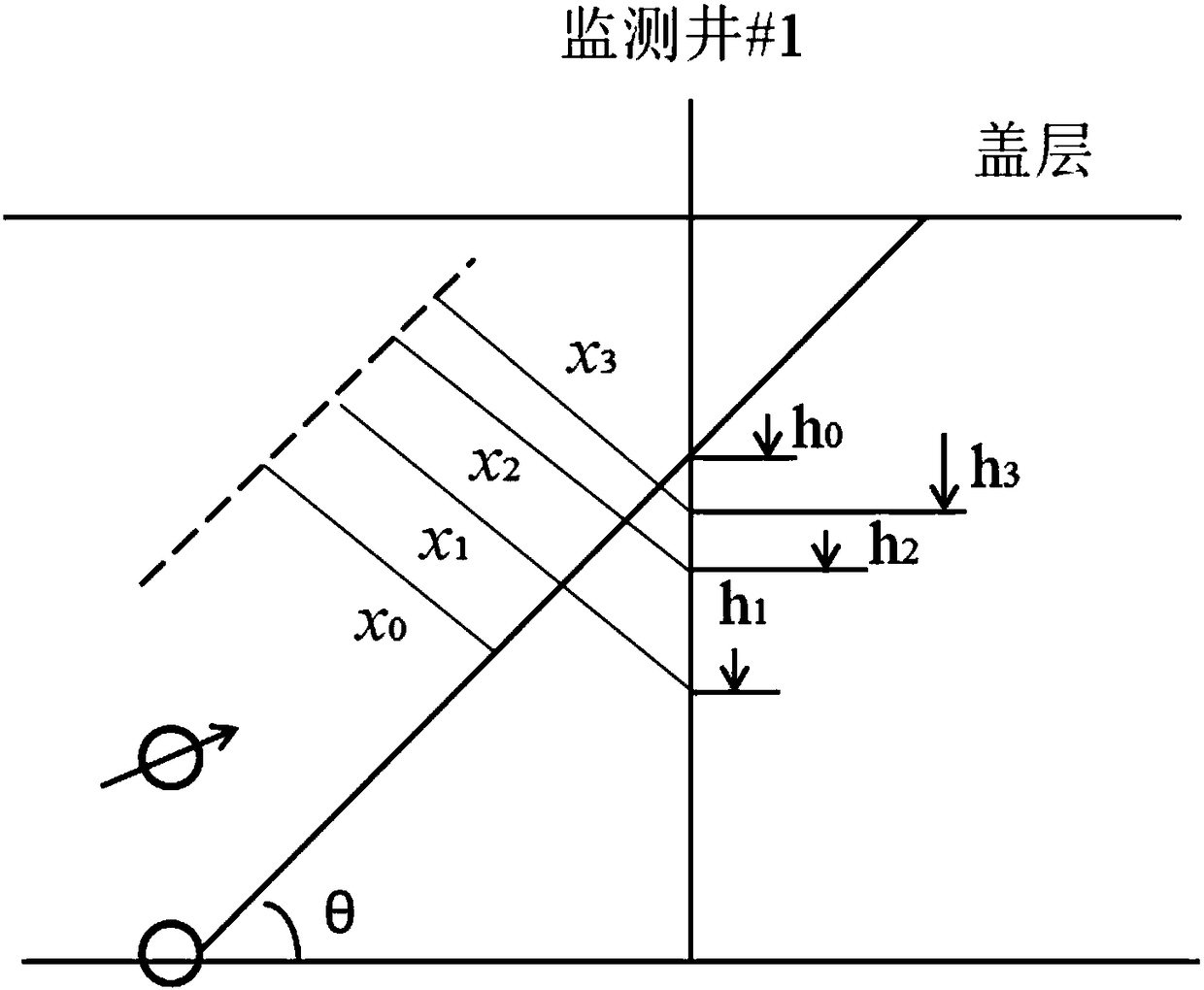

[0095] Taking a steam injection production project of a horizontal well group in a certain well area as an example, the vertical temperature distribution at a distance of 13.9 meters from the horizontal injection well can be detected through the corresponding observation well. The temperature of the steam chamber is set at 250°C, the original temperature of the reservoir is 15°C, and the depth of the production well is 350 meters.

[0096] According to the observation well data, select the data in the following table (three time nodes, six monitoring point data for each time node):

[0097] Table 1 Observation well depth-temperature data

[0098]

[0099] (1) Physical parameters

[0100] The oil layer corresponding to the horizontal well group has a porosity of 29.7%, a permeability of 1078.1mD, and an oil saturation of 70%. The physical properties of crude oil and rock are shown in Table 2.

[0101] Table 2 Observation well depth-temperature data

[0102]

[0103] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com