Conveying device for adjusting height of inlet through changing of angle

A technology of changing the angle and conveying device, applied in the direction of conveyor, transportation and packaging, etc., to avoid tilt, avoid excessive production cycle, and achieve the effect of exquisite design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

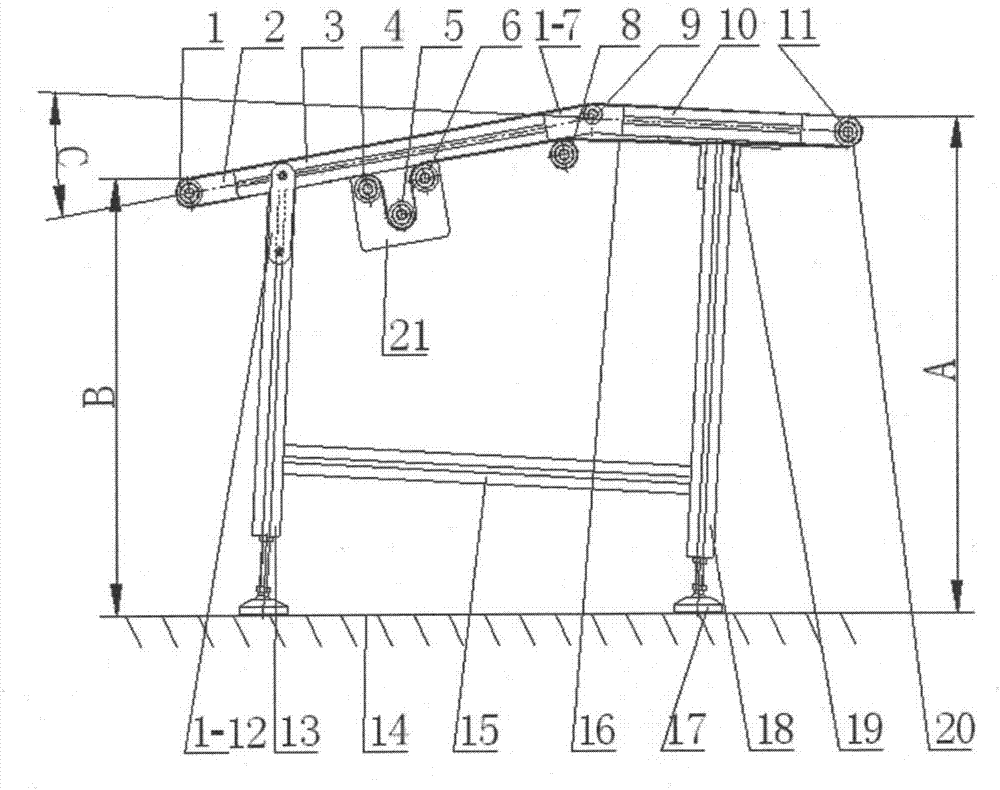

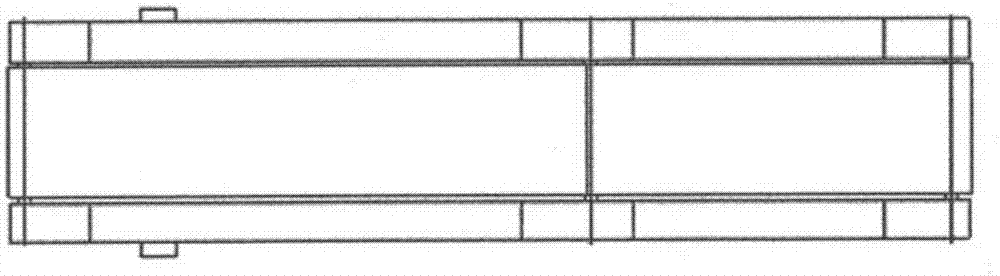

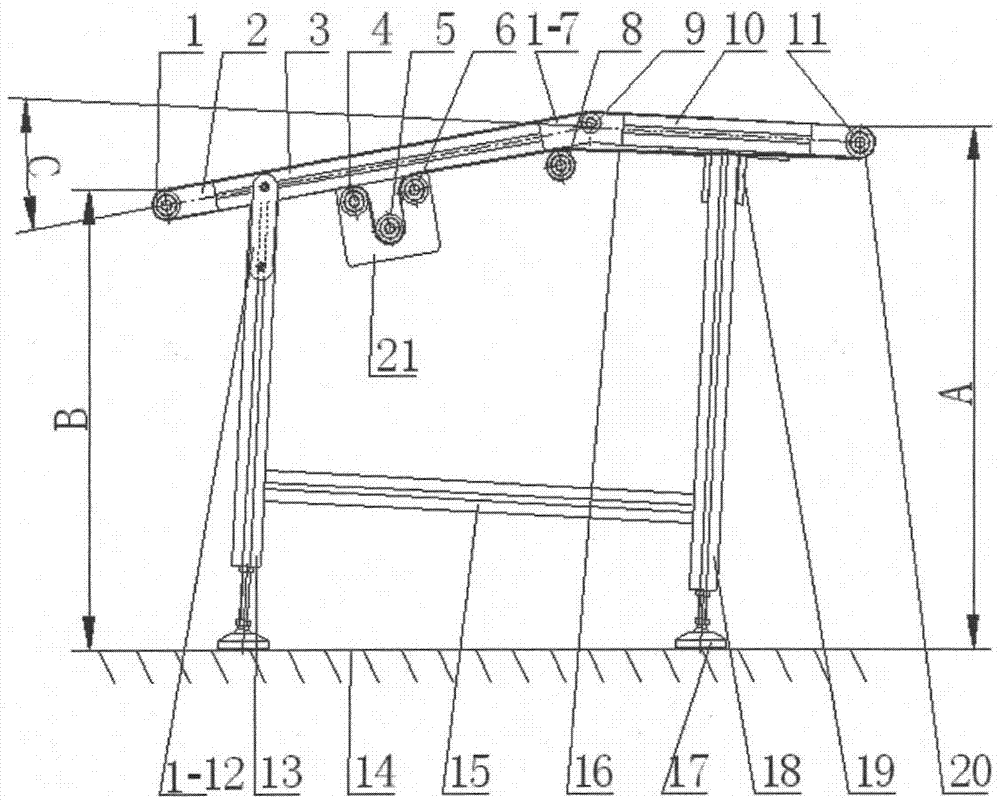

[0019] The invention is a conveying device that adjusts the height of the entrance by changing the angle, such as Figure 3-1 , Figure 3-2 As shown, it includes the first driven roller 1, the first driven roller bearing housing 2, the first profile 3, the first idler roller 4, the driving roller 5, the second idler roller 6, and the fourth idler roller swing Bearing housing 2-7, third roller 8, fourth roller 9, fourth roller fixing seat 22, second profile 10, second driven roller 11, profile connector 2-12, third profile 13 , the fourth profile 15, the conveyor belt 24, the adjustment foot 17, the fifth profile 18, the rolling bearing 20, the driving roller bearing seat 21, the second driven roller bearing seat 14.

[0020] The first profile 3 and the second profile 10 are connected by a hinge mechanism, the first profile 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com