Garlic sprout harvester

A harvester and garlic sprout technology, applied in the field of agricultural machinery, can solve the problems of high labor intensity, high cost, low efficiency, etc., and achieve the effects of reducing labor costs, reducing harvesting costs and improving harvesting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

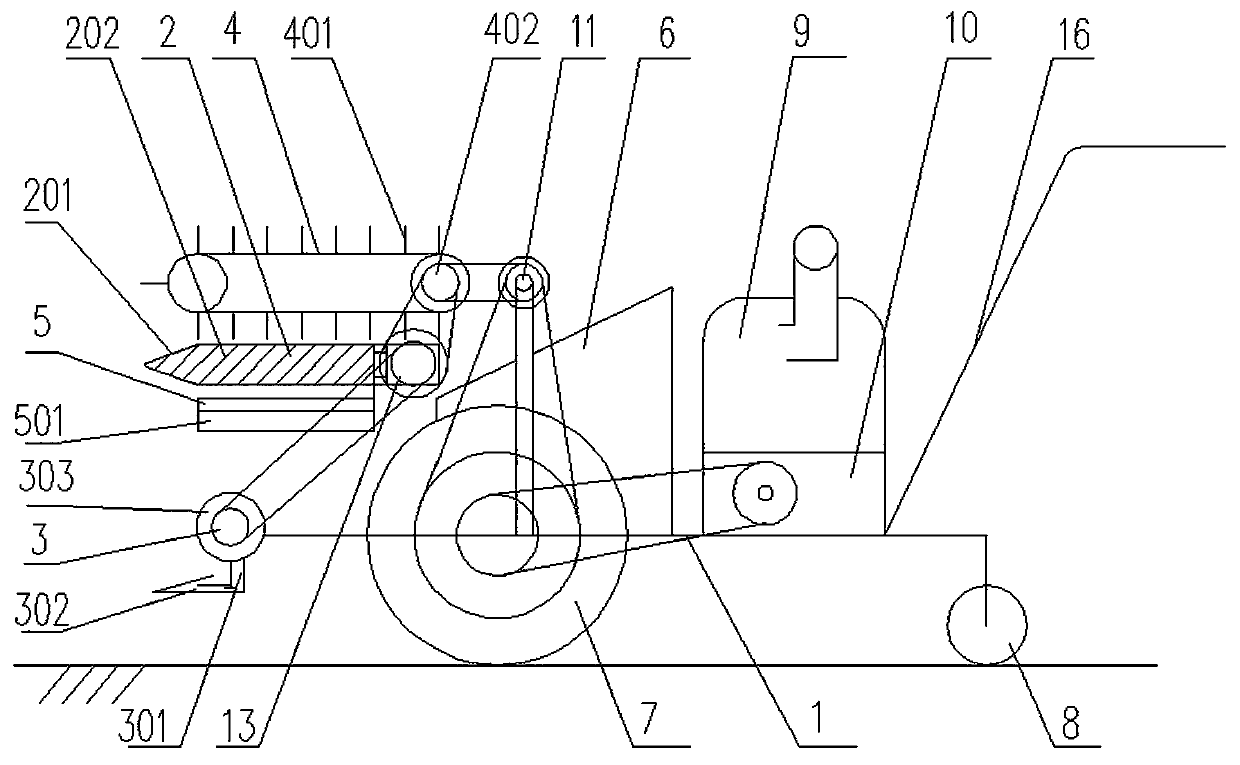

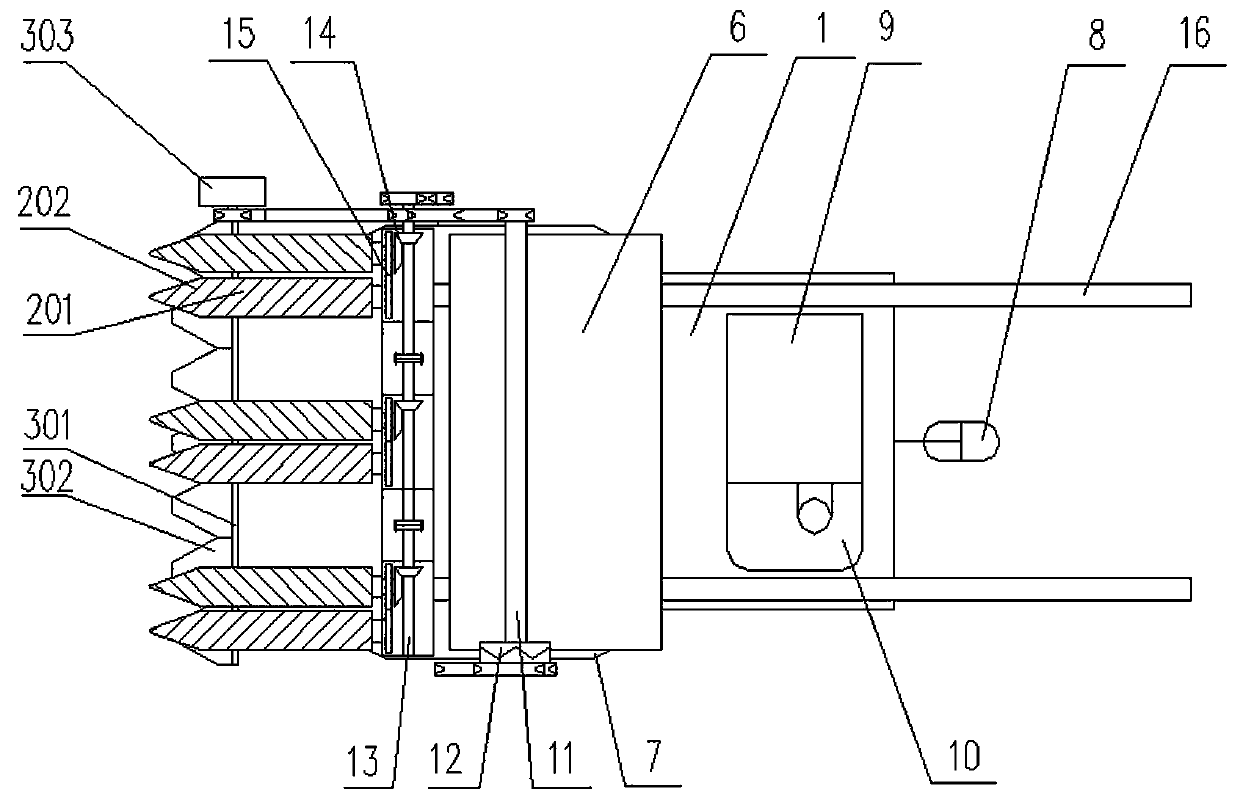

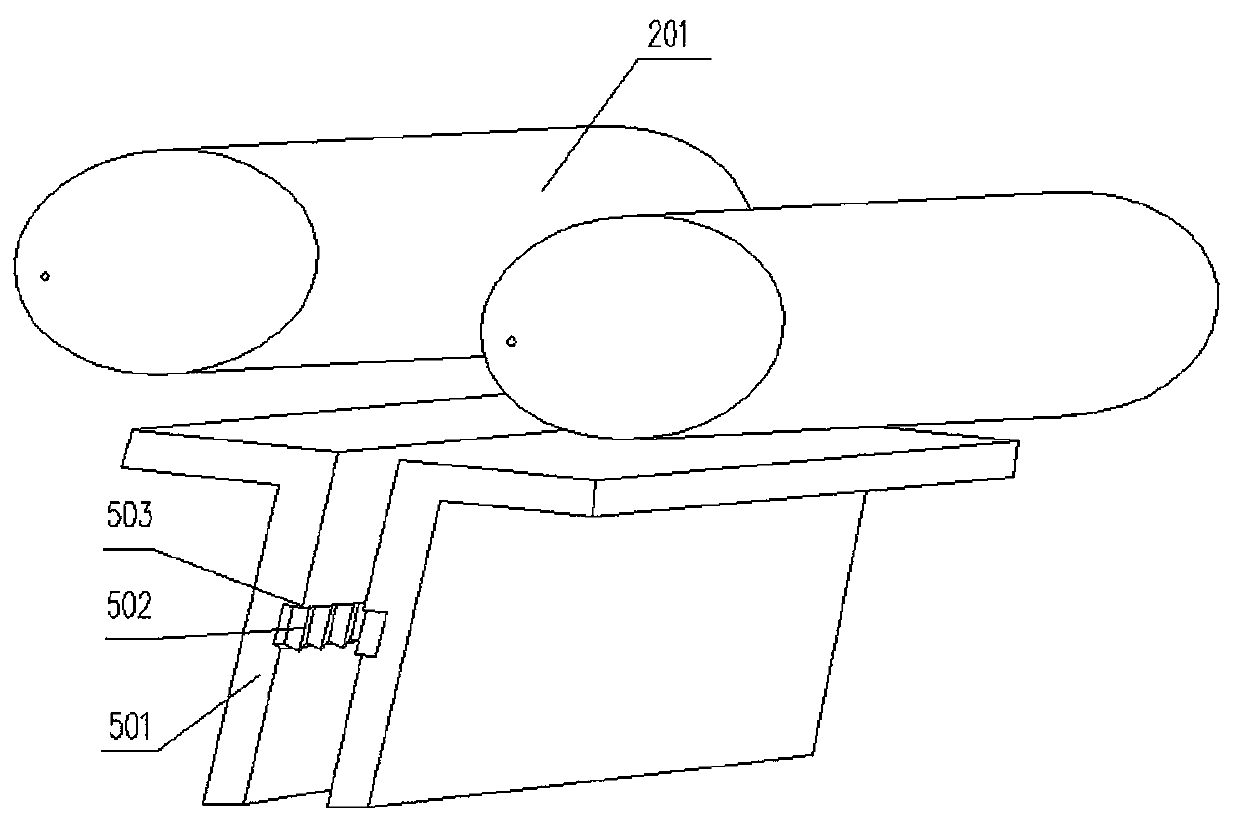

[0022] Such as Figure 1 to Figure 3 As shown, a garlic sprout harvester of the present invention includes a vehicle frame 1, and a conveying device 4, a bolting device 2, a peeling device 5 and a swinging knife device 3 are sequentially arranged at the front end of the vehicle frame 1 from top to bottom. A harvesting box 6 is arranged at the end of the conveying direction of the conveying device 4 on the vehicle frame 1 . The vehicle frame 1 is also provided with an engine 9 and a gearbox 10 connected to the engine 9. The output shaft of the gearbox 10 drives two traveling wheels 7 positioned at both sides of the vehicle frame 1 to rotate and advance through a chain structure. The rear end middle part is provided with a ground tug wheel 8 driven to advance, and the rear end of vehicle frame 1 is also provided with the handrail 16 that is used for grasping the direction of travel of the present invention.

[0023] The bolting device 2 is used to gather and lift the scattered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com