Supporting method for crushed surrounding rock mining roadway in three-soft coal seam goaf

A technology for mining roadways and three-soft coal seams, which is applied in tunnels, tunnel linings, mining equipment, etc. to reduce secondary disturbances, improve support strength, and promote stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0019] The invention provides a roadway support method for broken surrounding rock in the goaf of the three-soft coal seam.

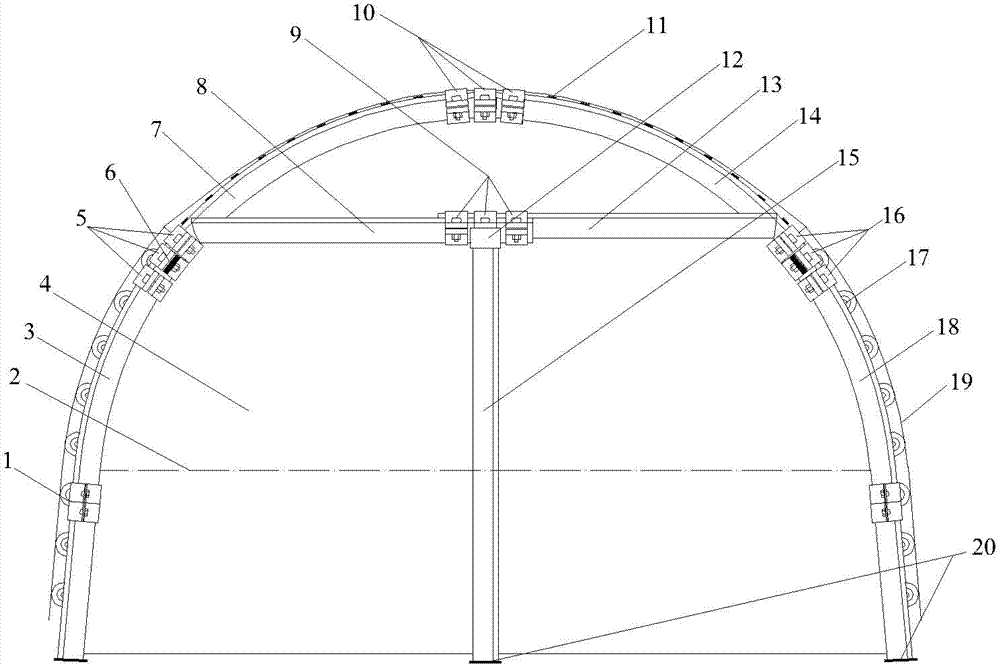

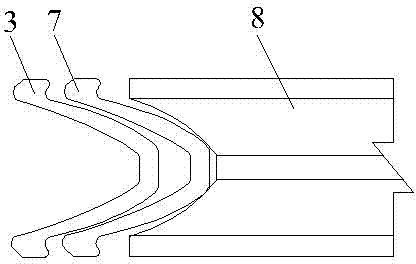

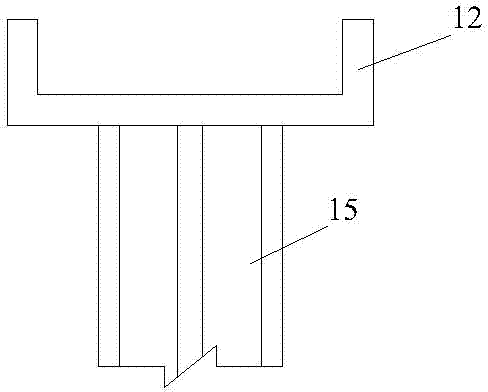

[0020] Such as Figure 1~3 Shown, the specific embodiment of the present invention comprises the following steps:

[0021] Step 1: Design the section shape of the mining roadway 4 in the goaf of the three soft coal seams as a semicircular arch, the arch line 2 of the mining roadway 4 section has a gross width of 4600mm, a lower gross width of 4900mm, a gross height of 3400mm, and a gross sectional area of 13.9m 2 , mining roadway 4 net section arching line 2 net width 4200mm, bottom width 4500mm, arching line 2 to bottom plate 1100mm, arching line 2 to vault center 2100mm, column socket 50mm, tie angle 85°, net sectional are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com