Assembling type variable cross-section expanding and withdrawing slip form system and construction method thereof

A variable cross-section and assembled technology, which is applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., can solve the problems that affect the construction speed and construction quality, the large volume of fixed sliding form trusses, and the harsh natural conditions of construction, etc., to achieve Good energy saving and environmental protection effect, saving construction materials, good construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

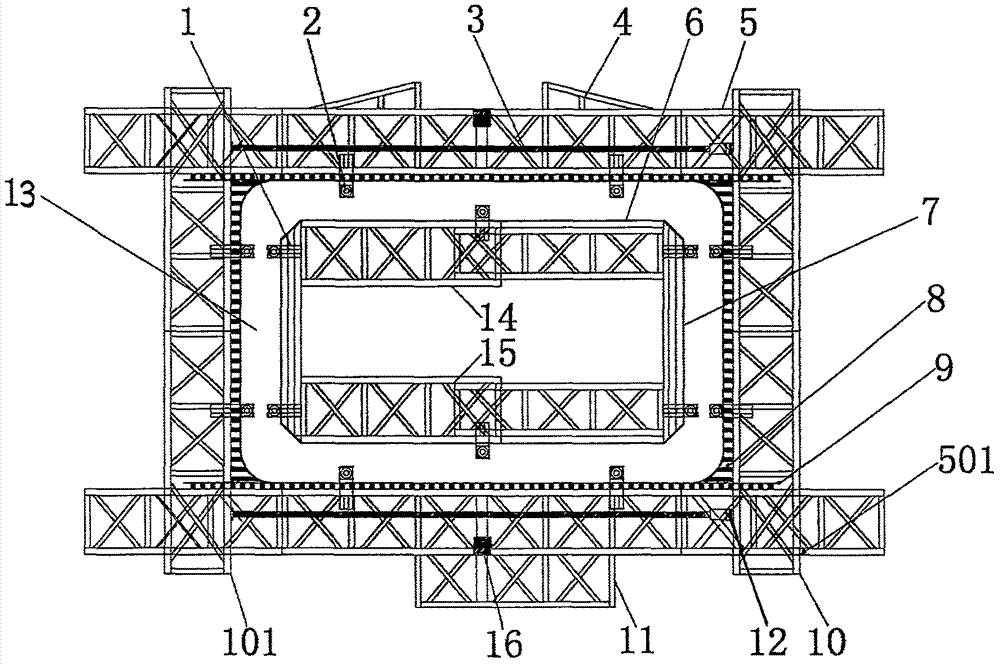

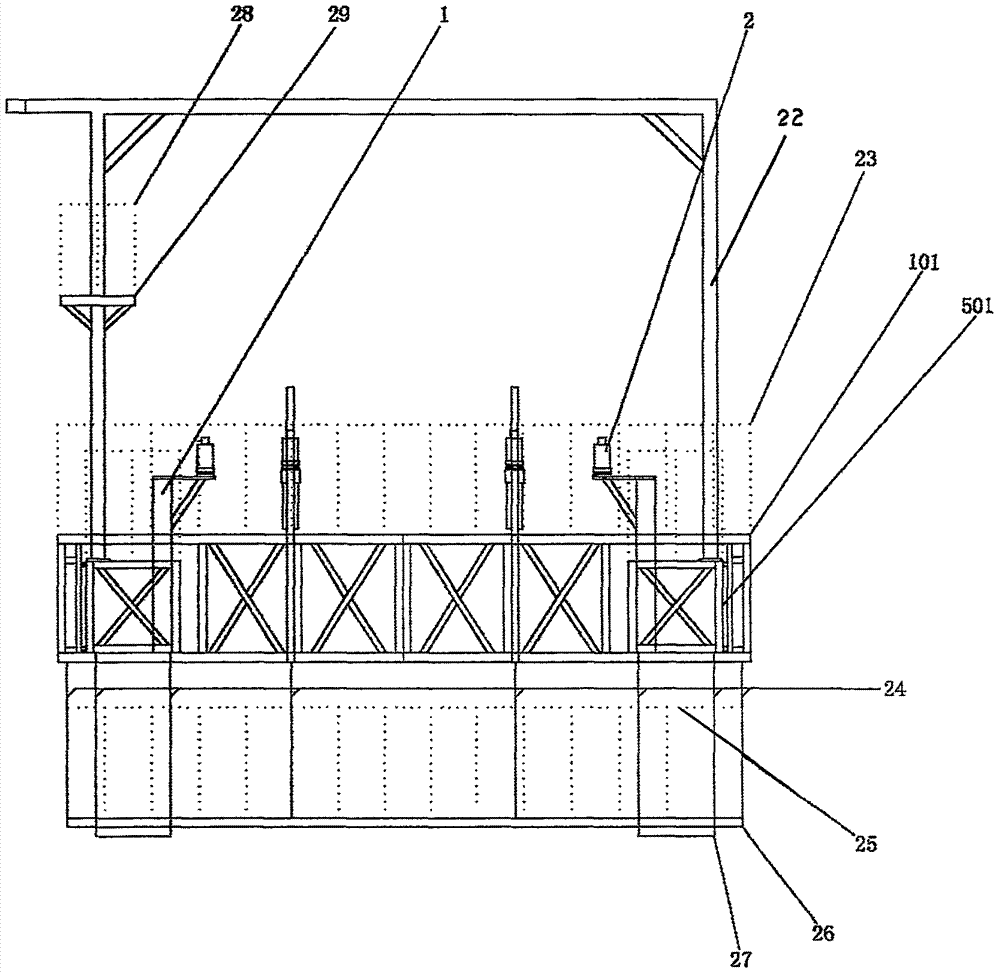

[0042] Such as Figure 1 to Figure 11 As shown, the present invention includes an electric welding machine 34, an operating table 36 and a distribution box 37, wherein:

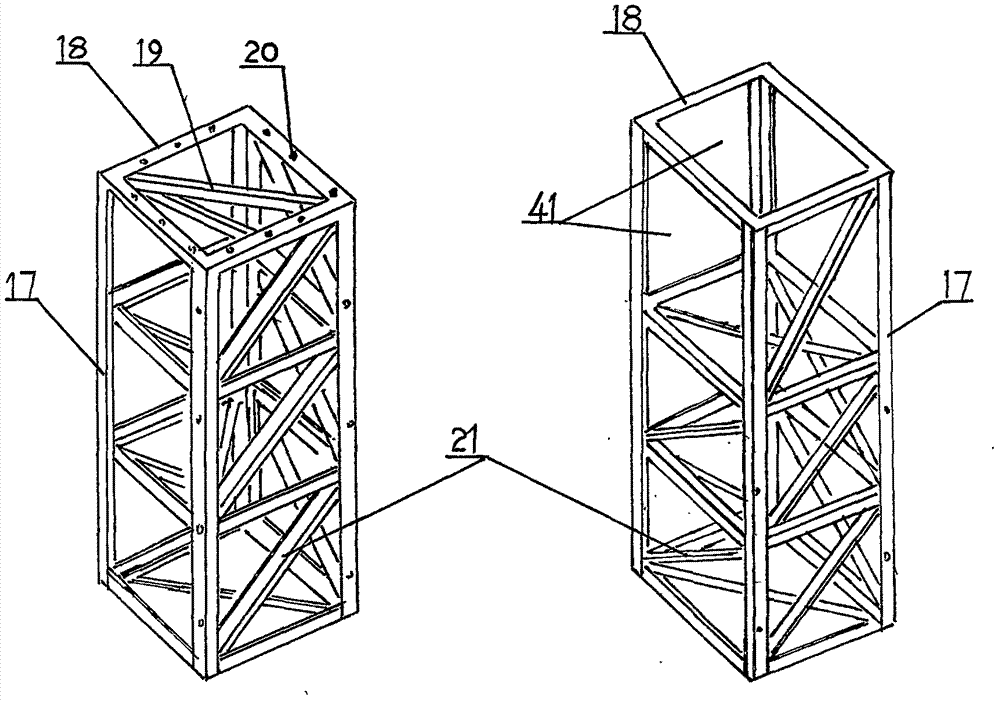

[0043] Assembled frame: the assembled frame is four angular steel rectangular frames 18 distributed at intervals, and the four corners are evenly distributed and fixed on the upper and lower ends of the four angle steel columns 17 and between the upper and lower ends. Reinforcing angle steel 19 is provided between the opposite corners of the angle steel rectangular frame. Parallel cable-stayed angle steels 21 are arranged between the opposite corners of the same plane angle steel columns between the upper and lower angle steel rectangular frames. One end of several assembled frames is provided with a space frame 41 for inserting and sliding an assembled frame of another size from the side or the front. The space frame can be located in the forward direction and the side of the assembled frame, and the space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com