A method for strengthening the lifting girder of double-track prefabricated box girder of high-speed railway

A high-speed railway and box girder technology, applied in bridge reinforcement, bridges, bridge materials, etc., can solve the problems of concrete cracking, unsatisfactory effect, affecting the appearance and durability of the structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of this patent will be further described in detail below.

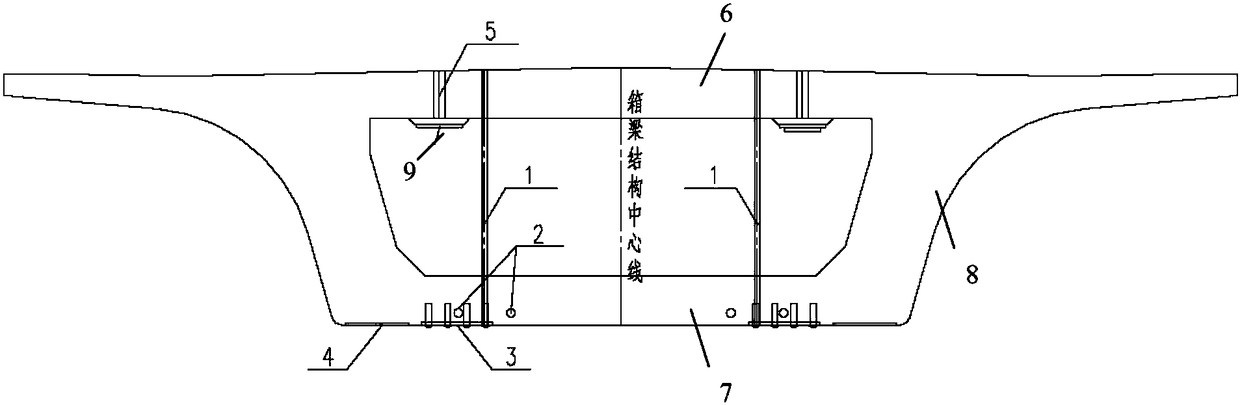

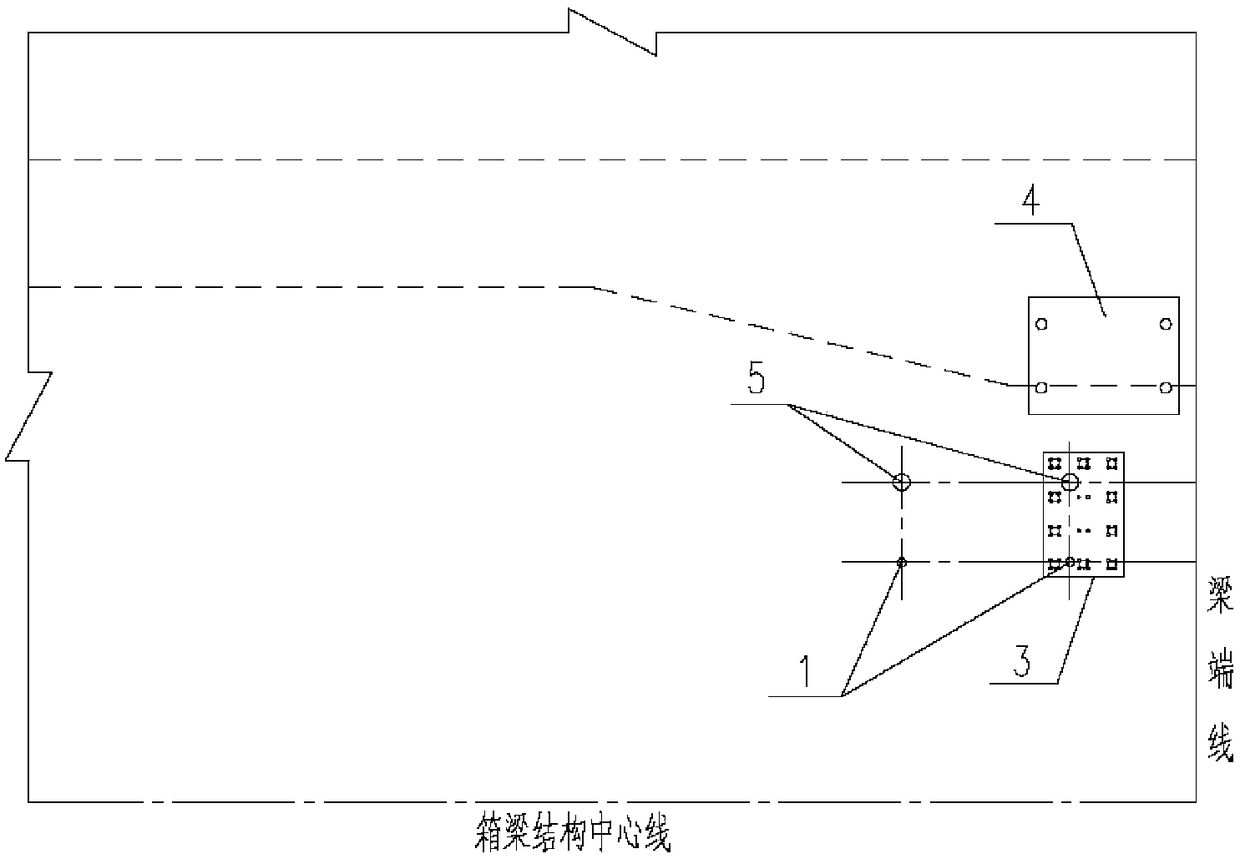

[0024] Such as figure 1 and 2 As shown, a high-speed railway double-line prefabricated box girder beam reinforcement method, according to the structure of the prefabricated box girder to determine the layout of the beam lifting hole 5, the layout of the longitudinal prestressed steel bundle 2, the layout of the embedded sleeve 3 of the anti-fall beam stopper And the layout of the embedded steel plate 4 of the support. When in use, it is hoisted by installing a hook at the 5 lifting holes of the beam, and adding a hanging pre-embedded steel plate 9 below the 5 lifting holes of the beam to increase the strength. The specific methods include:

[0025] Before lifting the girder of the prefabricated box girder, external prestress is applied between the top plate 6 and the bottom plate 7 of the box girder, so that the concrete at the joint between the top plate 6 and the web 8 of the box girder is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com