Steel sheet film strain test force-applying apparatus

A film stress and force application device technology, which is used in measuring devices, using stable tension/pressure to test material strength, force/torque/work measuring instruments, etc. problem, to achieve the effect of simple operation and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

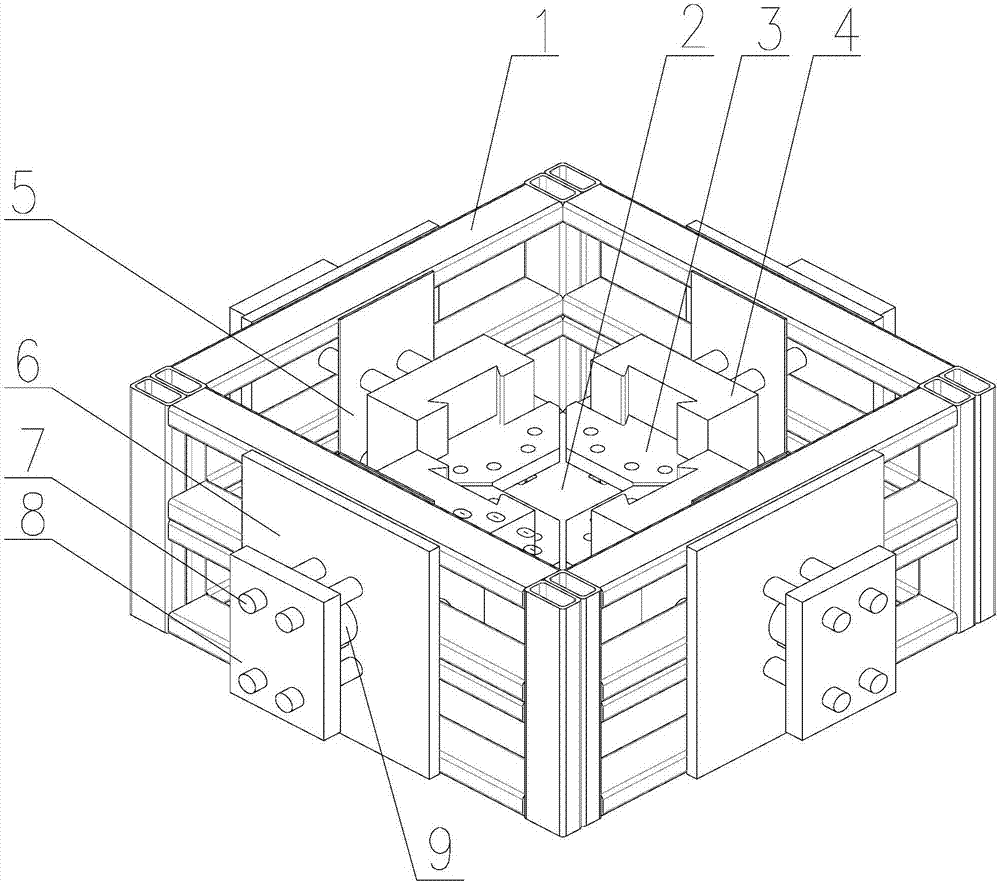

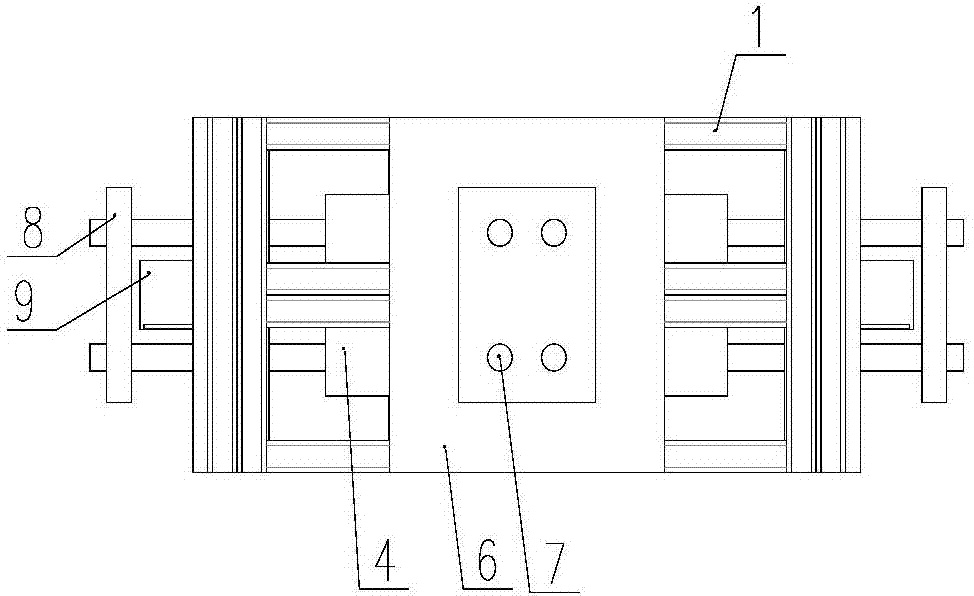

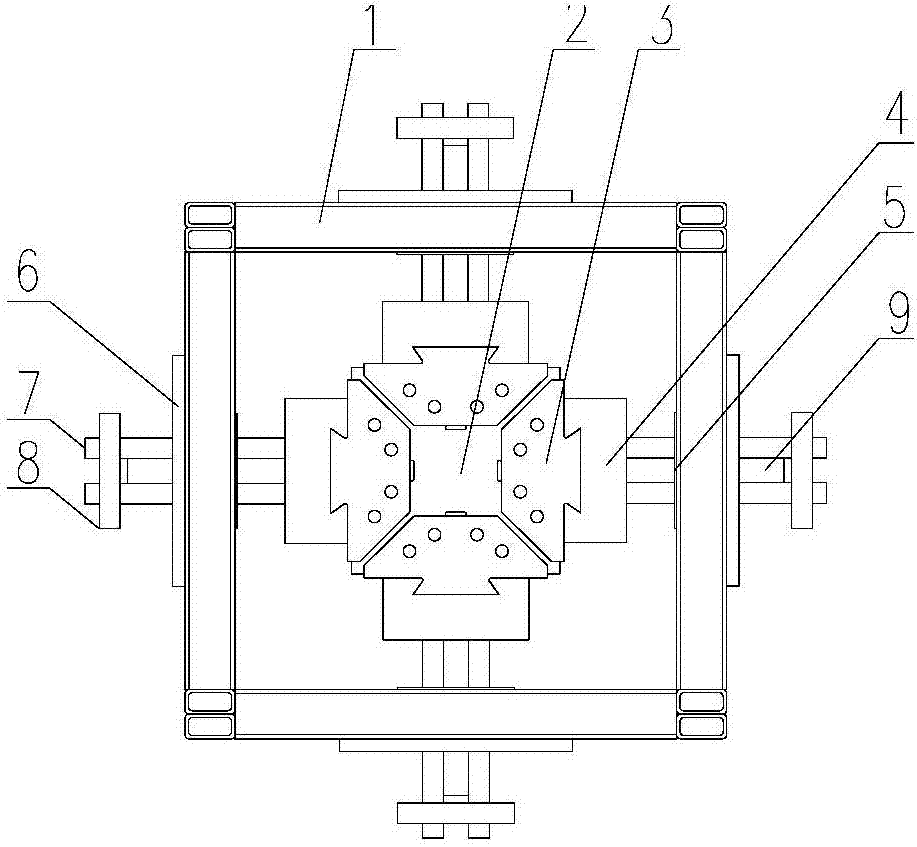

[0022] Such as Figure 1a , 1b As shown in , 1c, the force applying device for steel plate film stress test includes: back-shaped steel frame 1, sliding dovetail fixture 3, dovetail groove guide rail 4, guide plate 5, frame strengthening side plate 6, force transmission stud 7, receiving top plate 8 and hydraulic jack 9; the structure of each side of the steel plate film stress test force device is the same, and the structure of each side is symmetrical to the axis, that is, the structure is both centrally symmetrical and axially symmetrical; the steel plate tensile test piece 2 consists of two upper and lower sliding dovetail fixtures 3 clamping, sliding dovetail fixture 3 can slide up and down along the dovetail groove guide rail 4 and can adjust the horizontal height, driven by the hydraulic jack 9 and moved outward by the top plate 8, and the dovetail groove guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com