Intelligent flexible assembly unit

A flexible assembly, intelligent technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as increasing the operating cost of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

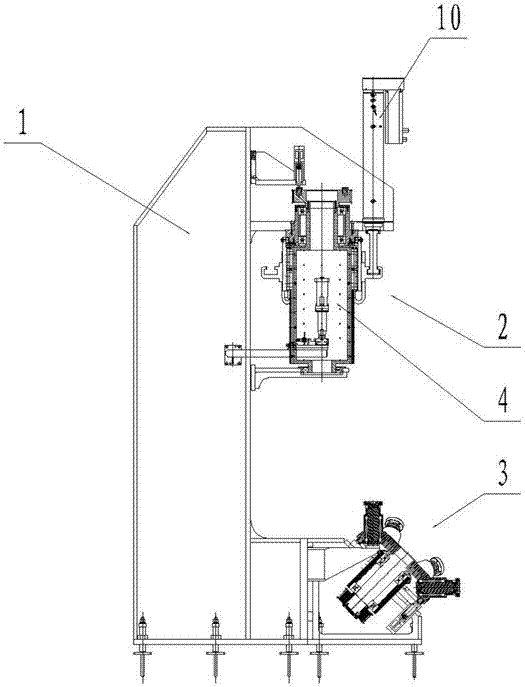

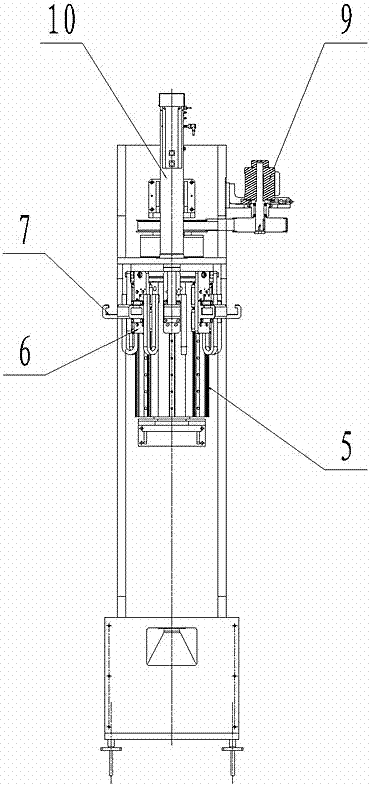

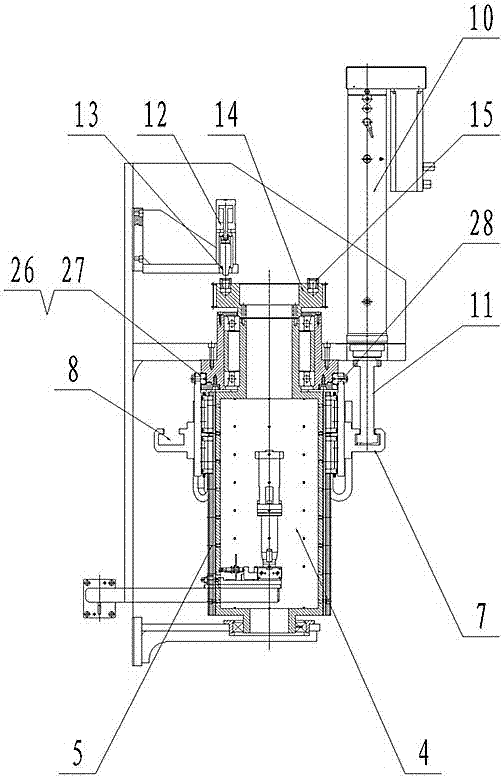

[0017] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figures 1 to 6 Shown: an intelligent flexible assembly unit, including a frame 1 as the basis, a press-fit mechanism 2 is arranged on the upper part of the frame 1, and a counter-rest mechanism 3 is arranged on the lower part of the frame 1, and the press-fit mechanism 2 is matched with the back mechanism 3,

[0018] The above-mentioned press-fitting mechanism 2 includes a rotary drum 4 that is rotatably supported on the frame 1. On the outer wall of the rotary drum 4, a plurality of longitudinally arranged slide rails 5 are evenly distributed, and each slide rail 5 is slidably connected with a sliding seat 6, and a horizontally distributed pressing block 7 is arranged on the outside of the sliding seat 6, and an inverted T-shaped hole 8 is opened on the pressing block 7, and a drum motor 9 is also arranged on the frame 1, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com