Special lathe support frame for worm rod machining

A special lathe and support frame technology, which is applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problem of tedious and inaccurate angle adjustment of the whirlwind milling support frame, and achieve simple structure, easy adjustment, and rotation prevention The effect of plate rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

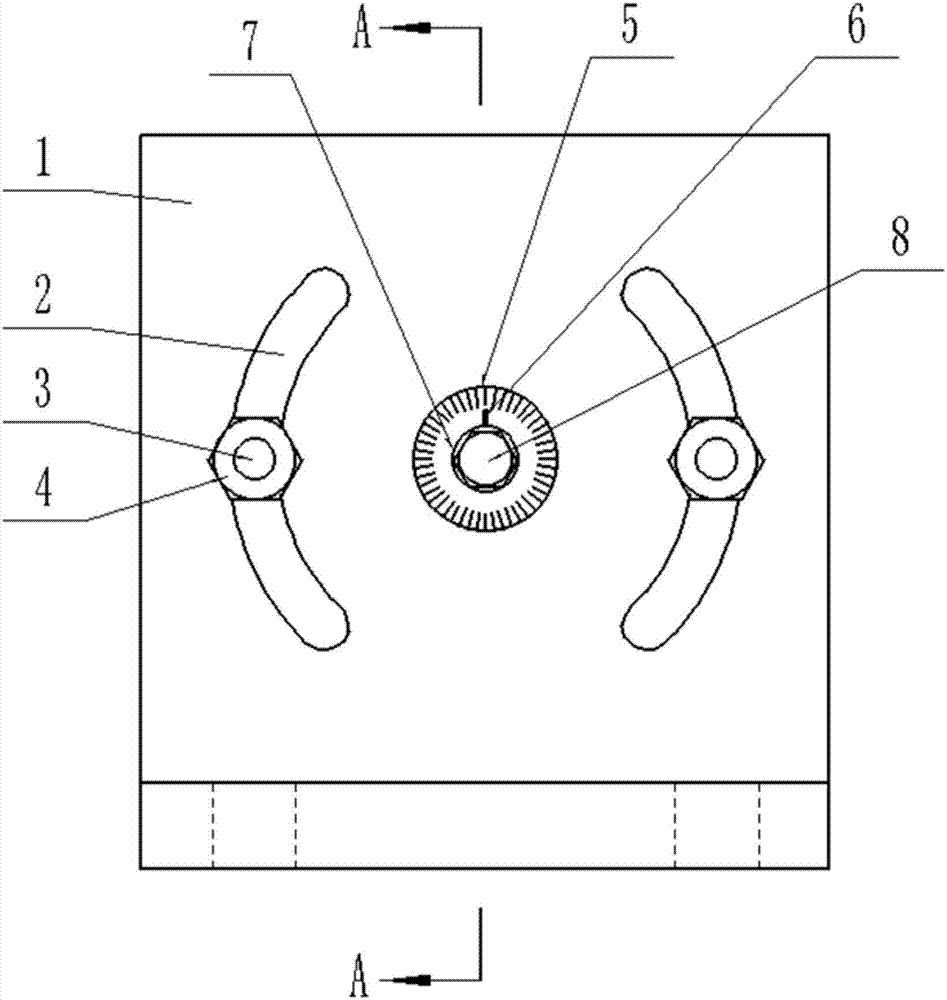

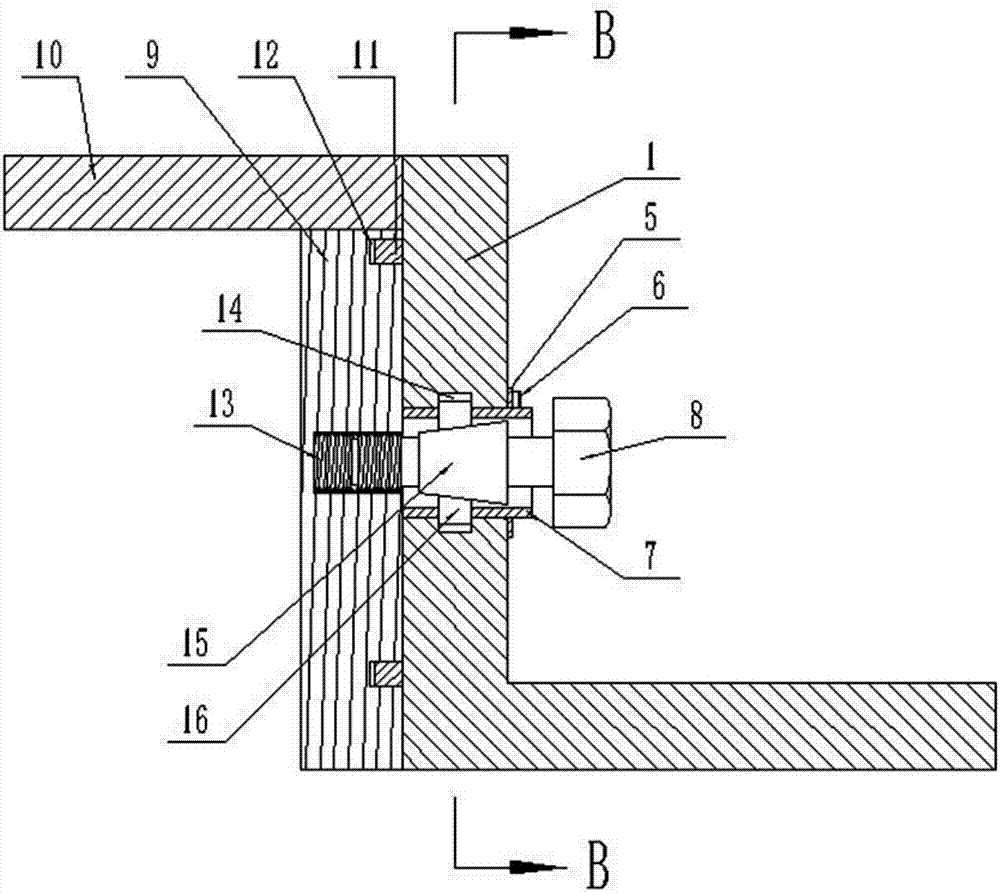

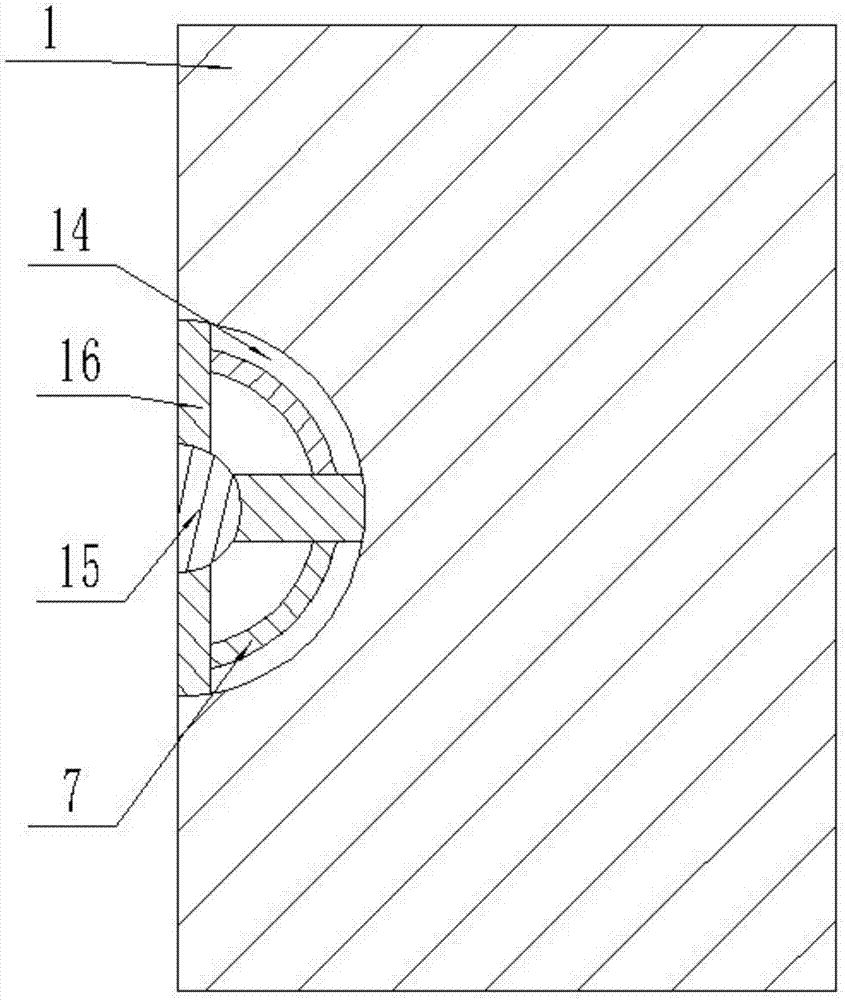

[0021] Such as figure 2 As shown, the special lathe support frame for worm processing includes the first support plate 1 whose lower end is bent to the right, the left side of the first support plate 1 is provided with an annular protrusion 11, and the left side of the first support plate 1 is provided with a The rotating plate 9 is provided with a supporting plate 10 perpendicular thereto, the right side of the rotating plate 9 is provided with an annular groove 12 cooperating with the annular protrusion 11, and the annular protrusion 11 is arranged in the annular groove 12, The right side of the rotary plate 9 is provided with a shaft sleeve 7 coaxial therewith, and the shaft sleeve 7 extends rightward through the first support plate 1 and the dial 5 provided on the right side of the first support plate 1. The dial 5 The shaft sleeve 7 on the right side is provided with a pointer 6, and the bolt 8 passes through the shaft sleeve 7 and is threadedly connected with the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com